Aluminum Foil Facing DFC-1001A Fiberglass Wool Roll Insulation Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Aluminum Foil Facing DFC-100A

Aluminum foil: 7u / Tri-way fiberglass scrim: 8x12/100mm / Polyethylene /

Kraft paper: 50gsm / Polyethylene / Aluminum foil: 7u

TYPICAL PHYSICAL PROPERTIES:

PROPERTIES | UNIT | VALUE | TEST METHOD | ||||

Basic weight | gsm | 115 | ASTM D646 | ||||

Tensile strength: M. D. X. D. | N/25mm | 100 75 | ASTM C1136 | ||||

Burst strength | N | 35 | ASTM D774 | ||||

Reflectivity of foil surface | % | 95 | ---------- | ||||

Temp. Resistance | -29°C +66°C | No change keep soft | ASTM C1263 | ||||

Water Soak Test | 24hrs | No delamination | ---------- |

Width: 1.0 m, 1.2m, 1.25m, 1.3m

Length: 100m, 200m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

Remarks:

1.The data above are typical results and subject to change without notice.

2.Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3.The products should be stored at room temperature and kept from wet and heat source.

4.It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5.The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

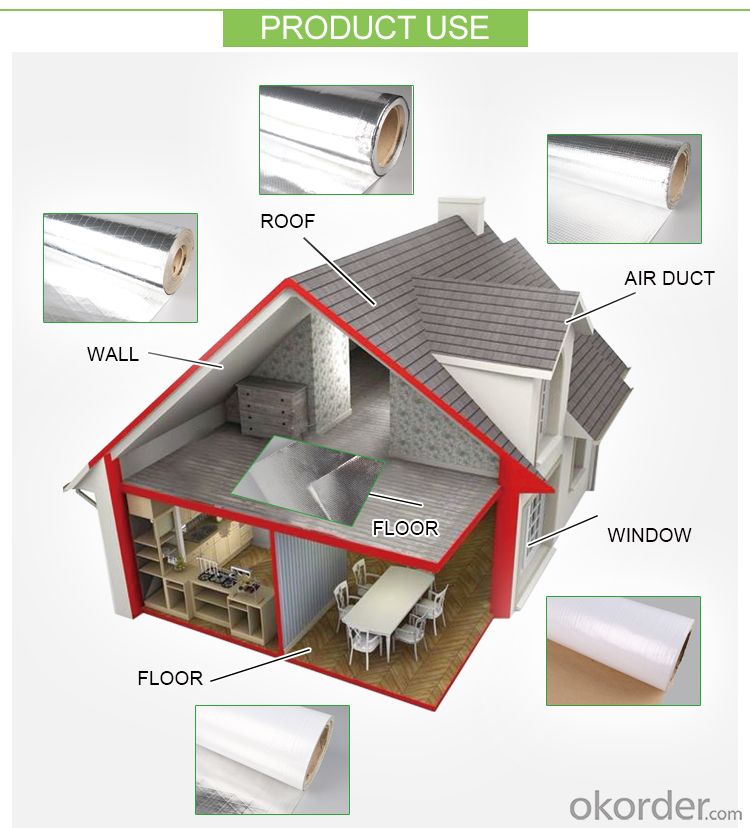

2. Application of Aluminum Foil Facing DFC-100A

The product can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

3. Packaging & Delivery of Aluminum Foil Facing DFC-100A

Depends on the clients' requirements and the production conditions.

- Q: This question asks for various purposes that aluminum foil facing can be used for, other than its conventional use.

- <p>Aluminum foil facing has several alternative uses. It can be used as a reflective surface to enhance the heat distribution in grilling or baking. It can also serve as a protective barrier in gardening to deter pests or as a makeshift sled for sliding on snow. Additionally, it can be used to clean stubborn stains or as a shield to protect surfaces from paint splatters during home improvement projects. Some people even use it for crafting or DIY projects due to its malleability and reflective properties.</p>

- Q: Describe the most effective method for folding aluminum foil edges to seal food packaging.

- <p>The best way to fold aluminum foil facing for food packaging involves a few simple steps. Start by placing the food in the center of the foil. Bring two opposite edges of the foil together over the food, ensuring they overlap slightly. Fold one edge over the other, creating a seam. Press down firmly to seal. Repeat this process with the remaining two edges, ensuring all edges are sealed tightly. For added security, you can fold the edges inward to create a double seam. This method prevents leakage and keeps the food fresh and protected during cooking or storage.</p>

- Q: What distinguishes aluminum foil facing from other types of foils?

- <p>Aluminum foil facing is characterized by its aluminum layer, which provides excellent heat and light reflection, making it ideal for insulation and cooking applications. It's also resistant to corrosion and has a shiny finish. In contrast, other types of foils like Mylar (polyester) are more flexible and tear-resistant, used in various industrial applications. Copper foil is used for electronics due to its high conductivity, while gold foil is valued for its decorative properties. Each type of foil has unique properties that make it suitable for specific uses, with aluminum foil facing being particularly known for its thermal and reflective qualities.</p>

- Q: What are the safety regulations or guidelines that aluminum foil facing must adhere to?

- <p>Safety standards for aluminum foil facing are crucial to ensure the product's safety and effectiveness. These standards typically include requirements for material composition, thickness, and bonding strength to ensure the foil's durability and resistance to tearing. Additionally, there are guidelines for the foil's reflectivity and heat resistance, which are important for its performance in various applications. Compliance with these standards is often verified through testing and certification processes, ensuring that aluminum foil facing products meet the necessary quality and safety benchmarks before they reach the market.</p>

- Q: This question asks for a method to clean aluminum foil after cooking to get rid of excess oil.

- <p>To remove excess oil from aluminum foil after cooking, first let the foil cool down to avoid burns. Then, you can use a paper towel or a clean cloth to gently wipe away the oil. For stubborn oil, you can wash the foil with warm soapy water. If you're reusing the foil, make sure it's thoroughly dried before storing to prevent any potential for bacterial growth. Always remember to handle aluminum foil with care as it can be sharp and may tear easily.</p>

- Q: Is it possible to use aluminum foil with a facing layer to create a sandwich?

- <p>Using aluminum foil facing to make a sandwich is not recommended. Aluminum foil is not designed for direct food contact, especially when heated, as it can leach aluminum into the food, which is potentially harmful. Instead, use materials specifically designed for food contact, such as wax paper, parchment paper, or plastic wrap, which are safe for contact with food and can withstand the temperatures involved in making a sandwich.</p>

- Q: Is it safe to reuse aluminum foil for food packaging purposes?

- <p>While it may be tempting to reuse aluminum foil for food packaging, it is generally not recommended due to hygiene and safety concerns. Recycled aluminum foil can harbor bacteria and other contaminants, which can be transferred to the food. Additionally, the foil can tear easily when reused, leading to potential food waste. It's best to use fresh aluminum foil each time to ensure food safety and maintain the integrity of your packaging.</p>

- Q: What are the chemical characteristics of the side of aluminum foil that faces outwards?

- <p>The chemical properties of the aluminum foil facing outward are primarily determined by its elemental composition, which is aluminum (Al). Aluminum is a lightweight, soft, and malleable metal with a silvery-white appearance. It is highly reactive and readily forms a thin, protective oxide layer (aluminum oxide) when exposed to air, which prevents further oxidation. This oxide layer is what gives aluminum foil its resistance to corrosion and its shiny appearance. Aluminum is also a good conductor of heat and electricity. The facing side of the aluminum foil may have slight differences in properties due to the manufacturing process, but fundamentally, it remains chemically similar to the rest of the aluminum foil.</p>

- Q: Is it safe to use aluminum foil as a liner in a slow cooker, and are there any potential risks or benefits?

- <p>Using aluminum foil as a facing in a slow cooker is generally safe. It can help with easy cleanup and may distribute heat evenly. However, it's important to ensure that the foil doesn't touch the heating element, as this can cause damage to both the foil and the slow cooker. Additionally, while aluminum foil is non-toxic and generally safe, there are concerns about potential leaching of aluminum into food, especially with acidic foods. For health-conscious individuals, using a slow cooker liner made from materials like silicone or stainless steel might be a better alternative.</p>

- Q: This question asks about the various types of aluminum foil facing used in construction and insulation materials.

- <p>Aluminum foil facing is used in various applications, including insulation and construction materials. The different types include: 1) Plain Foil Facing, which is a smooth, uncoated aluminum foil; 2) Coated Foil Facing, which has a protective coating applied to one or both sides; 3) Laminated Foil Facing, where aluminum foil is bonded to other materials like polyester or polyethylene; 4) Embossed Foil Facing, featuring a pattern or texture on the surface for added strength or aesthetic purposes; and 5) Reinforced Foil Facing, which incorporates additional materials to enhance durability and tear resistance.</p>

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$ 0.3 billion |

| Main Markets | 0.00% Mid East 0.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe South east asia;North America,South America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Foil Facing DFC-1001A Fiberglass Wool Roll Insulation Blanket

- Loading Port:

- China main port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords