Aluminum Foil Facing Aluminum Foil / LDPE; Aluminum Foil / PET; Aluminum Foil / PET / LDPE; 12mic MPET/20mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

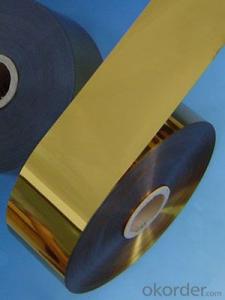

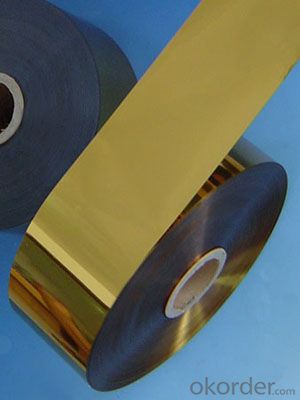

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for a method to determine the thickness of an aluminum foil sheet.

- <p>To measure the thickness of an aluminum foil sheet, you can use a digital caliper or a micrometer. Place the foil between the jaws of the caliper and take the measurement. If you don't have these tools, you can use the 'multiple fold' method: fold the foil in half repeatedly and measure the total thickness after several folds, then divide by the number of layers to estimate the single layer thickness. For a more precise measurement, especially for thinner foils, consider using a thickness gauge designed for measuring thin materials.</p>

- Q: This question asks about the proper way to store aluminum foil to keep it facing the right way for easy use.

- <p>To store aluminum foil facing the right way, first use up one side completely. Then, fold the remaining foil in half with the shiny side facing out. Place the folded foil back into the box or container, shiny side up. When you need to use it next, the shiny side will be facing you, making it easy to tear off. To keep it flat and wrinkle-free, you can place a piece of cardboard inside the box, or roll it around a clean, empty paper towel tube.</p>

- Q: Is it safe to use aluminum foil facing to wrap food for the purpose of freezing?

- <p>Yes, you can use aluminum foil facing to wrap food for freezing. Aluminum foil is a good conductor of heat and can help food freeze quickly, preserving its freshness. It also protects the food from freezer burn and helps maintain its moisture. However, ensure that the foil is food-grade and avoid using it in direct contact with acidic or high-sodium foods, as these can cause a reaction with the aluminum. For best results, wrap the food tightly and securely to prevent air exposure, which can lead to freezer burn.</p>

- Q: Is it possible to use aluminum foil facing more than once?

- <p>Yes, you can reuse aluminum foil facing for multiple uses. However, it's important to note that the effectiveness of the foil decreases with each use due to wear and tear. It may become less reflective and less effective at insulating heat. Make sure to clean it thoroughly after each use and inspect for any damage or tears before reusing. For best results, limit the number of times you reuse the foil facing to maintain its performance.</p>

- Q: This question is incomplete, but it seems to be asking about special cleaning methods required for a specific situation or item.

- <p>Special cleaning methods can vary greatly depending on the context. For instance, cleaning electronic devices requires anti-static wipes, while cleaning antiques may need gentle, non-abrasive cleaners. In the case of medical equipment, sterilization is crucial. For specific items like carpets, steam cleaning might be necessary. Always refer to manufacturer's instructions or professional guidelines for the best cleaning practices.</p>

- Q: This question asks for signs or methods to identify if the aluminum foil facing of a product, such as insulation or a jacket, is damaged or defective.

- <p>To determine if your aluminum foil facing is damaged or defective, look for visible signs such as tears, punctures, or holes. Check for any discoloration or rust, which could indicate corrosion. The foil should be smooth and uniform; any irregularities or bubbling might suggest a defect. Additionally, test the integrity by gently pulling or pressing the foil鈥攊f it easily tears or crumples, it may be compromised. For insulation, a damaged foil facing can lead to reduced effectiveness in heat or cold retention, so also consider the performance of the item.</p>

- Q: Can aluminum foil be utilized as a facing material for cooking in a microwave oven?

- <p>Aluminum foil facing should not be used for microwave cooking. Microwaves can cause the foil to heat up and potentially create sparks or even start a fire. It can also reflect microwaves, damaging the microwave's interior and potentially the oven itself. Always use microwave-safe materials, such as glass or microwave-safe plastic containers, for cooking in a microwave.</p>

- Q: This question asks for methods to prevent aluminum foil from sticking to itself when stored or used.

- <p>To prevent aluminum foil from sticking to itself, you can try several methods. First, store it with a sheet of wax or parchment paper between each layer to create a barrier. Second, lightly coat the foil with cooking spray or oil before stacking. Alternatively, use a paper towel as a separator. When using, dampen the foil slightly with water to reduce the sticking. Additionally, you can purchase non-stick aluminum foil or use plastic wrap as a substitute. These methods will help maintain the separation and functionality of aluminum foil.</p>

- Q: Is it safe or practical to use aluminum foil facing as a material for making soup?

- <p>No, it is not advisable to use aluminum foil facing for making soup. Aluminum foil is not designed for direct contact with food, especially when heated, as it can potentially leach aluminum into the food. Additionally, aluminum foil is not a suitable material for cooking vessels as it can tear or puncture easily, leading to safety hazards. Instead, use materials specifically designed for cooking, such as stainless steel, ceramic, or glass cookware, which are safe and non-reactive with food.</p>

- Q: Is it possible to use aluminum foil facing as a substitute for a roasting pan?

- <p>While aluminum foil facing can be used in some baking situations, it is not recommended to use it as a direct substitute for a roasting pan. Aluminum foil is not designed to withstand the high temperatures of a roasting process and can melt or warp, leading to uneven cooking and potential safety hazards. A proper roasting pan is made to handle high heat and distribute it evenly, ensuring that your food cooks properly. For best results and safety, use a designated roasting pan or a baking sheet with a higher heat tolerance.</p>

Send your message to us

Aluminum Foil Facing Aluminum Foil / LDPE; Aluminum Foil / PET; Aluminum Foil / PET / LDPE; 12mic MPET/20mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords