Aluminum Foil Facing LDPE Coated Aluminum Foil for Heat Seal Laminating Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 inch

- Supply Capability:

- 300000 inch/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum foil facing insulation for Roofing Insulation

1. Aluminum Foil Facing Description:

The production technologies and products performance of aluminum foil facing have been up to international advanced level. The aluminum foil facing products are mainly used for HVAC system, refrigerators, building thermal aluminum foil facing insulation and laminated with glass wool and rock wool to increase the insulation function.

• FSK aluminum foil facing is mainly used for duct wrap in HVAC system and other fields, such as vapor barrier etc., and suitable for off-line lamination of glass wool or rock wool. By special processing, the facing will have excellent flame retardant property.

• Heat-sealing aluminum foil facing is used for duct wrap without applying extra adhesive and suitable for online lamination of glass wool and rock wool.

• The PSK aluminum foil facing, whose structure is white polypropylene/ fiberglass scrim/ kraft is mainly used for metal building insulation and suitable for the insulation of ware-house, factory, supermarket, office and so on.

• Double sided aluminum foil facing vapor barrier, whose structure is aluminum foil/ high strength kraft /fiberglass scrim /aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

2.Main Features of the Aluminum foil facing:

• Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• environmentally friendly,no smell and not-toxic;

• Smooth and clear surface;

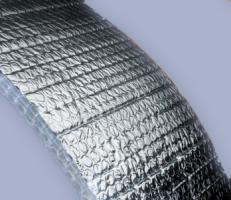

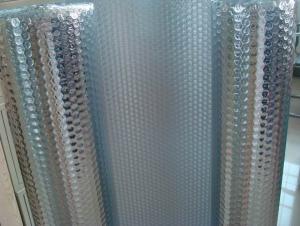

3.Aluminum Foil Facing Images

4.Aluminum Foil Facing Specification

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 88 | ASTM D646 |

Tensile strength: M. D. X. D. | N/25mm | 110 50 | ASTM D828 |

Burst strength | N | 30 | ASTM D774 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -29°C 66°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permeance | ng/N.s | 1.15 | ASTM E-96 |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

1. How about your company?

A world class manufacturer & supplier of aluminum foil facing and is one of the large-scale professional investment aluminum foil facing bases in China. Annually more than 1000 containers of aluminum foil facing are exported to markets in Europe, America and Japan.

2. What is the storage condition?

The Aluminum foil facing should be stored at room temperature and kept from wet and heat source.

3, How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. How long can we receive the product after purchase?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for methods to prevent aluminum from aluminum foil leaching into food.

- <p>To avoid aluminum from aluminum foil leaching into your food, use the foil sparingly and avoid wrapping food directly in it. Opt for heavy-duty aluminum foil, which is less likely to tear and expose food to aluminum. When cooking acidic or salty foods, consider using parchment paper or silicone baking mats as alternatives. Additionally, avoid using aluminum foil at high temperatures, as this can increase the risk of aluminum transfer. Finally, store food in glass or stainless steel containers instead of aluminum foil to minimize exposure.</p>

- Q: This question asks about potential health or safety risks associated with the use of non-stick coatings on food covers or containers.

- <p>Non-stick coatings on food covers or containers are generally safe when used as directed. However, there are some concerns. High heat can cause these coatings to release potentially harmful fumes or chemicals, such as perfluorooctanoic acid (PFOA), which has been linked to health issues. It's important to avoid overheating non-stick items and to not use them in the oven or broiler. Always follow the manufacturer's guidelines for safe use and cleaning. If the coating is scratched or peeling, it's best to replace the item to prevent ingestion of the coating particles.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a sandwich?

- <p>Using aluminum foil facing to make a sandwich is not recommended. Aluminum foil is not designed for direct food contact, especially when heated, as it can leach aluminum into the food, which is potentially harmful. Instead, use materials specifically designed for food contact, such as wax paper, parchment paper, or plastic wrap, which are safe for contact with food and can withstand the temperatures involved in making a sandwich.</p>

- Q: Is it safe to use aluminum foil with a nonstick coating for cooking or baking purposes?

- <p>Using nonstick-coated aluminum foil for cooking or baking is generally safe, but it's important to follow the manufacturer's guidelines regarding temperature limits. Nonstick coatings are designed to withstand high temperatures, but excessive heat can cause them to break down or release harmful fumes. Always ensure the foil is placed in a way that the nonstick side does not come into direct contact with the heat source to prevent damage to the coating. Additionally, avoid using sharp or abrasive objects on the nonstick surface to maintain its integrity.</p>

- Q: What are the primary applications or purposes of aluminum foil facing in various industries or everyday life?

- <p>Aluminum foil facing is primarily used for its heat reflective properties, making it ideal for insulation in construction and roofing. It also serves as a moisture barrier and vapor barrier in walls and ceilings, helping to prevent mold and mildew. In the HVAC industry, it's used for duct insulation, enhancing energy efficiency. Additionally, it's utilized in packaging for food and pharmaceuticals to protect contents from light, air, and moisture, thus preserving freshness and quality.</p>

- Q: What are the most suitable materials for creating aluminum foil facing?

- <p>The best materials for making aluminum foil facing are typically aluminum alloys, specifically 1100, 3003, or 8011 series alloys. These alloys offer excellent formability, corrosion resistance, and reflectivity, which are crucial for applications like insulation, construction, and heat management. Additionally, the facing material often includes a layer of polyester or polyethylene film to enhance durability and prevent tearing. The choice of material can also depend on specific requirements such as temperature resistance, UV resistance, and environmental conditions.</p>

- Q: Is it safe to use aluminum foil facing material to cover food when microwaving?

- <p>No, it is not recommended to use aluminum foil facing to wrap food in the microwave. Aluminum foil can cause sparks and potentially start a fire due to the metal's conductive properties. It can also reflect microwaves, damaging the microwave's interior and potentially the appliance itself. Always use microwave-safe materials, such as microwave covers or wax paper, to cover food during microwaving.</p>

- Q: What are the particular criteria or considerations when choosing aluminum foil facing materials?

- <p>When selecting aluminum foil facing, specific requirements include the foil's thickness, which affects durability and insulation properties; surface finish, which can impact heat reflection and aesthetics; and the type of adhesive used for bonding, which should be resistant to heat and moisture. Additionally, the foil should have good barrier properties to prevent moisture and air infiltration, and it should be compatible with the substrate materials to ensure a strong bond. Compliance with safety and environmental standards is also crucial.</p>

- Q: The user wants to know if they can reuse their old aluminum foil facing to create a new one if it gets damaged.

- <p>Yes, you can use your old aluminum foil facing to make a new one if it gets damaged. Simply clean the old foil facing thoroughly, ensuring all adhesive residue is removed. Then, cut a new piece of aluminum foil to the appropriate size and shape. Apply a thin layer of adhesive, such as construction adhesive or double-sided tape, to the back of the new foil. Press it firmly onto the old facing, ensuring a smooth and secure bond. Allow it to dry according to the adhesive's instructions before using. This can be a cost-effective way to extend the life of your foil facing.</p>

- Q: Is it possible to use aluminum foil facing in the process of making desserts or cakes?

- <p>Yes, you can use aluminum foil facing to make desserts or cakes. It is commonly used for lining baking pans to prevent sticking and to ensure easy removal of the baked goods. Aluminum foil is heat resistant and can be used in the oven, but it's important to avoid direct contact with the heating elements to prevent burning. For best results, use heavy-duty aluminum foil and ensure it covers the bottom and sides of the pan completely.</p>

Send your message to us

Aluminum Foil Facing LDPE Coated Aluminum Foil for Heat Seal Laminating Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 inch

- Supply Capability:

- 300000 inch/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords