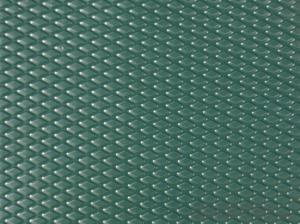

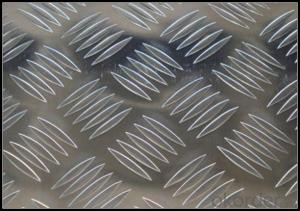

Aluminum Sheets in Kansas - Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

Description

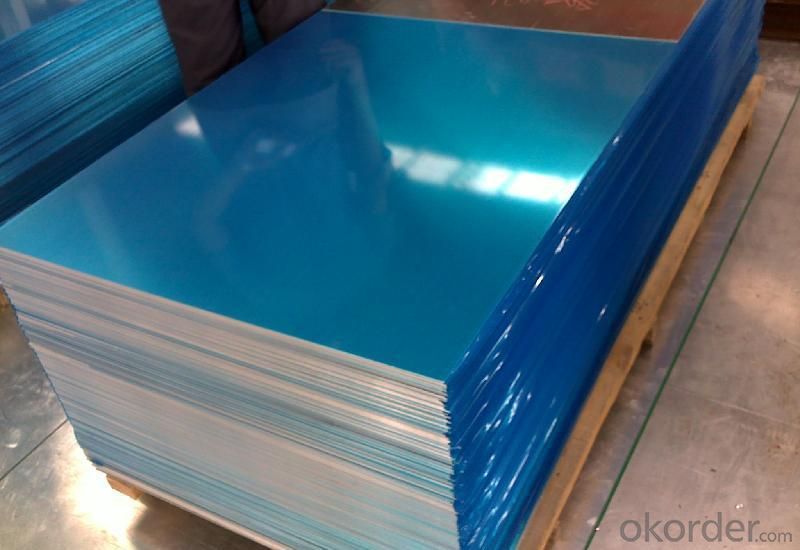

Product | Aluminum sheet |

Country of Origin | China mainland |

Alloy | 7075 |

Temper | T6 |

Width | 200-1500mm |

Thinkness | 6-100mm |

Length | less than 8000mm |

MOQ | according to different size,normal 5 tons |

Payment Terms | T/T;L/C |

Loading Port | DaLian,Tianjing,Shanghai |

Delivery Time | Within 30 days after receiving the prepayment or original L/C |

Description

According to the composition of alloy, it can be divided into 5 items.

1) High purity aluminum plate (rolling by the content above 99.9 high purity aluminum)

2) Pure aluminum plate (rolled by pure aluminum)

3) Alloy aluminum plate (composition of aluminum and other alloy material, usually alu-copper, alu-manganese, alu-silicon, alu-magnesium, and so on)

4) Composite aluminum plate or brazing plate (made by a variety of composite materials)

5) Alclad aluminum (coated aluminium sheet outside of aluminium sheet used for special purposes)

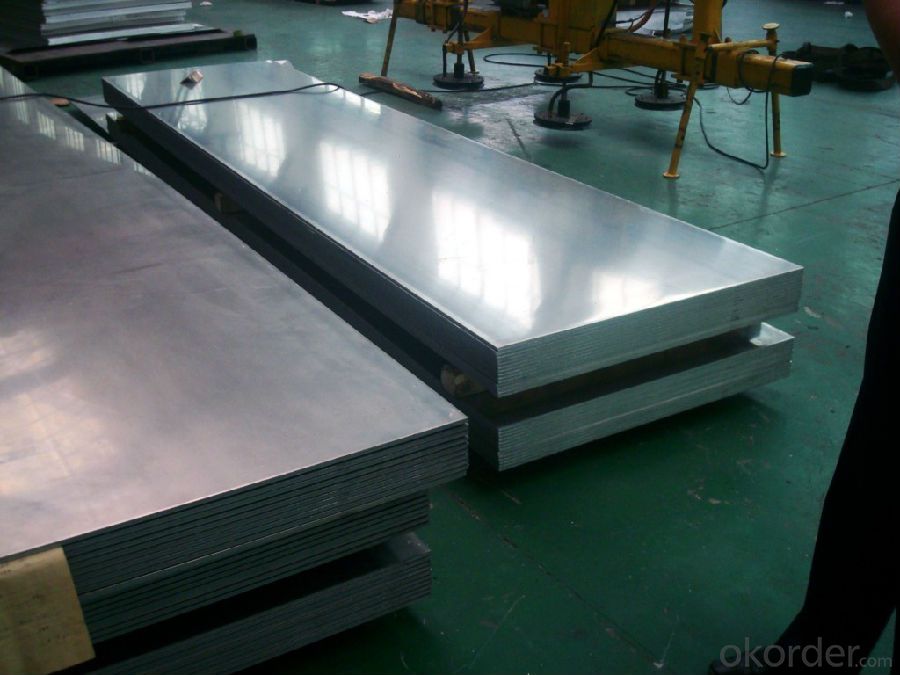

According to the thickness, it can be divided into 4 items.

1) Thin plate (aluminum sheet) 0.15-2.0mm

2) The conventional plate (aluminum sheet) 2.0-6.0mm

3) Medium plate (aluminum plate) 6.0-25.0mm

4) Thick plate (aluminum plate) 25-200mm

5) More than 200 super- thick plate

FAQ

Q: How can I request a product sample? A: The samples are free but freight should be collected. Please send sample list and courier account number by email.

Q: How can I request a product catalog? A: The hard copies of catalogs are free but freight should be collected. Please send courier account number by email. You are suggested to request a PDF catalog.

Q: Wha's your payment terms? A: One is T/T 30% before production and 70% against copy of B/L; the other is Irrevocable L/C 100% at sight.

Q: What's your trade terms? A: FOB, CNF(CFR), CIF, EXW.

Q: How long is the quality guarantee? A: All of our products have a period of quality guarantee since time of shipment. Please contact your salesman for more details, as different products enjoy different time of guarantee

- Q: Is plastic or alumium container more harmful to store food in if it does get to the food while heating.

- Neither is great, but aluminum is worse (especally when heated). Also you can't put aluminum in the microwave since it sparks (technically it should not be used for cooking), but plastic leaches stuff info food, especially if it's via ceranwrap on top (in a microwave). Storing things in platic tupperware in the fridge is fine since the temperatures are cold enough that no reactions can happen, but for cooking and eating, ceramic is preferable. Aluminum on the other hand should just be avoided (for baking pyrex glass/ceramic is better). Out of all the forms of aluminum, aluminum foil is the most likely to leech stuff. Hope that helps!

- Q: Can aluminum sheet be bent or formed into different shapes?

- Indeed, aluminum sheet possesses the capacity to be effortlessly bent or molded into diverse forms. As a remarkably ductile metal, aluminum can be bent, shaped, or molded without any risk of cracking or fracturing. This characteristic renders it a perfect selection for a wide array of applications where adaptability and customization are essential. Multiple techniques, including the utilization of a brake press, roll forming, or specialized bending tools, can be employed to bend aluminum sheets. The degree of bendability may vary based on the thickness and grade of the aluminum sheet. Nevertheless, in general, aluminum is renowned for its exceptional malleability and aptitude to assume various configurations.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- From a material standpoint, an aluminum tube bicycle is more expensive to produce. The raw materials are more expensive and the material is more difficult to weld. It started with steel, aluminum took off in the 90's, and now carbon fiber is becoming more popular. The progression has equated to lighter frames with greater comfort, but at increased costs. The increased comfort has come from tube shape factors (oval, etc.) and the strategic placement of carbon fiber in the seat stays. The material properties of steel and aluminum are highly dependent on composition, i.e. alloying elements added. If a steel frame costs more it's because the specialty manufacturer is either using an exotic alloy (Cr, Mo, V) or just gouging on the fact that there are fewer steel frame producers. Generally steel frames have better dampening properties but at a weight penalty compared to aluminum. Since steel has a higher yield strength and higher fatigue life at a given stress level so it can get away with ever thinner tube cross sections. Personally I want a bike made of Beryllium, I wonder if there is a Be-Li alloy out there (I'd have to check the valence, but not motivated right now). That would have a good strength to weight ratio, it would just have to be coated.

- Q: what's the difference between zinc sheet and aluminum sheet?

- Only zinc sheet can react, zinc is amphoteric.

- Q: What is the typical thickness tolerance for aluminum sheets?

- The typical thickness tolerance for aluminum sheets can vary depending on the specific application and industry standards. However, in general, the accepted thickness tolerance range for aluminum sheets is typically within ± 0.005 to ± 0.015 inches. This means that the actual thickness of the sheet may vary within this tolerance range from the specified thickness. It is important to note that different industries may have different tolerance requirements based on the intended use of the aluminum sheet, so it is always advisable to consult the relevant industry standards or specifications for specific tolerance requirements.

- Q: How does the thermal conductivity of aluminum compare to other metals?

- Compared to many other metals, aluminum boasts a relatively high thermal conductivity. It is often hailed as one of the foremost heat conductors among common metals. With a thermal conductivity of approximately 205 watts per meter kelvin (W/m·K), aluminum surpasses copper (about 401 W/m·K) and even silver (about 429 W/m·K). As a result, aluminum excels at efficiently transferring heat, making it a widely favored option for heat sinks, radiators, and various applications necessitating effective heat dissipation. Nonetheless, it is worth mentioning that certain metals, such as diamond and graphene, surpass aluminum in terms of thermal conductivity.

- Q: Are the aluminum sheets suitable for decorative purposes?

- Indeed, decorative purposes can be served by aluminum sheets. Aluminum, a material known for its versatility, can be effortlessly molded, trimmed, and maneuvered to produce a myriad of decorative components. Its lightweight nature, durability, and resistance to corrosion contribute to its widespread adoption for both indoor and outdoor uses. The availability of aluminum sheets in a vast array of finishes, colors, and patterns further amplifies the scope for limitless design options. Whether it is for embellishing architectural accents, crafting signage, manufacturing furniture, or producing artwork, aluminum sheets possess the potential to elevate the visual allure of any given area.

- Q: Can aluminum sheet be used for reflective surfaces?

- Indeed, reflective surfaces can be achieved with the use of aluminum sheet. Renowned for its exceptional reflectivity, aluminum is widely preferred for an array of applications that call for reflective surfaces. By skillfully polishing aluminum sheets, they can attain a remarkable luster, enabling them to reflect light and produce a mirror-like effect. Consequently, they prove to be the perfect choice for applications such as lighting fixture reflectors, solar panels, mirrors, and decorative purposes. Moreover, owing to its reflective properties, aluminum is an ideal material for situations necessitating heat reflection, including thermal insulation and roofing materials. In summary, aluminum sheets offer versatility and effectiveness when it comes to generating reflective surfaces.

- Q: Are aluminum sheets suitable for aircraft panels?

- Yes, aluminum sheets are suitable for aircraft panels. Aluminum is a widely used material in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and formability. It offers durability and structural integrity while keeping the weight of the aircraft relatively low. Aluminum sheets are commonly used for constructing aircraft panels, providing a reliable and efficient solution for aerospace applications.

- Q: Can 101 aluminum sheets be polished to a mirror-like finish?

- Yes, 101 aluminum sheets can be polished to a mirror-like finish.

Send your message to us

Aluminum Sheets in Kansas - Cold Rolled Stucco Embossed Aluminium Checker Plate 5 Bars

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords