Aluminum Foil Facing Metalized PET/LDPE; 12mic MPET + 15mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Structure

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

● Aluminum foil – LDPE

● Aluminum foil- PET- LDPE

● Clear Transparent PET-Aluminum foil – LDPE

● Aluminum foil-Metallized PET- LDPE

● Metallized PET- LDPE

Product Application

Widely used for laminating with EPE insulation, Bubble insulation, woven fabric insulation, etc

Product Advantage

Light weight

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• High reflective insulation

• Heat resistant, water proof, stable at high temperature;

• Environmentally friendly, no smell and not-toxic;

• Smooth and clear surface;

Product Packing

1. Waterproof paper then PVC shrinking Film

2. Kraft paper only

3. Woven cloth

4. Kraft paper or Water Proof Film then Metal/wooden pallet

5. (Also as your request. )

Product Remarks

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

Product Data Sheet

PROPERTIES | UNIT | VALUE | TEST METHOD |

Basic weight | gsm | 33.5 | ASTM D646 |

Thickness | mic | 23.2 | ASTM D646 |

Tensile strength: M. D. X. D. | N/15mm | 13.5 13.5 | ASTM D882 |

Delaminating Values | N/15mm | 1.5 | ASTM D904 |

Reflectivity of foil surface | % | 95 | ---------- |

Temp. Resistance | -40°C 130°C | No Delamination No Delamination | ASTM C1263 |

Water vapor permanence | ng/N.s | 1.15 | ASTM E-96 |

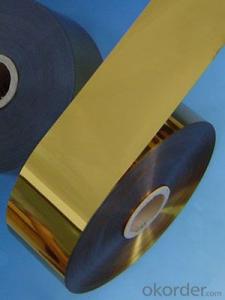

Product Picture

FAQ

1. What is the product keeping conditions?

The Aluminum Foil Facing should be stored at room temperature and kept from wet and heat source.

2. What is the guarantee years of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. What is the delivery time of the order?

In the purchase of product within four working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: This question asks for methods to clean aluminum foil facing that has old food stains on it after cooking.

- <p>To remove old food stains from aluminum foil facing, start by scraping off any loose debris with a spatula or scraper. Then, soak the stained area in warm soapy water for about 15 minutes. Use a soft cloth or sponge to gently scrub the stains. For stubborn stains, make a paste of baking soda and water, apply it to the stain, and let it sit for a few hours before scrubbing. Rinse thoroughly with water. If stains persist, consider using a non-abrasive cleaner specifically designed for aluminum surfaces. Always test any cleaning solution on a small, inconspicuous area first to ensure it doesn't damage the surface.</p>

- Q: Is it possible to use aluminum foil with a reflective side to wrap sandwiches?

- <p>Yes, you can use aluminum foil facing to make sandwiches. The reflective side of aluminum foil is food-safe and can be used to wrap sandwiches for storage or transportation. It helps to keep the sandwich fresh and prevents it from drying out. However, it's important to ensure the foil is clean and free from any sharp edges that might tear the bread or packaging. Additionally, it's best to avoid using foil with non-stick coatings on the inside when in contact with food.</p>

- Q: Is it possible to utilize a sheet of aluminum foil as a liner for a baking pan?

- <p>Yes, you can use a sheet of aluminum foil as a baking pan liner. It helps prevent food from sticking to the pan and makes cleanup easier. Ensure the foil covers the bottom and sides of the pan, and use enough to fold over the edges for easy removal of baked goods. However, avoid using foil for very high-temperature baking or broiling as it can melt or burn.</p>

- Q: Is it safe to use aluminum foil as a cooking surface? If yes, what kinds of foods are suitable for cooking with aluminum foil?

- <p>Yes, aluminum foil can be used for cooking, but it's important to use it safely. It's suitable for wrapping foods like fish, meats, and vegetables to retain moisture and flavor. It's also used for making packets for steaming or baking, and for lining baking sheets to prevent sticking. However, avoid using it with acidic foods or at high temperatures as it can react with the food or release aluminum into the food. Always use heavy-duty aluminum foil for cooking to ensure it can withstand the heat.</p>

- Q: Is it safe to use aluminum foil facing on lunch boxes for making sandwiches or wraps?

- <p>Yes, you can use aluminum foil facing to make sandwiches or wraps for lunch boxes. Aluminum foil is a common material used for food packaging due to its ability to keep food fresh and protected. It is non-toxic and does not react with most foods, making it safe for use in lunch boxes. However, it's important to ensure that the foil does not tear or come into direct contact with acidic foods, as this could potentially lead to the leaching of aluminum. Always handle food with clean hands or utensils to maintain hygiene.</p>

- Q: Is it safe to use aluminum foil with a reflective side for storing leftover food?

- <p>Yes, aluminum foil facing can be used for storing leftovers. Aluminum foil is a versatile food storage material that provides a barrier against air, moisture, and bacteria, helping to keep leftovers fresh. The reflective side of the foil is often used because it is thicker and more resistant to tearing, which can be beneficial for containing liquids and ensuring the food is well-sealed. However, it's important to ensure that the foil does not come into direct contact with acidic or highly salty foods, as this can lead to a reaction that may affect the taste or safety of the food.</p>

- Q: Is it safe to use the same piece of aluminum foil repeatedly before disposal?

- <p>Reusing aluminum foil is generally not recommended due to hygiene and food safety concerns. Each time you use foil, it can pick up bacteria from food and surfaces, which can multiply with subsequent uses. Additionally, the foil can tear or become thin, potentially allowing harmful substances to leach into your food. For safety, it's best to use a fresh piece of aluminum foil for each use.</p>

- Q: This question asks for a comparison between aluminum foil facing and other types of metal foil facing, focusing on their differences.

- <p>Aluminum foil facing is distinct from other metal foil facings due to its unique properties. It is lightweight, highly reflective, and offers excellent heat resistance. It's also non-toxic and has good barrier properties against oxygen and moisture, making it ideal for food packaging and insulation. Other metal foils, such as copper or stainless steel, may have different thermal or electrical conductivity properties, and are often heavier and less flexible. Copper, for instance, has higher electrical conductivity but is less common in foil applications due to cost and weight. Stainless steel foils are more durable and corrosion-resistant but are not as reflective or lightweight as aluminum. Each type of metal foil has specific applications based on its unique characteristics.</p>

- Q: Explain the various applications of aluminum foil facing in different contexts.

- <p>Aluminum foil facing can be used in various ways depending on the application. In construction, it serves as a vapor barrier to prevent moisture from affecting the insulation. In packaging, it's used for food preservation, providing a barrier against air and light, which helps to keep food fresh. In the automotive industry, it's used for heat reflection and insulation in car engines. It's also used in the manufacturing of reflective materials and in art for creating unique textures and effects. Additionally, aluminum foil facing is utilized in the aerospace industry for heat shielding and in the medical field for sterilization purposes. Each application leverages the properties of aluminum foil, such as its light weight, durability, and heat resistance.</p>

- Q: Is it possible to use aluminum foil facing in the process of making desserts or cakes?

- <p>Yes, you can use aluminum foil facing to make desserts or cakes. It is commonly used for lining baking pans to prevent sticking and to ensure easy removal of the baked goods. Aluminum foil is heat resistant and can be used in the oven, but it's important to avoid direct contact with the heating elements to prevent burning. For best results, use heavy-duty aluminum foil and ensure it covers the bottom and sides of the pan completely.</p>

Send your message to us

Aluminum Foil Facing Metalized PET/LDPE; 12mic MPET + 15mic Polyester

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords