Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

1. Detailed Specifications:

| Product | Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/ |

| Base material | Hot dipped galvanized steel sheet |

| Top side: | 15-25µm |

| Back side | 5-8µm |

| Zinc coating : | 30-150g/m2 |

| Width | 700-1250mm |

| Thickness | 0.3-1.0mm , Thickness tolerance: +/- 0.02mm |

| Technique | Cold rolled—>hot dipped galvanized |

| Color | All RAL color,or be customized |

| Coil ID | 508m&610mm |

| Coil weight | ≤5 tons |

| Packing | standard seaworhty package |

| Special specifications can be negotiated. | |

2. Application:

They are mainly used in construction ,light industry, automobile, agriculture, animal husbandry, fishery and commerce,etc industries.

(1) manufacture anticorrosion, industrial and roof boarding,roof grille.

(2) Make home appliance’s case, civil chimney, kitchen utensils.

(3) Corrosion resistant parts of cars.

(4) Food storage, meat and aquatic products’ freezing and processing equipment.

(5) The equipments to store and transport materials, and packing implements.

3. Image:

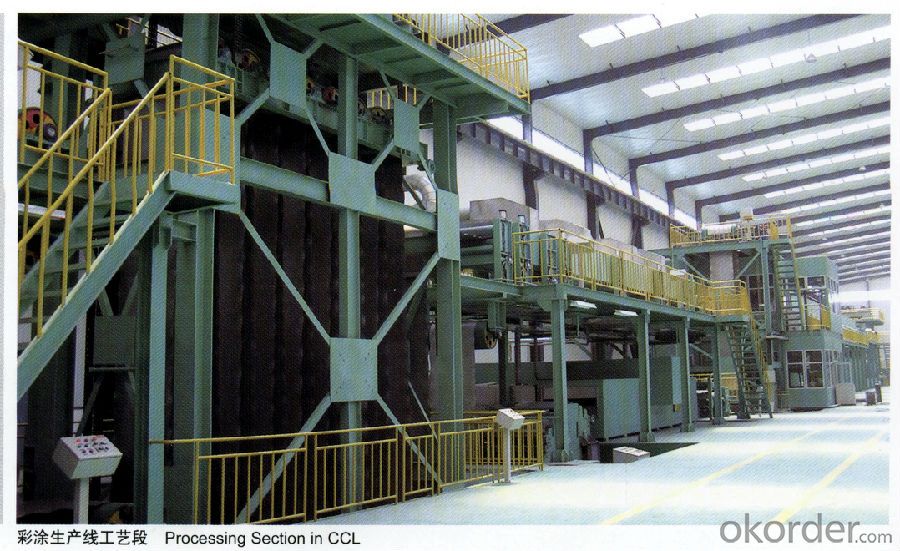

production Line:

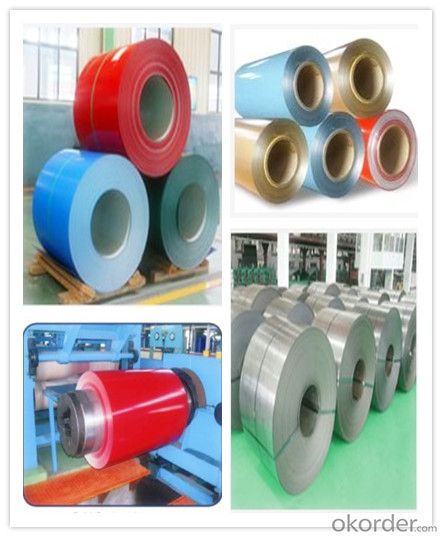

production show:

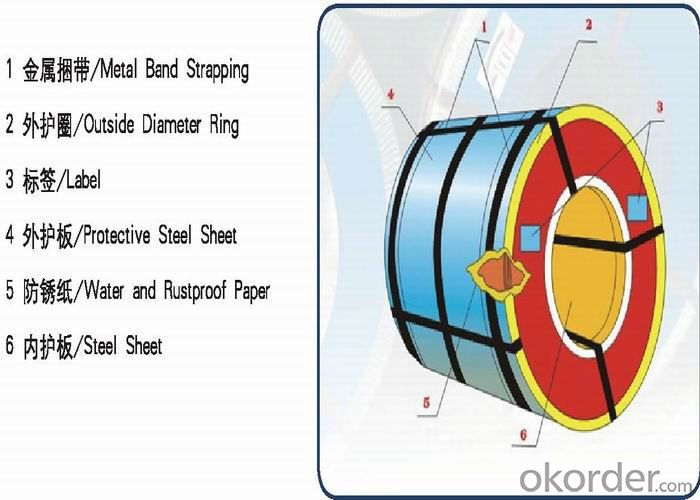

4.Packaging & Delivery

(1)Metal Band Strapping (2) Outside Diameter Ring (3) Label

(4)Protective Steel Sheet (5) Water and Rustproof paper (6)Steel Sheet

5.RFQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1Year for the whole light. Warranty is based on correct storage, installation, using and mainten anc.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as so on as possible.

- Q: What are the different types of steel coil cutting processes?

- There are several different types of steel coil cutting processes, including shearing, slitting, and laser cutting.

- Q: How do steel coils contribute to the construction industry?

- Steel coils play a crucial role in the construction industry by serving as the primary raw material for a wide range of applications. These coils are used in the construction of buildings, bridges, highways, and other infrastructure projects. They are used to manufacture various structural components, including beams, columns, and trusses, providing strength, durability, and stability to the structures. Steel coils also contribute to the industry by enabling the fabrication of roofing and siding materials, reinforcing bars, and other construction elements. Their versatility, high strength-to-weight ratio, and resistance to corrosion make steel coils an essential resource for the construction industry.

- Q: How do steel coils contribute to the HVAC ductwork industry?

- Steel coils play a crucial role in the HVAC ductwork industry by providing the necessary material for the fabrication of ducts. These coils, typically made from galvanized steel, offer several key contributions to the industry. Firstly, steel coils are highly durable and long-lasting, making them ideal for constructing HVAC ductwork. They can withstand high temperatures, pressure, and exposure to various environmental elements. This durability ensures that the ducts made from steel coils can efficiently transport air for extended periods without deteriorating or losing their structural integrity. Moreover, steel coils are flexible and malleable, allowing for easy manipulation during the fabrication process. HVAC ductwork often requires customization to fit specific building layouts and designs. Steel coils can be easily cut, bent, and shaped without compromising their strength. This flexibility enables the production of ducts in various sizes, shapes, and configurations to meet the specific requirements of different HVAC systems. Additionally, steel coils provide excellent resistance to corrosion and fire. The galvanized coating on the steel surface acts as a protective layer, preventing rust and corrosion caused by moisture or chemical reactions. This corrosion resistance ensures that the ductwork remains functional and safe for an extended period. Furthermore, steel coils contribute to the HVAC ductwork industry by enhancing energy efficiency. The smooth surface of steel coils reduces air friction and turbulence within the ducts, allowing for smoother airflow and reducing energy loss. This improved energy efficiency translates into cost savings for building owners and occupants, as it reduces the energy consumption required to maintain a comfortable indoor environment. Lastly, steel coils are readily available and cost-effective, making them a popular choice for HVAC ductwork fabrication. The abundance of steel coils in the market ensures a steady supply, allowing for efficient production and installation of ductwork systems. Furthermore, their cost-effectiveness makes them an economical option for both small and large-scale HVAC projects. In conclusion, steel coils contribute significantly to the HVAC ductwork industry by providing a durable, flexible, corrosion-resistant, energy-efficient, and cost-effective material for the fabrication of ducts. Their unique properties ensure the construction of high-quality ductwork systems that effectively and efficiently distribute air in buildings for optimal comfort and functionality.

- Q: How are steel coils used in the production of power generation equipment?

- Steel coils are used in the production of power generation equipment as they are shaped and formed into various components such as turbine casings, generator frames, and steam pipes. These coils provide the necessary strength and durability to withstand the high temperatures, pressure, and mechanical stresses involved in power generation processes. Additionally, steel coils are often coated with protective layers to prevent corrosion, ensuring the longevity and reliability of the equipment.

- Q: given the buoyant economic growth of india, what you guys think about steel industry? what can be the major issues in this industry in the coming days

- Since2003, India has been the largest sponge iron producer in the world. In 2005, out of total global production of 56.05 mt of sponge iron, India produced around 11.1 mt (19.8%). In line with production target of 110 mt of steel (National Steel Policy) by FY20, many steel producers have announced their capacity expansion plans by signing MOUs with various state governments like Chattisgarh, Orissa and Jharkhand. The steel producers are expected to add around 8 mt of capacity by FY 08. CARE estimates that during 2006-09, demand for steel in the domestic market would grow at a CAGR of 8.4%. HR steel because of its widespread applicability is expected to grow at a CAGR of 17.5%. During this period, major demand drivers would be Consumer durables, Automobiles and Construction. Domestically, steel prices of flat products follow the international trend. Globally, steel prices are expected to firm up with continued growth in steel consumption. Further, the winds of consolidation have gathered pace with Arcelor-Mittal merger and latest acquisition of Corus by Tata Steel. The Indian steel industry has announced huge capacity expansions. With commissioning of these capacities demand-capacity ratio is expected to decline in FY 09 due to excess capacity. Will this lead to a drop in prices with commissioning of these capacities? With China and India becoming the focus of major global steel companies, will the consolidation of steel industry in these countries continue? For comprehensive analysis and CARE’s future outlook on the sector, please refer to the exhaustive report on the Indian Steel Industry by CARE Research.

- Q: How are steel coils inspected for quality assurance?

- Steel coils are inspected for quality assurance through a rigorous process that involves various tests and checks. Firstly, visual inspection is conducted to look for any surface defects such as scratches, dents, or rust. This ensures that the coils are in good condition and free from any obvious flaws. Next, dimensional inspection is performed to verify the dimensions and tolerances of the coils. This involves measuring the width, thickness, and length of the coils to ensure they meet the specified requirements. Any deviations from the standard dimensions are noted and addressed. Additionally, mechanical testing is carried out to assess the strength and durability of the steel coils. This includes conducting tensile tests to measure the strength and elasticity of the steel, as well as impact tests to evaluate its ability to withstand sudden loads or shocks. Furthermore, chemical analysis is conducted to determine the composition and purity of the steel. This involves taking samples from the coils and analyzing them in a laboratory to check for the presence of any impurities or elements that may affect the quality of the steel. To ensure the coils meet specific industry standards, non-destructive testing methods such as ultrasonic testing or magnetic particle inspection may be employed. These techniques allow for the detection of internal defects or irregularities that may not be visible to the naked eye. In addition to these tests, the coils may undergo surface treatment inspections, such as galvanization or coating checks, to ensure the protective layers are applied correctly and meet the required specifications. Overall, steel coil inspection for quality assurance involves a combination of visual, dimensional, mechanical, chemical, and non-destructive testing methods. These comprehensive inspections help to ensure that the steel coils meet the necessary quality standards and are suitable for their intended applications.

- Q: i have noticed in guns, and artillery the shell casings are always made out of brass. brass is expensive, weaker and dosnt look as good as steel. so why use it for casings? i am aware some of the case must be deformed. but just a small brass percussion cap could be used just for that and steel for the rest. whats going on?

- Expansion and more resistant to rust. Besides, steel cased ammo is made in East Eur..abia in all kinds of calibers but many people complain about it not being able to expand or that the steel wears out the extractor faster (not true), then they go and buy some.

- Q: What are the common coil storage methods?

- The common coil storage methods include stacking coils vertically, using coil cradles or racks, and storing them horizontally on pallets or on the ground.

- Q: We are going to build a house with a steel frame.Someone told me today that these houses have problems with humidity.Is that true?Please tell me all you know..

- The humidity is not at all related to the framework of any house. Galvanized steel has become popular especially in commercial applications because lumber costs are increasing exponentially. Consider that any home built should be adequately ventilated, insulated, and certainly constructed. Consider where the house is,,,IE: Near water; in a tropical setting; prone to being in an area that floods; or gets a lot of rain. The exterior and interior of a steel framed house is the same as a wood frame. I'd go with block personally and steel roof rafters and joists. Once the house is built, adequate ventilating, heating, and/or air conditioning should be accomplished to keep the humidity levels tolerable, and not effect mold, mildew, excesssive heat, etc. Rev. Steven

- Q: What are the common sizes of steel coils?

- The specific needs and requirements of different industries determine the variations in common sizes of steel coils. However, the steel manufacturing and processing sectors commonly utilize standard sizes. These sizes include: 1. Slit Coils: Typically smaller, slit coils are readily available in widths ranging from 0.5 inches to 72 inches. The weight of slit coils varies, usually falling between 1000 pounds and 50,000 pounds. 2. Master Coils: Larger in size, master coils are generally utilized in steel processing facilities for the production of different steel products. The width of master coils commonly ranges from 36 inches to 96 inches, while the weight may vary from 5,000 pounds to 60,000 pounds. 3. Sheet Coils: Construction, automotive, and appliance manufacturing industries often employ sheet coils. The standard sizes for sheet coils vary, but they are commonly found in widths of 48 inches, 60 inches, and 72 inches, with lengths ranging from 96 inches to 240 inches. 4. Plate Coils: Primarily utilized in heavy-duty applications such as shipbuilding, bridge construction, and pressure vessel manufacturing, plate coils tend to be larger in size. Their widths typically range from 36 inches to 96 inches, while lengths vary from 96 inches to 480 inches. It is important to note that these sizes are not fixed and can be customized according to specific customer requirements. Steel manufacturers and suppliers possess the capability to produce coils in various sizes to cater to the diverse needs of their clients.

Send your message to us

Cold-rolled Galvanized Plate/Color Coated Galvanzied Steel Sheet/Coil/PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords