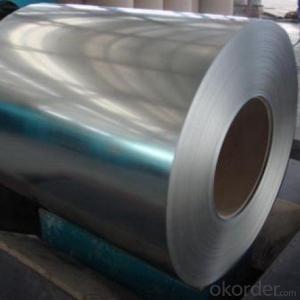

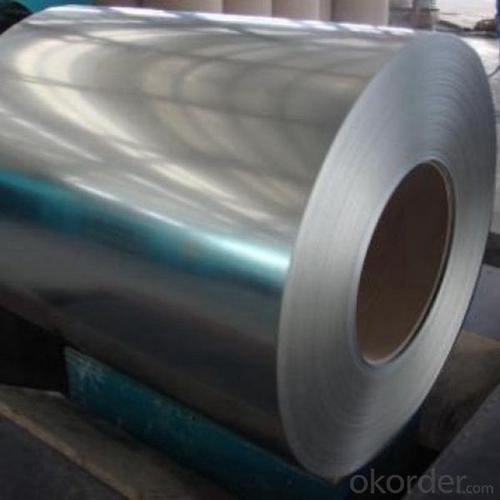

Cold Rolled Stainless Steel 2.0mm Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: How about stainless steel grades?

- According to the composition can be divided into Cr (400 Series), Cr Ni system (300 Series), Cr Mn Ni (200 Series) and the precipitation hardening systems (Series 600). 200 series - chromium nickel manganese austenitic stainless steel 300 series - chromium nickel austenitic stainless steel 301 - ductility, used for molding products. It can also be hardened rapidly by mechanical processing. Good weldability. The abrasion resistance and fatigue strength are better than 304 stainless steel. 302 - 304 with corrosion resistance, due to the relatively high carbon intensity. 303 - by adding a small amount of sulfur and phosphorus, it is easier to cut than 304.

- Q: Can stainless steel sheets be used in automotive industry?

- The automotive industry finds stainless steel sheets to be a valuable resource. This material has gained popularity due to its numerous advantageous properties. Its exceptional resistance to corrosion makes it an ideal choice for components that are exposed to harsh weather conditions, like car exteriors and body panels. Stainless steel sheets are also renowned for their impressive strength-to-weight ratio, enabling the creation of lightweight yet sturdy automobile parts. Moreover, stainless steel exhibits remarkable heat resistance and can endure high temperatures, making it suitable for applications like exhaust systems. In summary, stainless steel sheets are extensively utilized in the automotive industry because of their durability, ability to resist corrosion, and versatility in various applications.

- Q: Can stainless steel sheets be used for railway infrastructure?

- Yes, stainless steel sheets can be used for railway infrastructure. Stainless steel is a versatile and durable material that offers various advantages for railway applications. Its corrosion resistance properties make it suitable for outdoor and high humidity environments, which are common in railway infrastructure. Stainless steel sheets can withstand harsh weather conditions, including extreme temperatures, rain, and UV radiation, without corroding or deteriorating. This makes them ideal for railway tracks, bridges, tunnels, and other structures that are exposed to the elements. Additionally, stainless steel sheets have excellent strength-to-weight ratio, allowing for the construction of lightweight yet sturdy railway infrastructure. This reduces the load on the overall structure and facilitates easier transportation and installation. Stainless steel is also resistant to fire and can withstand high impact, making it a reliable choice for railway applications where safety is a priority. Furthermore, stainless steel sheets are easy to clean and maintain, which is beneficial for railway infrastructure that requires regular upkeep. They can be easily polished to restore their aesthetic appeal and maintain a clean appearance. Stainless steel is also recyclable, making it an environmentally friendly choice for sustainable railway construction. In summary, stainless steel sheets can indeed be used for railway infrastructure due to their corrosion resistance, strength, durability, fire resistance, ease of maintenance, and sustainability.

- Q: Can stainless steel sheets be used in architectural applications?

- Yes, stainless steel sheets can be used in architectural applications. Stainless steel is a versatile material that offers excellent strength, durability, and corrosion resistance, making it suitable for a wide range of architectural projects. It is commonly used for cladding, roofing, and facade applications, as well as for structural elements such as columns and beams. Stainless steel sheets can be fabricated into various shapes and sizes, allowing architects to achieve unique designs and create visually appealing buildings. Additionally, stainless steel's aesthetic appeal, with its sleek and modern look, is often sought after in contemporary architecture. Overall, stainless steel sheets are a popular choice in architectural applications due to their functionality, durability, and aesthetic qualities.

- Q: What are the common uses of stainless steel sheets?

- Stainless steel sheets have a wide range of applications due to their unique properties and versatility. Some of the most common uses include: 1. Construction: Stainless steel sheets are extensively used in the construction industry for roofing, cladding, and facades. They offer excellent durability, corrosion resistance, and a modern aesthetic appeal. 2. Automotive: Stainless steel sheets find applications in the automotive industry for manufacturing various components such as exhaust systems, grilles, trims, and decorative elements. Their resistance to heat, corrosion, and impact makes them ideal for these purposes. 3. Kitchen appliances: Stainless steel sheets are commonly used in the manufacturing of kitchen appliances like refrigerators, ovens, dishwashers, and sinks. Their hygienic properties, resistance to stains, and easy maintenance make them a popular choice for these applications. 4. Food processing: Stainless steel sheets are widely used in the food processing industry due to their non-reactive nature and ease of cleaning. They are used for making equipment such as storage tanks, conveyor systems, work surfaces, and food preparation tables. 5. Medical equipment: Stainless steel sheets are crucial in the manufacturing of medical equipment and devices. They are used for surgical instruments, dental tools, implantable devices, and hospital furniture due to their biocompatibility, corrosion resistance, and ease of sterilization. 6. Aerospace: Stainless steel sheets are utilized in the aerospace industry for constructing aircraft components like fuselage frames, engine parts, and landing gear. Their high strength-to-weight ratio, resistance to extreme temperatures, and corrosion resistance make them suitable for these demanding applications. 7. Energy and power generation: Stainless steel sheets are commonly used in power plants, oil refineries, and chemical processing plants for constructing equipment like heat exchangers, boilers, and storage tanks. Their ability to withstand high temperatures, pressure, and corrosive environments is essential in these industries. 8. Decorative purposes: Stainless steel sheets are also used for decorative purposes in architecture and interior design. They can be used to create unique and modern finishes on walls, ceilings, furniture, and decorative panels. Overall, stainless steel sheets are a versatile material used in various industries due to their exceptional properties like corrosion resistance, durability, hygienic properties, and aesthetic appeal.

- Q: Are stainless steel sheets suitable for fire-rated applications?

- Yes, stainless steel sheets are suitable for fire-rated applications. Stainless steel has excellent fire resistance properties, including high melting point and low thermal conductivity, which make it highly resistant to fire and heat. It does not contribute to the spread of flames and is often used in fire-rated doors, walls, and other applications where fire protection is required.

- Q: Are stainless steel sheets resistant to high temperatures?

- Yes, stainless steel sheets are generally resistant to high temperatures. Stainless steel is known for its excellent heat resistance properties, making it suitable for a wide range of high-temperature applications. The composition of stainless steel, which includes chromium, nickel, and other alloying elements, creates a protective oxide layer on its surface. This oxide layer acts as a barrier against oxidation and prevents the steel from corroding or weakening at elevated temperatures. Stainless steel sheets can withstand temperatures up to around 1500°F (815°C) without losing their structural integrity. However, the exact temperature resistance may vary depending on the specific grade and thickness of the stainless steel sheet. It is always recommended to consult the manufacturer's specifications or seek professional advice for specific high-temperature applications.

- Q: Can stainless steel sheets be used for outdoor signage?

- Yes, stainless steel sheets can be used for outdoor signage. Stainless steel is a durable and corrosion-resistant material that can withstand harsh weather conditions and maintain its appearance over time. It is commonly used in outdoor signage due to its ability to resist rust, fading, and damage from exposure to sunlight, rain, snow, and other environmental elements. Additionally, stainless steel sheets can be customized with various finishes, such as brushed or polished, to enhance their visual appeal and make them suitable for any outdoor signage application.

- Q: Can stainless steel sheets be used for food packaging or containers?

- Food packaging or containers can indeed utilize stainless steel sheets. The food industry widely employs stainless steel due to its numerous advantageous qualities. Its corrosion resistance guarantees that the food will not react with the container, ensuring safety for consumption. Moreover, stainless steel is highly durable, making it appropriate for long-term utilization in food packaging or containers. It is also effortless to clean and maintain, meeting the necessary hygiene standards. Furthermore, stainless steel containers or packaging can withstand extreme temperature changes, making them suitable for diverse food storage and transportation requirements. All in all, stainless steel sheets are a dependable and secure option for food packaging or containers.

- Q: Are stainless steel sheets good for heat exchangers?

- Stainless steel sheets, indeed, prove to be a fitting option for heat exchangers. The choice of stainless steel in heat exchangers stems from its remarkable resistance to corrosion, ability to endure high temperatures, and impressive strength. Its capability to withstand extreme temperatures and pressures renders it a perfect fit for diverse industrial purposes. Moreover, stainless steel sheets possess commendable thermal conductivity, which facilitates efficient heat transfer between fluids. The durability and resilience of these sheets against fouling and scaling further enhance their aptness for heat exchangers, guaranteeing enduring performance and dependability.

Send your message to us

Cold Rolled Stainless Steel 2.0mm Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords