Cold Rolled Stainless Steel, Stainless Plates Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description for Stainless Steel Coils/Sheets:

Material | 201/202/301/304/304L/310S/316/316L/321/410/420 |

Technique | old Rolled, Cold Drawn, Hot Rolled |

Standard | ASTM,AISI,JIS,GB,DIN,EN |

Thickness | 0.3mm-100mm or as your requirement |

Width | 100mm-3000mm or as your requirement |

Length | 1000mm-10000mm or as your requirement |

Surface Treatment | BA,2B,No.1,No.4,No.8,HL,8K,Brush |

Packing | 1.Export sea worthy package + water proof paper + wooden pallet 2. Max Loading 26.5mt for each 20Gp container 3.Safe loading and fixing Professiona teams 4. Professional shipping line |

Delivery | 25 days after received the 30% deposit of T/T or L/C |

Payment | T/T,30%payment in advance,70%T/T after the copy of B/L or L/c at sight |

Application | Stainless Steel Sheets are widely used in below fields: 1: Construction field, shipping building industry 2: Petroleum and Chemical Industries 3: Food and Mechanical Industries |

Packaging & Delivery for Stainless Steel Coils/Sheets:

Packaging Detail Standard export packing or following customer's demand

Delivery Time: Within 30-40 days after deposit or according to the order quantity

Features of Stainless Steel Coils

(1)Good ductility

(2)Good corrosion resistance

(3)Excellent abrasion resistance and fatigue strength

(4)Good weldability

(5)Oxidation resistant performance

(6)Excellent in high temperature

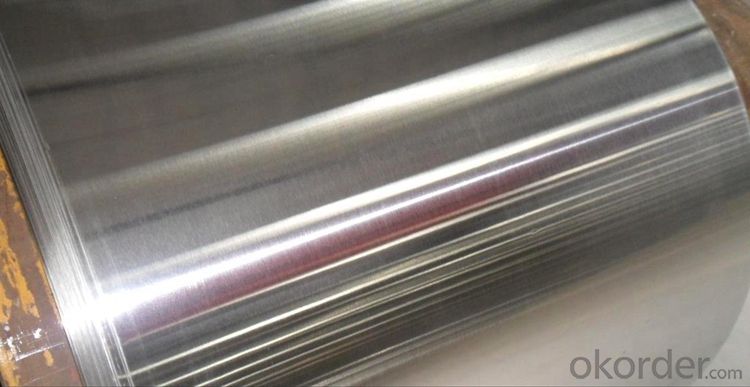

Detail picture for Stainless Steel Coils/Sheets

FAQ for Stainless Steel Coils/Sheets:

Q:How to order?

A: Please send us your purchase order by email or fax .or you can ask us to send you a proforma invoice for your order .We need to know the following information for your order.

1) Shipping information-company name, street address, phone number, fax number, destination sea port

2) Product information – Quantity, Specification (steel type, thickness, width, surface finish)

3) Delivery time required

4) Forwarder's contact details if there's any in China

- Q: Can stainless steel sheets be bent?

- Yes, stainless steel sheets can be bent. Stainless steel is a versatile material that can be easily formed into various shapes and configurations, including bends. The ability to bend stainless steel sheets is dependent on the thickness and composition of the material. Thinner sheets are generally more flexible and easier to bend, while thicker sheets may require specialized equipment and techniques. It is important to note that the bending process may cause the stainless steel sheet to lose some of its strength and durability, so careful consideration should be given to the specific application and requirements before attempting to bend stainless steel sheets.

- Q: Can stainless steel sheets be used for hygienic environments?

- Yes, stainless steel sheets are commonly used in hygienic environments due to their inherent properties such as resistance to corrosion, ease of cleaning, and ability to withstand high temperatures. These sheets are frequently used in various industries, including healthcare, food processing, and pharmaceuticals, to ensure a clean and sterile environment.

- Q: What are the different thickness tolerances for stainless steel sheets?

- There are various thickness tolerances for stainless steel sheets depending on the specific grade and industry standards. Generally, the thickness tolerances for stainless steel sheets can range from ±0.0015 inches to ±0.030 inches, with tighter tolerances being more common for precision applications.

- Q: Are stainless steel sheets suitable for storage cabinets?

- Yes, stainless steel sheets are suitable for storage cabinets. Stainless steel is known for its durability, strength, and resistance to corrosion, making it an excellent choice for storage cabinets. Stainless steel sheets are able to withstand heavy loads and can resist damage from moisture, heat, and chemicals. Additionally, stainless steel is easy to clean and maintain, making it a hygienic option for storage cabinets. Overall, stainless steel sheets provide a long-lasting and reliable solution for storage cabinets in various environments such as kitchens, laboratories, and industrial settings.

- Q: What are the standard sizes and thicknesses of stainless steel sheets?

- The standard sizes of stainless steel sheets range from 4 feet by 8 feet to 5 feet by 10 feet. The standard thicknesses vary from 0.4mm to 6mm, depending on the specific application and requirements.

- Q: Can stainless steel sheets be used for decorative ceiling tiles?

- Yes, stainless steel sheets can be used for decorative ceiling tiles. Stainless steel is a versatile material that is known for its durability, corrosion resistance, and aesthetic appeal. It can be easily customized and fabricated into various patterns, textures, and finishes, making it an excellent choice for decorative purposes. Stainless steel ceiling tiles can add a modern and sleek look to any space, whether it is a residential, commercial, or industrial setting. Additionally, stainless steel is easy to clean and maintain, making it a practical choice for areas where cleanliness is crucial.

- Q: Can stainless steel sheets be used for restaurant equipment?

- Certainly! Restaurant equipment can indeed utilize stainless steel sheets. Stainless steel is a highly favored option for restaurant equipment owing to its multitude of advantages. Its durability, resistance to corrosion, and ease of cleaning all contribute to its popularity. By employing stainless steel sheets, restaurant equipment can be crafted into diverse forms and dimensions, fulfilling the particular needs of countertops, sinks, tables, shelves, and food preparation surfaces. Moreover, stainless steel is an exceptionally hygienic substance that does not interact with food or taint it, rendering it perfect for deployment in restaurant environments where cleanliness and food safety are of utmost importance.

- Q: Can stainless steel sheets be used in high-pressure applications?

- Yes, stainless steel sheets can be used in high-pressure applications. Stainless steel is known for its strength, durability, and resistance to corrosion, making it suitable for withstanding high-pressure environments. It can be used in various industries, such as oil and gas, chemical processing, and power generation, where high-pressure conditions are present.

- Q: What brand of stainless steel plate is good?

- 201 and 202 stainless steel plate Lianzhong good, 304 cold rolled and Zhangpu new hot, TISCO good, 321, 309S, 310S of TISCO, specifically to see what material in which, stainless steel also has a lot of knowledge.

Send your message to us

Cold Rolled Stainless Steel, Stainless Plates Made in China

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m.t.

- Supply Capability:

- 200000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords