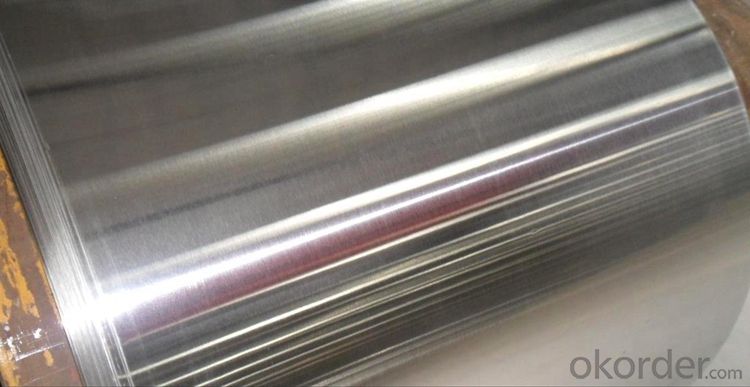

Stainless Plates NO.2B Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Type | 200 series,300 series,400 series |

Thickness | 1.8-8.0mm |

Widthness | 1000/1219/1500mm |

Technique | Hot Rolled/Cold Rolled |

Coil Weight | About 20 Tons |

Finish | NO.1/NO.2B |

Place of Origin | Made in China |

MOQ | 18 ton |

Color | Black,Mirror Finished |

Standard | ASTM, JIS, GB, BS, DIN etc |

Exporting countries | Peru,India,Pakistan,Singpore,Vietnam,South Korea,Malaysia etc. |

After-sales service | Factory Inspection |

Certifications | ISO,SGS |

Packaging | Standard export packing or following customer's demand |

Application for Stainless Steel Coils/Sheets:

Boiler heat exchanger, machinery andpetroleum ,chemical industries, hardware fields,Food industry,construction material,kitchen utensils, building construction, medical equipment,chemical tank, pipe etc

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: How thick is 10gauge in stainless steel plate?

- The word "gauge" is interesting. This term is often seen in articles reading about metal roofs. It is not a unit of measurement, but a standard measure of width or thickness.

- Q: Can stainless steel sheets be used for airport terminals?

- Airport terminals can indeed make use of stainless steel sheets. Stainless steel, being an incredibly adaptable material, offers numerous advantages when employed in airport terminals. Initially, stainless steel boasts corrosion resistance, a crucial feature in a bustling environment like an airport where exposure to moisture and chemicals is commonplace. This characteristic guarantees that the structural integrity and appearance of the stainless steel sheets will endure over time. Furthermore, stainless steel sheets possess durability, enabling them to withstand heavy foot traffic and the wear and tear associated with airport operations. Consequently, they can be utilized for a variety of purposes within the terminal, including walls, ceilings, cladding, countertops, and furniture. Additionally, stainless steel is easy to clean and maintain, making it a hygienic choice for areas with high foot traffic, such as airport terminals. Moreover, stainless steel brings forth an aesthetic appeal that can enhance the overall design of the airport terminal. Its sleek and modern appearance can create a sense of sophistication and elegance. Stainless steel sheets are available in different finishes, such as brushed, polished, or patterned, allowing for customization to meet the desired aesthetic requirements of the terminal. In conclusion, due to their corrosion resistance, durability, ease of maintenance, and aesthetic versatility, stainless steel sheets prove to be a practical and visually pleasing option for airport terminals.

- Q: Are stainless steel sheets suitable for marine applications?

- Yes, stainless steel sheets are highly suitable for marine applications. They possess excellent corrosion resistance properties and can withstand the harsh conditions of saltwater environments, making them ideal for use in marine applications such as boat fittings, offshore structures, and shipbuilding.

- Q: What are the different types of stainless steel sheet finishes available?

- Available are various types of finishes for stainless steel sheets, each possessing its own distinct characteristics and applications. Some of the most commonly used finishes include: 1. No. 1 Finish, also referred to as hot rolled or annealed and pickled finish, represents the most basic type of stainless steel sheet finish. It exhibits a rough and dull appearance with a non-reflective surface. This finish is typically employed in industrial applications where aesthetics are not of primary importance. 2. No. 2B Finish is a smooth and semi-reflective finish achieved through cold rolling, annealing, and pickling. It boasts a slightly glossy appearance and is commonly utilized in applications requiring a moderate level of corrosion resistance. 3. No. 4 Finish is accomplished through the polishing of the stainless steel sheet using a fine abrasive material. This finish presents a brushed appearance with a low gloss finish. It finds frequent use in architectural and decorative applications, such as kitchen appliances, countertops, and elevator panels. 4. No. 8 Finish, also known as a mirror finish, is the most reflective type of stainless steel sheet finish available. It is achieved by progressively polishing the surface with finer grits until a mirror-like finish is attained. This finish is frequently employed in decorative applications, including architectural accents, signage, and ornamental pieces. 5. Satin Finish exhibits a smooth, satin-like appearance with a low to medium gloss level. It is achieved through a combination of brushing and polishing techniques. This finish is often utilized in applications that require a balance between aesthetics and functionality, such as kitchen equipment, sanitary appliances, and automotive trim. 6. Bead Blasted Finish is accomplished by subjecting the surface of the stainless steel sheet to high-pressure blasting with glass beads. This creates a uniform and matte appearance with a subtle texture. It is commonly used in architectural and interior design applications, such as wall panels, elevator doors, and furniture. 7. Embossed Finish is achieved by mechanically imprinting a pattern onto the surface of the stainless steel sheet. This creates a textured appearance that can range from subtle to dramatic, depending on the chosen pattern. It is often employed in decorative applications, such as wall cladding, signage, and decorative panels. These examples merely scratch the surface of the numerous stainless steel sheet finishes available. The choice of finish depends on the specific requirements of the application, including considerations of aesthetics, corrosion resistance, and functionality.

- Q: How do I choose the appropriate gauge for stainless steel sheets?

- When choosing the appropriate gauge for stainless steel sheets, there are a few factors to consider. First, you need to determine the intended use of the sheets. Thicker gauges offer more strength and durability, making them suitable for heavy-duty applications like industrial machinery or construction. If you require flexibility or a lighter weight, thinner gauges may be more appropriate for applications such as automotive or decorative purposes. Additionally, consider the environmental conditions the sheets will be exposed to, as this may affect the required gauge for corrosion resistance. Ultimately, consulting with a stainless steel supplier or industry expert can help you select the most suitable gauge based on your specific needs.

- Q: Can stainless steel sheets be used in chemical processing plants?

- Yes, stainless steel sheets can be used in chemical processing plants. Stainless steel is highly resistant to corrosion, making it an ideal material for use in environments where chemicals are present. It can withstand exposure to a wide range of chemicals, including acids, alkalis, and solvents, without deteriorating or reacting with them. Stainless steel sheets are also easy to clean and maintain, ensuring that they meet the strict hygiene and safety standards required in chemical processing plants. Additionally, stainless steel has excellent strength and durability, making it suitable for various applications within the plant, such as tanks, piping, pressure vessels, and heat exchangers. Overall, stainless steel sheets are a reliable and versatile choice for use in chemical processing plants.

- Q: How do stainless steel sheets compare to other materials?

- Stainless steel sheets offer several advantages over other materials. They are highly resistant to corrosion, heat, and chemicals, making them suitable for various applications. Stainless steel is also durable, strong, and low maintenance, providing long-term value. Additionally, it has an attractive appearance and can be easily fabricated into different shapes and sizes. Overall, stainless steel sheets outperform many other materials in terms of performance, aesthetics, and longevity.

- Q: What are the different types of edge finishes for stainless steel sheets?

- There are several types of edge finishes for stainless steel sheets, including square edge, round edge, beveled edge, and rolled edge. Each of these finishes provides a different aesthetic and functional appeal, catering to different design preferences and project requirements.

- Q: What is the water resistance of stainless steel sheets?

- The water resistance of stainless steel sheets is typically high due to their nonporous nature and corrosion-resistant properties.

- Q: Can stainless steel sheets be used for electrical enclosures?

- Yes, stainless steel sheets can be used for electrical enclosures. Stainless steel has excellent corrosion resistance, good mechanical properties, and high durability, making it suitable for protecting electrical components in various environments. Additionally, stainless steel's conductivity and ability to dissipate heat make it a reliable choice for electrical enclosures.

Send your message to us

Stainless Plates NO.2B Cold Rolled From China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords