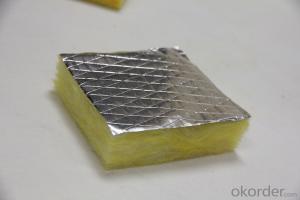

Aluminum Foil Facing Rock Wool Board for Wall Partition of Highly Valued Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. INTRODUCTION

CMAX ROCK WOOL are widely used in public, commercial an residential building as well as industrial plants, for applications such as roofing, external wall, partion wall and floating floor to provide fire protection, thermal insulation, acoustic control and condensation control.

2. FEATURES

● Thermal Insulation

● Fire Safety

● Acoustic Control

● No Corrosion

● Environmental friendly

● Moisture Resistance

● Energy Conservation & Emissions Reduction

3. CMAX ROCK WOOL BLANKET & BOARD STANDARD SIZE

PRODUCT | BLANKET | BOARD |

Density(Kg/m3) | 60-100 | 40-200 |

Thickness(mm) | 30-150 | 30-100 |

Size:L*W(mm) | 1200*3000-6000 | 600*1200 |

Remark:

Other sizes are available unpon request. Facing materials can be applied unpon request.

4. PRODUCTION THECHNOLOGY

CMAX rock wool is made from natural rocks such as basalt and limestone. The rocks are melted in a cupolaat temperature of >1450℃, and the molten lava is fiberized by a spinner. The inorganic fibers are bondedtogether using a thermosetting resin to form the final product which is cut into suitable sizes for easyhandling and installation. Other products such as wired blanket, pipe cover or faced products are producedby secondary process

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 40 working days can be served.

- Q: Is it possible to use aluminum foil with a reflective side for baking purposes? If yes, what is the method of using it?

- <p>Yes, aluminum foil facing can be used for baking. To use it, place the foil shiny side up on the baking sheet to reflect heat and promote even cooking. It can also be used to cover the food to prevent over-browning or to create a steaming effect, which can help in cooking delicate items. Remember to use it carefully as it can get very hot and can cause burns. Always handle with oven mitts and avoid direct contact with the foil.</p>

- Q: This question asks for methods to clean the surface of aluminum foil facing, which is a type of material used in construction.

- <p>To clean aluminum foil facing, start by removing any loose dirt or debris with a soft brush. Then, use a mild detergent mixed with warm water and a soft cloth to gently wipe the surface. Avoid using abrasive cleaners or scrubbers, as they can damage the foil. For stubborn stains, a mixture of equal parts white vinegar and water can be applied with a cloth, followed by rinsing with clean water. Always let the surface dry completely to prevent water spots or damage.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: What are the potential health risks associated with cooking food using aluminum foil?

- <p>Cooking with aluminum foil can potentially lead to the leaching of aluminum into the food, which may have health implications. While the body naturally eliminates small amounts of aluminum, excessive intake can be harmful. Aluminum has been linked to neurological disorders, including Alzheimer's disease, although the connection is not definitively proven. It's also important to note that the amount of aluminum that leaches into food during cooking is generally considered to be low. However, for those concerned about aluminum exposure, it's advisable to minimize the use of aluminum foil in cooking, especially for acidic foods which can increase the rate of aluminum leaching.</p>

- Q: What are the most effective ways to clean surfaces that have aluminum foil applied to them?

- <p>The best cleaning methods for aluminum foil facing involve gentle cleaning to avoid damaging the foil. Use a soft cloth or sponge with warm water and mild dish soap to wipe the surface. Avoid abrasive cleaners or scrubbing, as this can scratch or tear the foil. For stubborn stains, a mixture of baking soda and water can be applied as a paste and gently rubbed with a soft cloth. Always rinse thoroughly and dry the surface to prevent water spots and maintain the integrity of the aluminum foil.</p>

- Q: Is it possible to use aluminum foil facing to create a container for holding liquids or powders?

- <p>While aluminum foil facing can be used to create a temporary or makeshift container for storing liquids or powders, it is not recommended for long-term storage due to potential permeability issues. Aluminum foil is not watertight and can allow moisture and air to pass through, which may affect the quality of the stored substances. For liquids, it can also be prone to leaks. It is better to use containers specifically designed for the purpose, made from materials that are impermeable and suitable for the substances being stored.</p>

- Q: This question asks for a comparison of the benefits and drawbacks associated with the use of aluminum foil facing in various applications.

- <p>Aluminum foil facing offers several advantages, including excellent heat reflection, which can improve insulation and energy efficiency in buildings. It also provides a moisture barrier, which can protect against water damage and mold growth. Additionally, aluminum foil facing is lightweight, easy to install, and resistant to corrosion. However, there are disadvantages such as its limited strength and durability compared to other materials, making it prone to punctures and tears. It can also be less aesthetically pleasing and may require additional protective layers for long-term use. Furthermore, improper disposal can contribute to environmental concerns due to its non-biodegradable nature.</p>

- Q: Explain the distinction between aluminum foil insulation with and without a vapor barrier.

- <p>Aluminum foil insulation with a vapor barrier is designed to prevent moisture from passing through, which is crucial in humid environments to prevent condensation and mold growth. The vapor barrier is a layer that acts as a moisture control, enhancing the insulation's effectiveness. On the other hand, aluminum foil without a vapor barrier does not have this moisture-resistant layer, making it less effective in controlling moisture and potentially leading to condensation issues. The presence of a vapor barrier can also impact the thermal performance and energy efficiency of the insulation.</p>

- Q: Explain the differences between aluminum foil facing and plastic wrap when it comes to storing food.

- <p>Aluminum foil facing and plastic wrap are both used for food storage, but they have distinct properties. Aluminum foil facing is a moisture-resistant barrier that reflects heat, making it ideal for cooking and reheating food in the oven or microwave. It's also good for sealing in freshness and preventing freezer burn. Plastic wrap, on the other hand, is a clingy film that tightly seals around food to keep it fresh. It's transparent, allowing you to see the contents, and is useful for covering dishes and bowls. However, it's not heat resistant and can melt or release harmful chemicals when heated, so it's not suitable for cooking or reheating food.</p>

- Q: Is it safe to use aluminum foil facing inside a pressure cooker and does it pose any risks?

- <p>Using aluminum foil facing in a pressure cooker is generally safe and is commonly used to prevent food from sticking to the pot. However, it's important to ensure that the foil does not block the pressure release valve or the vent, as this could lead to a buildup of pressure and potentially cause the cooker to malfunction. Always follow the manufacturer's guidelines for your specific pressure cooker model to avoid any safety issues.</p>

Send your message to us

Aluminum Foil Facing Rock Wool Board for Wall Partition of Highly Valued Quality

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 700 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords