Steel Sheet Cold Rolled Stainless Steel Made in China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Specifications for Stainless Steel Coils/Sheets:

Grade | C ≤ | Si ≤ | Mn ≤ | P ≤ | S ≤ | Ni ≤ | Cr ≤ |

201 | 0.12 | 0.75 | 7.00 | 0.045 | 0.045 | 1.00-1.28 | 13.70-15.70 |

202 | 0.15 | 1.00 | 2.25 | 0.045 | 0.045 | 4.07-4.17 | 14.00-16.00 |

304 | 0.08 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-11.00 | 18.00-20.00 |

304L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 8.00-13.00 | 18.00-20.00 |

309 | 0.15 | 0.75 | 2.00 | 0.045 | 0.03 | 12.00-15.00 | 22.00-24.00 |

310S | 0.08 | 1.50 | 2.00 | 0.045 | 0.03 | 19.00-22.00 | 24.00-26.00 |

316 | 0.08 | 1.00 | 2.00 | 0.045 | 0.03 | 10.00-14.00 | 16.00-18.00 |

316L | 0.035 | 0.75 | 2.00 | 0.045 | 0.03 | 10.00-15.00 | 16.00-18.00 |

321 | 0.04-0.10 | 0.75 | 2.00 | 0.045 | 0.03 | 9.00-13.00 | 17.00-20.00 |

405 | 0.08 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

409 | 0.089 | 1.00 | 1.00 | 0.045 | 0.05 | 0.06 | 10.50-11.75 |

410 | 0.15 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 11.5-13.5 |

420 | 0.16-0.25 | 1.00 | 1.00 | 0.040 | 0.03 | 0.06 | 12.00-14.00 |

430 | 0.12 | 0.75 | 1.00 | 0.045 | 0.03 | 0.06 | 16.00-18.00 |

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

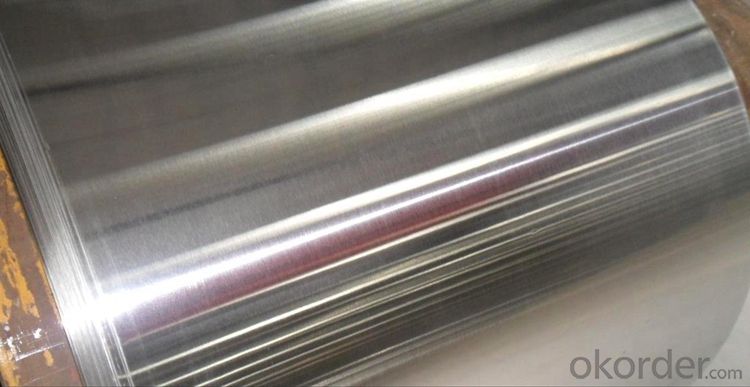

Detail picture for Stainless Steel Coils/Sheets

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

FAQ for Stainless Steel Coils/Sheets:

Q: How can I get the samples?

A: If you need some samples to test ,please pay for the transportation freight of samples and our samples are free for you.

Q: How can I get your price list?

A: Please send us your email or fax and order information – Quantity, Specification (steel type, thickness, width, surface finish), then I can send you the price list.

- Q: What is the elongation of stainless steel sheets?

- The elongation of stainless steel sheets refers to the ability of the material to stretch or deform under tension before breaking. It is typically expressed as a percentage and represents the maximum strain the steel can undergo without fracturing.

- Q: How do you remove scratches from stainless steel sheets?

- There are a few methods you can try to remove scratches from stainless steel sheets. One option is to use a non-abrasive cleaner or stainless steel polish, applying it with a soft cloth and gently rubbing the scratched area in a circular motion. Another method involves making a paste using baking soda and water, applying it to the scratch, and gently rubbing it with a soft cloth. Additionally, you can use a fine-grit sandpaper to lightly buff the scratch in the direction of the grain. Remember to always test these methods on a small, inconspicuous area first to ensure they do not damage the stainless steel.

- Q: What are the different types of stainless steel sheet finishes for architectural applications?

- There are several different types of stainless steel sheet finishes that are commonly used in architectural applications. These finishes are applied to the surface of the stainless steel sheet to enhance its appearance and provide additional protection against corrosion and wear. 1. No. 1 Finish: This is the most common type of stainless steel sheet finish. It is also known as "hot rolled annealed and pickled" finish. In this finish, the stainless steel sheet is hot rolled, resulting in a dull, rough surface. It is then annealed and pickled to remove any scale or impurities, leaving a clean, uniform surface. 2. No. 2B Finish: This finish is achieved by cold rolling the stainless steel sheet after it has been annealed and pickled. It results in a smooth, reflective surface with a slight grainy texture. No. 2B finish is commonly used for applications that require a high level of corrosion resistance and a polished appearance. 3. No. 4 Finish: Also known as "brushed finish," No. 4 finish is achieved by mechanically polishing the stainless steel sheet with abrasive belts or brushes. It creates a satin-like appearance with fine parallel lines. No. 4 finish is often used for decorative purposes in architectural applications such as wall panels, elevator interiors, and column covers. 4. No. 8 Mirror Finish: This finish is achieved by mechanically polishing the stainless steel sheet to a highly reflective mirror-like surface. It provides a bright, reflective appearance and is commonly used for decorative applications such as wall cladding, signage, and decorative trim. 5. Bead Blasted Finish: In this finish, the stainless steel sheet is blasted with fine glass beads to create a textured, matte surface. Bead blasted finish offers a unique aesthetic and is often used in applications where a non-reflective, tactile surface is desired, such as elevator doors, handrails, and countertops. 6. Patterned Finish: Patterned finishes are achieved by embossing or etching the stainless steel sheet with various patterns or textures. This creates a decorative surface that adds visual interest to architectural applications. Patterned finishes are commonly used for wall panels, ceiling tiles, and decorative screens. These are just a few of the most common stainless steel sheet finishes used in architectural applications. Each finish offers its own unique aesthetic and functional characteristics, allowing architects and designers to choose the most suitable finish for their specific project requirements.

- Q: Are stainless steel sheets resistant to galvanic corrosion?

- Yes, stainless steel sheets are resistant to galvanic corrosion. Galvanic corrosion occurs when two dissimilar metals come into contact in the presence of an electrolyte, such as moisture or saltwater. In such cases, one metal acts as an anode and the other as a cathode, leading to the transfer of electrons and the corrosion of the anode. Stainless steel is an alloy that contains chromium, which forms a passive oxide layer on its surface. This oxide layer acts as a protective barrier, preventing the transfer of electrons and thus effectively resisting galvanic corrosion. The chromium in stainless steel reacts with oxygen in the air to create a thin, invisible, and self-repairing layer of chromium oxide. This layer provides excellent corrosion resistance and makes stainless steel highly resistant to galvanic corrosion when in contact with other metals. However, it is important to note that the level of corrosion resistance may vary depending on the specific grade and composition of stainless steel used. Some stainless steel alloys, such as Type 316 stainless steel, offer even higher resistance to galvanic corrosion due to the addition of molybdenum, which enhances its corrosion resistance in aggressive environments. In summary, stainless steel sheets are generally highly resistant to galvanic corrosion due to the presence of a passive chromium oxide layer on their surface. This makes stainless steel a reliable choice for applications where galvanic corrosion is a concern, such as in marine environments or when in contact with dissimilar metals.

- Q: Are stainless steel sheets resistant to erosion corrosion?

- Yes, stainless steel sheets are highly resistant to erosion corrosion. This is primarily due to the presence of chromium in the alloy, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion. Furthermore, stainless steel sheets are also resistant to erosion corrosion caused by various chemicals and acids. The alloy composition of stainless steel, which typically includes elements such as nickel and molybdenum, enhances its resistance to corrosion in harsh environments. This makes stainless steel sheets suitable for a wide range of applications, including in industries such as chemical processing, oil and gas, and marine. However, it is important to note that the resistance of stainless steel sheets to erosion corrosion can vary depending on the specific grade or alloy used. Different grades may have different levels of corrosion resistance, so it is essential to choose the appropriate grade based on the specific environmental conditions and requirements of the application. Regular maintenance and proper handling can also help prolong the lifespan and maintain the corrosion resistance of stainless steel sheets.

- Q: What are the different types of embossed patterns available for stainless steel sheets?

- Stainless steel sheets offer a variety of embossed patterns to choose from. Some of the commonly seen options are as follows: 1. Diamond Pattern: This pattern showcases a series of diamond-shaped raised protrusions on the sheet's surface. It is a popular choice as it adds visual interest and texture to various applications. 2. Linen Pattern: The linen pattern features parallel lines that create a textured appearance resembling linen fabric. Architects and interior designers often utilize this pattern due to its unique aesthetic. 3. Squares Pattern: As the name suggests, this design consists of square-shaped raised protrusions on the stainless steel sheet. It provides a clean and modern look, suitable for a wide range of applications. 4. Leather Pattern: The leather pattern imitates the texture and appearance of leather, adding elegance and sophistication to stainless steel sheets. It is a favored choice for decorative purposes. 5. Moire Pattern: The moire pattern creates a wavy or rippled design, resulting in an optical illusion effect. It adds a dynamic visual element to stainless steel sheets, making them stand out. 6. Checkerplate Pattern: This pattern consists of raised squares or rectangles arranged in a checkered pattern. Its high slip resistance makes it ideal for applications where safety is crucial, such as stairs or ramps. These examples represent only a fraction of the embossed patterns available for stainless steel sheets. The choice of pattern depends on aesthetic preference, functionality, and specific application requirements. Whether for architectural, interior design, or industrial purposes, there is a wide range of embossed patterns to cater to various needs.

- Q: What are the benefits of using diamond plate stainless steel sheets in industrial flooring?

- Using diamond plate stainless steel sheets in industrial flooring offers several benefits. Firstly, diamond plate stainless steel sheets provide enhanced traction due to their raised diamond pattern, which reduces the risk of slips and falls in high-traffic areas. Additionally, these sheets are extremely durable and resistant to wear, making them ideal for withstanding heavy loads and frequent foot traffic. Diamond plate stainless steel sheets are also corrosion-resistant, ensuring long-term durability and minimal maintenance requirements. Finally, the sleek and professional appearance of these sheets adds aesthetic value to industrial settings, enhancing the overall look and functionality of the flooring.

- Q: Can stainless steel sheets be used for pharmaceutical storage cabinets?

- Yes, stainless steel sheets can be used for pharmaceutical storage cabinets. Stainless steel is highly resistant to corrosion, making it an ideal material for storing pharmaceuticals, which often require sterile and hygienic conditions. Stainless steel is also easy to clean and maintain, ensuring that the storage cabinets remain contamination-free. Additionally, stainless steel is durable and long-lasting, providing a reliable and secure storage solution for pharmaceuticals.

- Q: How do I prevent fretting corrosion on stainless steel sheets?

- Fretting corrosion can be a common issue with stainless steel sheets, but there are several steps you can take to prevent it: 1. Proper Handling: When handling stainless steel sheets, it is crucial to avoid any scratching or rubbing of the surface that could lead to fretting corrosion. Use gloves and avoid contact with other metals or rough surfaces. 2. Cleaning: Regularly clean the stainless steel sheets using mild detergents or specialized stainless steel cleaners. This helps remove any contaminants that can initiate corrosion and also prevents the build-up of dirt or grime that can contribute to fretting corrosion. 3. Lubrication: Applying a suitable lubricant or anti-seize compound on the contact surfaces can minimize friction and prevent fretting corrosion. This is especially important in applications where there is repeated movement or vibration. 4. Avoiding Metal-on-Metal Contact: Whenever possible, try to isolate stainless steel sheets from direct contact with other metals. This can be done by using insulating materials, gaskets, or non-metallic spacers to create a barrier between the stainless steel and potentially corrosive materials. 5. Regular Inspection: Periodically inspect the stainless steel sheets for any signs of fretting corrosion, such as small cracks, discoloration, or pitting. Early detection allows for prompt action to prevent further damage. 6. Protective Coatings: Applying a protective coating, such as a passivation treatment or a corrosion-resistant paint, can provide an additional layer of protection against fretting corrosion. Consult with a professional to determine the most suitable coating for your specific application. 7. Proper Storage: When not in use, store stainless steel sheets in a clean, dry environment to minimize exposure to moisture or corrosive substances. Ensure that the storage area is well-ventilated and free from any contaminants that could potentially initiate fretting corrosion. By following these preventive measures, you can significantly reduce the risk of fretting corrosion on stainless steel sheets and prolong their lifespan.

- Q: Are stainless steel sheets suitable for chemical reactors?

- Yes, stainless steel sheets are indeed suitable for chemical reactors. Stainless steel is highly resistant to corrosion, which makes it an ideal material for handling various chemicals and withstanding harsh environments. Its durability, strength, and ability to maintain structural integrity under high temperatures and pressure make stainless steel sheets a reliable choice for chemical reactor construction. Additionally, stainless steel's non-reactive nature ensures that it does not contaminate or react with the chemicals being processed, ensuring the integrity and safety of the reactor.

Send your message to us

Steel Sheet Cold Rolled Stainless Steel Made in China

- Loading Port:

- Shekou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords