PPGI Color Coated Sheet/Color Coated Steel Coil/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Application of Color Coated Steel Coil:

Construction | Outside | Workshop, agricultural warehouse, roof panel, wall panel in steel structure in warehouse,corrugated roof, roller shutter door, rainwater drainage pipe, retailer booth |

| Inside | factories exhibition hall,doorcase, light steel roof structure, folding screen, elevator, stairway | |

Electrical appliance | Refrigerator, washer, switch cabinet, instrument cabinet, air conditioning, micro-wave oven, bread maker | |

Furniture | Central heating slice, lampshade, chifforobe, desk, bed, locker, bookshelf | |

Carrying trade | Exterior decoration of auto and train, clapboard, container, isolation lairage, isolation board | |

Others | Writing panel, garbage can, billboard, timekeeper, typewriter, instrument panel, weight sensor, photographic equipment | |

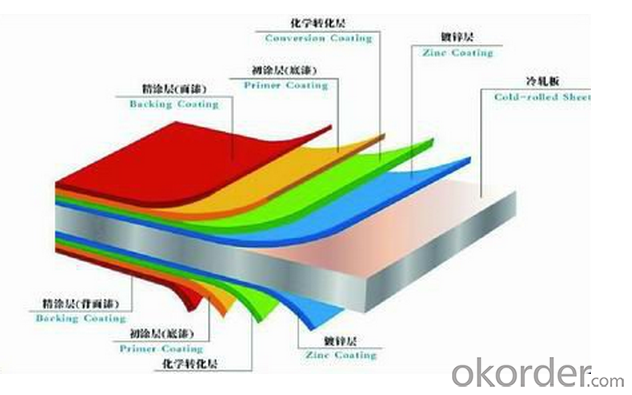

2.Features of Color Coated Steel Coil:

With excellent cold-rolling steel strips as a base material, it has the advantages of

* Good manufacturing performance

* High impact resistance

* Uniform plating thickness

* High adhesive force

* No peeling after forming

* High corrosion resistance

3.Details of Color Coated Steel Coil:

Base Material | Al-Zn Galvanized Steel Coil.SGLCC |

Top Side | 15-25 microns |

Back Side | 5-8 microns |

Width | 700-1250mm |

Thickness | 0.3-1.0mm ,thickness tolerance: +/- 0.02mm |

Al-Zn Coating | 30-150g/sq.m |

Spangle | Regular/Zero/Big |

Color | All RAL Color,or be customized |

Coil ID | 508mm&610mm |

4.Color Coated Steel Coil Image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different types of steel coil loading and unloading devices?

- There are several types of steel coil loading and unloading devices, including coil carriages, coil lifters, coil turners, coil grabs, and coil tilters. These devices are designed to safely and efficiently handle steel coils during the loading and unloading process, ensuring smooth operations in various industries such as manufacturing, construction, and transportation.

- Q: I work the Copper plating line at a custom plating facility in MI.I like to use jumper cables with the jumper cable clamps to help confirm electric current is getting to my parts that I am plating. The acids in the Acid copper is constantly eating the steel and copper clamps. WIll I get a good enough current through stainless steel clamps? I use stainless steel hooks, but our maintenance man thinks that is one of the reasons why I have prblems with my parts turning out. I still think it has to do with the clamps getting eatin up. My question is Is stainless steel as good or reliable enough to run an electrical current to my parts if I am using stainless steel or is it best to use another method to try and get a better connection.Please state your sources or experience with working with electricity. I need to get honest answers and not this is my opinion. We are talking about my making a living so this is important to me so I can bring food home to my table. Thanks for all the help.

- Stainless Steel Conductivity

- Q: Hello people.Me and the life mate have been working on a fantasy book together and we are currently in the process of outlining the cultures. The culture of our antagonists' is a sort of woodland tribal/celtic[ish] deal and they are very nature oriented. Being a detail freak and wanting to have some real world credibility in the story, I am trying to decide how they produce steel. I want steel to be an important part of the culture, but a thing that is in limited supply. I also do not want there to be a large amount of resources committeded to mining or processing iron ore for steel. So does anyone have any real world ideas explaining how the people can produce steel without using underground mining operations, large processing facilities, and without raping the land?All help and ideas are appreciated

- Well, steel is just modified iron, so you're going to have to start with acquiring the iron first. For that, you're most likely going to be using some sort of underground mining somewhere - either they do that themselves, or they purchase the iron elsewhere. Assuming you're not dealing with meteoric iron (which is possible, but pretty uncommon), or iron sands (not likely in a woodland area), then unless you're dealing with a rocky outcropping with iron veins out in the open, I'm pretty sure there needs to be somebody doing some digging. That said, it doesn't need to be a full raping of the land scenario. A couple of minor mines, some small-scale smelting operations, and somebody knowing the secret of making steel, and it could give you small amounts of steel without making an ecological disaster.

- Q: How are steel coils inspected for coil weight accuracy after processing?

- Steel coils are typically inspected for coil weight accuracy after processing by using weighing scales or load cells that are capable of accurately measuring the weight of the coil. The coil is placed on the scale or load cell, and the weight is compared to the target weight specified for that particular coil.

- Q: How are steel coils cleaned?

- Steel coils are typically cleaned using a combination of chemical and mechanical processes. The coils are first treated with a degreasing agent to remove any oil or grease present on the surface. Then, high-pressure water jets or brushes are used to scrub away any remaining dirt or contaminants. The coils may also undergo a rinsing process to ensure all cleaning agents are removed. Additionally, some manufacturers may use acid cleaning or pickling techniques to remove scale or rust from the surface of the coils.

- Q: What is the role of steel coils in the production of appliances?

- Steel coils play a crucial role in the production of appliances as they serve as the primary material for constructing the outer bodies, frames, and internal components of various appliances. The coils are formed into desired shapes and sizes, ensuring durability, stability, and strength of the appliances. Additionally, the steel coils enable efficient heat transfer, enhancing the performance and longevity of appliances such as refrigerators, stoves, and washing machines.

- Q: How is steel different than iron?How many different kinds of steel are there?What type is the strongest?Which type is the weakest?

- As first answer says, if you look at the number of commercial steel alloys available and consider that any given alloy can be heat treated to a wide range of physical properties, there are thousands and thousands of potential combinations. Technically, steel is an alloy of Fe and C but there are Fe-C alloys that are called cast irons, not steel, and... there are lots of alloy steels which have significant amounts of other elements added like Cr, Ni, Nb, V, Mo, etc. Fe alloys that have a lot of Cr and or Ni added are called stainless steels and there are dozens of them and many of them can be heat treated to produce a wide range of properties. As far as the strongest or the weakest, you have to get really specific about exactly what you mean because some steels are designed for room temperature properties, some are designed for elevated temperature properties, some for static loads, some for impact loads, some for wear resistance, etc, etc.. Steels make up the largest family of metal alloys (by weight and by volume) that humans use. There are a number of reasons for this but the big reasons include: 1) there is a LOT of iron on earth 2) it is relatively cheap to produce 3) you can easily change the physical properties over a every wide range. As an example... you can take a piece of steel that is so brittle it will shatter if you drop it on the floor and heat treat it so you can bend it like a pretzel without cracking and then heat treat it again to make it very strong and tough (resistant to fracture).

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: How are steel coils used in the manufacturing of railway equipment?

- The strength, durability, and versatility of steel coils are crucial factors in their importance in the manufacturing of railway equipment. These coils, typically made from high-quality steel, are extensively used in various applications throughout the railway industry. A primary application of steel coils in the manufacturing of railway equipment is the production of train tracks. By rolling and shaping steel coils into long, continuous rails, the foundation of railway tracks is formed. This allows the tracks to withstand heavy loads, constant train traffic, and harsh weather conditions, thanks to the coils' strength and durability. Moreover, the uniformity and consistency of steel coils ensure smooth and safe train operations. Additionally, steel coils are utilized in the manufacturing of railway wagons and carriages. These coils are shaped into various components, such as the framework, body panels, and structural supports of the wagons. The robustness of steel coils guarantees the structural integrity of the wagons, enabling them to carry heavy cargo and endure the hardships of railway transportation. Furthermore, steel coils find use in the fabrication of various railway equipment accessories, including couplings, brake systems, and suspension components. These coils are shaped and sized precisely to meet the specific requirements of each accessory. The strength and resilience of steel coils make them ideal for these critical parts, ensuring the efficient and safe operation of railway equipment. In conclusion, the role of steel coils in the manufacturing of railway equipment is vital. Their strength, durability, and versatility make them an essential material for constructing train tracks, wagons, carriages, and various accessories. The use of steel coils guarantees the safety, reliability, and longevity of railway equipment, making them an integral part of the railway industry.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- I'm afraid you have opened a can o'worms. Aluminum as a material is roughly 1/2 the weight of steel. Aluminum as a material is also roughly 1/3 the strength of steel. his means you need 3 times more aluminum to make a frame as strong as steel which makes the aluminum frame 25% heavier. That being said, well designed and more expensive aluminum frames can easily weigh less than low zoot steel. Buying a cheap bike with an aluminum frame will ALWAYS weigh more than a middle of the road bike with a steel frame. ...and THAT being said, high end steel can easily weigh less than a high quality aluminum frame... note we are talking frames in the $2000 range- just for the frame. So, based on your explanation and attendant budget of the bikes you are considering, buy the steel bike. You won't be losing or gaining anything... except saving money.

Send your message to us

PPGI Color Coated Sheet/Color Coated Steel Coil/Cold Rolled/PE

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords