Shielding With Aluminum Foil

Shielding With Aluminum Foil Related Searches

Aluminum Foil For Shielding Wrapping With Aluminum Foil Tricks With Aluminum Foil Aluminum Foil Coated Aluminum Foil Rf Shielding Aluminum Foil As Insulation Foam With Aluminum Foil Heat Shield Aluminum Foil Saving Aluminum Foil Wrapped In Aluminum Foil Paint With Aluminum Foil Proper Way To Use Aluminum Foil Aluminum Foil On Face Painting With Aluminum Foil Rf Shielding Aluminum Foil Aluminum Foil For Insulation Grounding With Aluminum Foil Tips For Using Aluminum Foil Appearance Of Aluminum Foil Aluminum Foil Suit Grilling Using Aluminum Foil Sealed Aluminum Foil Freezing With Aluminum Foil Aluminum Foil Wrap Tanning With Aluminum Foil Aluminum Foil For Packaging Aluminum Foil Side Facing Sheet Of Aluminum Foil Aluminum Foil Hats Washing Aluminum FoilShielding With Aluminum Foil Supplier & Manufacturer from China

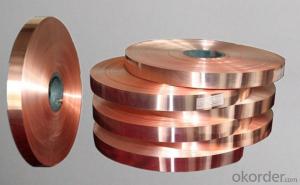

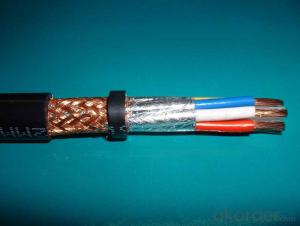

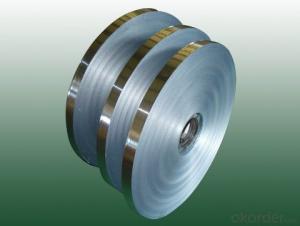

Shielding With Aluminum Foil is a versatile product that offers excellent protection against electromagnetic interference and radio frequency interference. This product is widely used in various industries, including electronics, telecommunications, and aerospace, to shield sensitive equipment and components from unwanted signals and noise. It is also commonly used in the food industry for preserving freshness and maintaining the quality of food products. The aluminum foil's reflective properties make it an ideal material for this purpose, as it effectively blocks out external radiation and heat.In numerous application and usage scenarios, Shielding With Aluminum Foil proves to be an indispensable solution. It is often employed in the construction of Faraday cages, which are enclosures designed to block electromagnetic fields. These cages are crucial in laboratories and other sensitive environments where the integrity of electronic equipment must be maintained. Additionally, aluminum foil is used in the packaging of various products to protect them from external factors that could compromise their quality. This is particularly important in the food industry, where maintaining freshness and preventing spoilage is paramount.

Okorder.com is a leading wholesale supplier of Shielding With Aluminum Foil, boasting a substantial inventory to cater to the diverse needs of customers. The company prides itself on offering high-quality products at competitive prices, ensuring that clients receive the best value for their investment. With a commitment to customer satisfaction, Okorder.com is dedicated to providing exceptional service and support to its clientele. By partnering with Okorder.com, businesses can rest assured that they are sourcing their aluminum foil shielding needs from a reliable and reputable source.