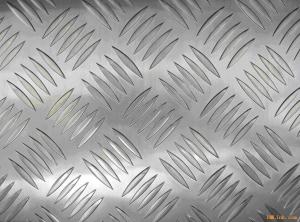

Aluminum Sheets for Sale Edmonton - Mirror Five Bars Embossed Aluminum Sheet, Aluminum Checker Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

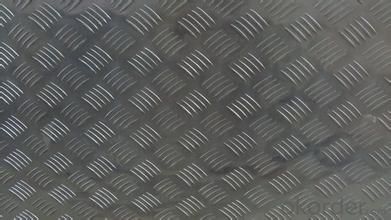

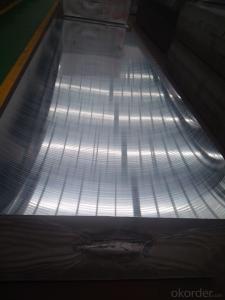

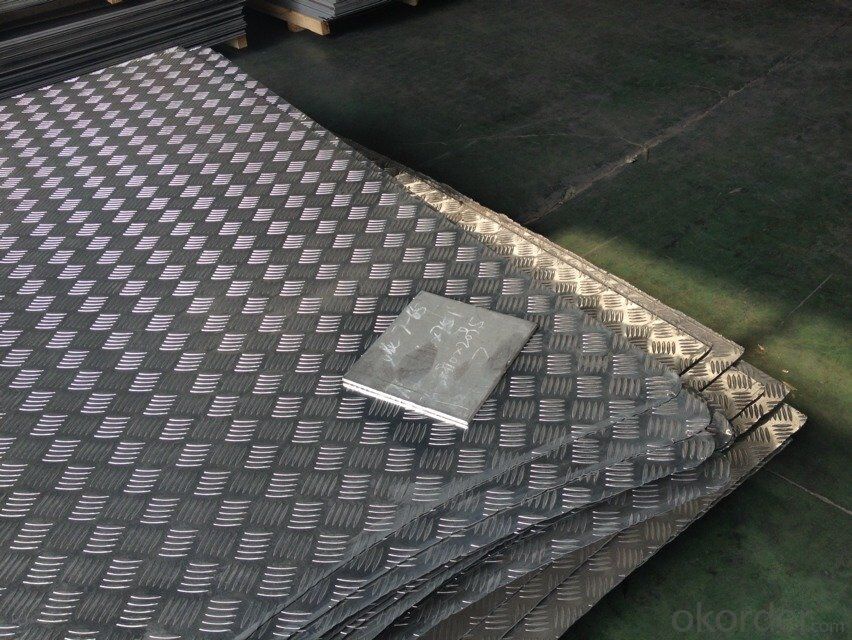

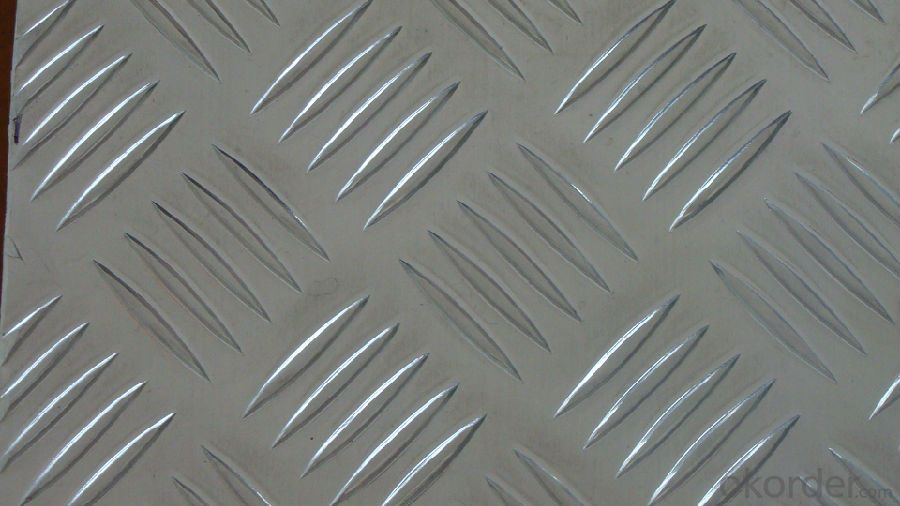

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- Scrap yards and recyclers.

- Q: What are the safety considerations when handling and working with aluminum sheets?

- When handling and working with aluminum sheets, there are several safety considerations that should be taken into account. Firstly, it is important to wear appropriate personal protective equipment (PPE). This includes safety glasses or goggles to protect the eyes from any potential flying debris or metal shards. Additionally, gloves should be worn to protect the hands from sharp edges or cuts. Secondly, it is crucial to handle aluminum sheets with care, as they can be quite sharp. When lifting or moving the sheets, it is recommended to use gloves and other tools to minimize the risk of injury. Additionally, it is important to be mindful of the weight of the sheets to avoid strains or back injuries. Another safety consideration is the potential for fire hazards. Aluminum is a highly flammable material, especially in the form of fine dust or shavings. Therefore, it is important to keep the work area clean and free from any loose aluminum debris. It is also advisable to have appropriate fire extinguishing equipment nearby and to be aware of the location of emergency exits. Furthermore, when cutting or shaping aluminum sheets, it is important to use proper techniques and tools. Using the appropriate saws or shears can help minimize the risk of injury. It is also important to secure the sheets properly to prevent them from moving or falling during the cutting process. Lastly, it is important to be aware of any potential health hazards associated with aluminum. Aluminum dust or fumes can be harmful if inhaled, so it is important to work in a well-ventilated area or use respiratory protection if necessary. In summary, the safety considerations when handling and working with aluminum sheets include wearing appropriate PPE, handling the sheets with care, minimizing fire hazards, using proper cutting techniques and tools, and being aware of potential health hazards. By following these precautions, the risks associated with working with aluminum sheets can be minimized, ensuring a safe working environment.

- Q: Are there any health risks associated with using aluminum sheets?

- The use of aluminum sheets has sparked ongoing debate and research due to potential health risks. Although aluminum is widely utilized in various industries and products, it is crucial to consider certain factors. Health issues have been linked to exposure to high levels of aluminum through inhalation or ingestion. Studies suggest that aluminum exposure may be connected to neurological disorders like Alzheimer's disease or Parkinson's disease, as well as respiratory problems and bone disorders. Nevertheless, it is important to note that these studies have not definitively established a causal relationship between aluminum and these health conditions. The primary concern with aluminum lies in its ability to leach into food or beverages when it comes into contact with acidic or salty substances. This leaching can happen during food preparation or storage, especially when using aluminum cookware or foil. Consuming excessive amounts of aluminum through food or drink may pose health risks, especially for individuals with kidney disease or those who are more susceptible to aluminum toxicity. To minimize potential health risks, it is recommended to avoid using aluminum cookware or foil when cooking or storing acidic or salty foods. Instead, consider utilizing alternatives such as stainless steel, glass, or silicone. In conclusion, while there are worries about the potential health risks associated with using aluminum sheets, further research is necessary to establish a clear cause-and-effect relationship. It is wise to reduce exposure to aluminum, particularly through food and beverages, by taking preventive measures and employing alternative materials when suitable. Seeking guidance from healthcare professionals and staying informed about the latest research can assist individuals in making informed decisions regarding the use of aluminum sheets and other aluminum products.

- Q: I can't seem to find what uses or contains Aluminum Nitride. Help!

- Don't know where you looked, but this came up with very basic web search. Metallization methods are available to allow Aluminium nitride to be used in electronics applications similar to those of alumina and beryllium oxide. Among the applications of Aluminium nitride are opto-electronics, dielectric layers in optical storage media, electronic substrates, chip carriers where high thermal conductivity is essential, military applications, as a crucible to grow crystals of gallium arsenide, steel and semiconductor manufacturing. Epitaxially grown thin film crystalline aluminium nitride is also used for surface acoustic wave sensors (SAW's) deposited on silicon wafers because of the Aluminium nitride's piezoelectric properties. One application is an RF filter used in mobile phones called a thin film bulk acoustic resonator (FBAR). This is a MEMS device that uses aluminium nitride sandwiched between two metal layers.

- Q: Are aluminum sheets resistant to UV radiation?

- Generally, aluminum sheets are resistant to UV radiation. Aluminum is well-known for its exceptional resistance to corrosion, which also applies to its resistance to UV radiation. The naturally formed oxide layer on the surface of aluminum acts as a shield, safeguarding it against the harmful effects of UV rays. This protective layer ensures that the aluminum does not deteriorate or fade when exposed to sunlight or other UV radiation sources. Nevertheless, it is worth noting that prolonged exposure to intense UV radiation may eventually cause some degradation or discoloration of the aluminum surface. Hence, while aluminum sheets are highly resistant to UV radiation, it is advisable to provide additional protection, such as coatings or paint, for applications that involve extended exposure to harsh UV environments.

- Q: Can aluminum sheets be easily bent or shaped?

- Yes, aluminum sheets can be easily bent or shaped due to their malleability, making them ideal for various applications in industries such as construction, automotive, and aerospace.

- Q: Can aluminum sheets be used for roofing?

- Yes, aluminum sheets can be used for roofing. Aluminum is a popular choice for roofing materials due to its durability, lightweight nature, and resistance to corrosion. Aluminum roofing sheets are known for their longevity, as they can last for several decades without the need for replacement. Additionally, aluminum has excellent reflective properties, which can help to reduce energy costs by keeping the building cooler in hot climates. Moreover, aluminum is easy to install, making it an attractive option for roofing projects. Overall, aluminum sheets are a reliable and practical choice for roofing applications.

- Q: What types of bonds can aluminum form: Covalent, Ionic and/or Metallic?Could you post the source, I've been looking for a while now :/

- Aluminum forms metallic bonds in the metal and aluminum alloys. Aluminum forms covalent bonds as with aluminum isopropoxide. Aluminum forms ionic bonds as in aluminum sulfate. Aluminum chloride is ionic in aqueous solution but molecular in solvents such as benzene.

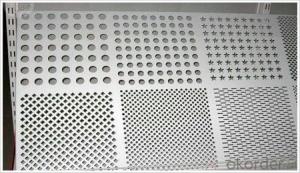

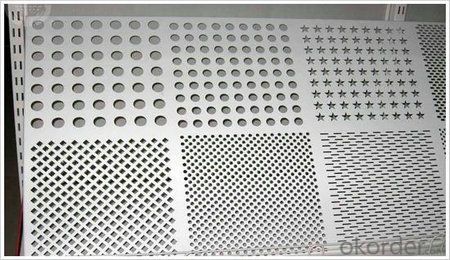

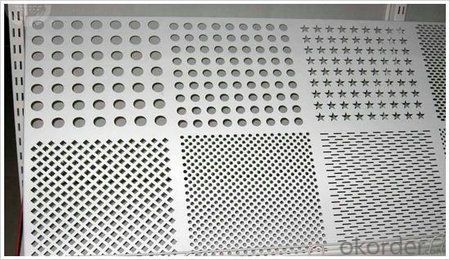

- Q: This question asks about the various patterns that can be applied to aluminum sheets, which are commonly used in construction, manufacturing, and design.

- <p>Aluminum sheet patterns are diverse and cater to various applications. Some common types include diamond, checkered, embossed, perforated, and ribbed patterns. Diamond patterns offer a classic look and are slip-resistant, while checkered patterns are often used for flooring due to their traction. Embossed patterns provide a decorative touch and can enhance surface strength. Perforated patterns are used for ventilation, light filtration, and design purposes. Ribbed patterns, also known as corrugated, offer structural strength and are used in roofing and siding applications. Each pattern serves a specific function and aesthetic, making aluminum sheets versatile for many industries.</p>

- Q: Are aluminum sheets suitable for decorative paneling?

- Yes, aluminum sheets are suitable for decorative paneling. They offer a sleek and modern appearance, are lightweight, durable, and resistant to rust and corrosion. Additionally, aluminum sheets can be easily manipulated and come in various colors and finishes, making them a versatile choice for decorative purposes.

Send your message to us

Aluminum Sheets for Sale Edmonton - Mirror Five Bars Embossed Aluminum Sheet, Aluminum Checker Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords