Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

EQUIPMENT | Double coating double baking; |

CAPACITY | 5000Mt/week |

SIZE | Thickness 0.18mm—2mm, width 40mm—1250mm |

PAINT THICKNESS | Top:18--25um, back:5-7um |

COIL WGT | 3Mt - 8Mt |

COIL ID | φ508mm,φ610mm |

SURFACE PAINT | EP, PE, HDP, SMP, PVDF |

COLOR SERIES | RAL color number series |

2. Application of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

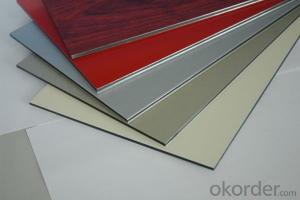

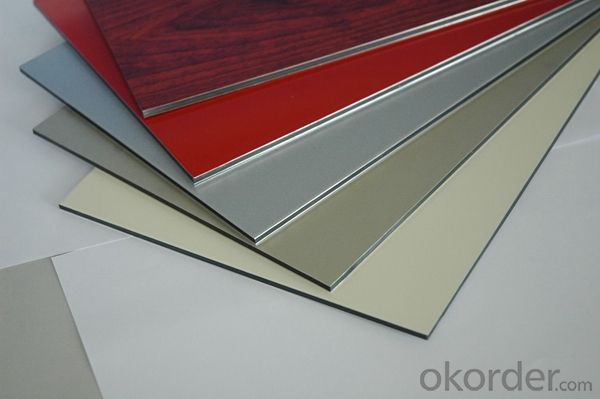

5. Image of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

6. Package and shipping of Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: Are aluminum sheets suitable for cladding?

- Yes, aluminum sheets are suitable for cladding due to their durability, lightweight nature, and corrosion resistance. Additionally, aluminum offers versatility in terms of design options and ease of installation, making it a popular choice for cladding applications in various industries.

- Q: Can 101 aluminum sheets be anodized for medical equipment applications?

- Yes, 101 aluminum sheets can be anodized for medical equipment applications. Anodizing is a process that enhances the corrosion resistance and durability of aluminum, making it suitable for various industries, including medical equipment.

- Q: What are the primary components that make up aluminum sheets?

- <p>Aluminum sheets are primarily composed of aluminum, which is a lightweight and malleable metal. They are made from pure aluminum or aluminum alloys, which may include small percentages of other elements to enhance specific properties such as strength, corrosion resistance, or workability. Common alloying elements include copper, magnesium, manganese, silicon, and zinc. The exact composition varies depending on the specific grade of aluminum and its intended use. Pure aluminum is soft and not commonly used for sheets; instead, alloys are preferred for their improved strength and durability.</p>

- Q: aluminum is 2.82x10^-8 ohm-m

- Aluminum with the same resistance as 50 meters of copper. (Resistance) = (Resistivity)(Length/Area) So if the resistivity changes by (2.82/1.72), then the length changes by (1.72/2.82). So the length of aluminum would be 50m(1.72/2.82) Length of aluminum would be 30.5 meters

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The thickness tolerance of aluminum sheet plays a significant role in its usability. A narrow thickness tolerance ensures uniformity and precision in the sheet's dimensions, allowing for consistent performance and ease of fabrication. It enables seamless integration into various applications, including construction, automotive, aerospace, and manufacturing industries. On the other hand, a wider thickness tolerance can limit its usability as it may result in irregularities, difficulty in fitting, and potential performance issues. Therefore, a tight thickness tolerance is crucial for ensuring optimal functionality and versatility of aluminum sheets.

- Q: Are aluminum sheets suitable for chemical storage containers?

- Aluminum sheets are generally not suitable for chemical storage containers. While aluminum is known for its corrosion resistance, it can still react with certain chemicals, leading to degradation of the container and potential contamination of the stored substance. Additionally, aluminum is a relatively soft metal and may not provide adequate strength and durability for long-term storage of hazardous chemicals. It is advisable to use materials specifically designed for chemical storage, such as high-density polyethylene (HDPE), polypropylene (PP), or stainless steel, which offer superior chemical resistance and structural integrity.

- Q: What is the typical fatigue strength of aluminum sheets?

- The typical fatigue strength of aluminum sheets can vary depending on several factors such as alloy composition, thickness, manufacturing process, and surface treatment. However, in general, aluminum sheets have a relatively high fatigue strength compared to other materials. Aluminum alloys, especially those used in aerospace and automotive applications, are known for their excellent fatigue resistance. The fatigue strength of aluminum sheets is typically expressed in terms of the stress level (in MPa) at which failure occurs after a certain number of cycles. For aluminum alloys commonly used in structural applications, the fatigue strength can range from around 70 MPa to 150 MPa, depending on the specific alloy and thickness. However, it is important to note that this is a general range, and there can be significant variations based on the aforementioned factors. It is worth mentioning that the fatigue strength of aluminum sheets can be significantly enhanced through various techniques such as heat treatment, alloying, and surface treatments like shot peening or anodizing. These processes can increase the fatigue life and improve the overall performance of aluminum sheets in cyclic loading conditions. In conclusion, the typical fatigue strength of aluminum sheets can be considered relatively high compared to other materials, but it can vary depending on several factors. Proper material selection, along with appropriate processing and surface treatments, can significantly improve the fatigue performance of aluminum sheets.

- Q: What is the weight per square foot of 101 aluminum sheets?

- The weight per square foot of 101 aluminum sheets can vary depending on the thickness of the sheets. Generally, the weight of aluminum is measured in pounds per square foot (lbs/ft²). To determine the exact weight per square foot of 101 aluminum sheets, you would need to know the thickness of each sheet. Once you have the thickness, you can use the density of aluminum, which is approximately 0.098 pounds per cubic inch (lbs/in³), to calculate the weight per square foot.

- Q: What is the fatigue strength of aluminum sheets?

- The fatigue strength of aluminum sheets varies depending on several factors such as the alloy composition, thickness, surface condition, and the specific loading conditions. Aluminum alloys generally exhibit good fatigue strength, particularly when compared to other metals. The fatigue strength of aluminum sheets is typically determined through fatigue testing, where specimens are subjected to cyclic loading until failure. The S-N curve, which represents the relationship between the number of cycles to failure (N) and the applied stress amplitude (S), is used to characterize the fatigue behavior of aluminum sheets. Aluminum alloys, such as 2024-T3 and 6061-T6, commonly used in aerospace and automotive industries, have high fatigue strengths and can withstand millions of cycles at certain stress levels. For example, 2024-T3 aluminum alloy has a fatigue strength of approximately 105 MPa (15,000 psi) at 10^6 cycles, whereas 6061-T6 aluminum alloy has a fatigue strength of around 96 MPa (14,000 psi) at the same number of cycles. It is important to note that the fatigue strength of aluminum sheets can be influenced by various factors, such as the presence of surface defects, corrosion, temperature, and loading frequency. Proper surface preparation, including smoothing and removing sharp edges, can increase the fatigue strength of aluminum sheets. Additionally, the use of proper stress relief treatments and design considerations, such as avoiding stress concentrations and optimizing joint design, can also improve the fatigue performance of aluminum sheets. Overall, the fatigue strength of aluminum sheets is generally considered to be good, but it is important to consider the specific alloy, thickness, surface condition, and loading conditions to accurately determine and optimize the fatigue performance in practical applications.

Send your message to us

Color Coated Aluminium Sheet Plate AA3003 for Building Outside Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords