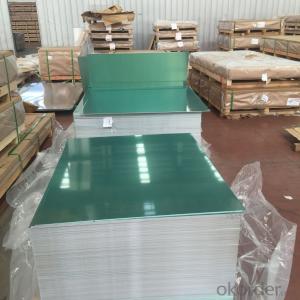

Backsplash Aluminum Sheets - Coated Aluminum Coil AA5074-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q: Can the aluminum sheets be used for manufacturing electronic heat sinks?

- Yes, aluminum sheets can be used for manufacturing electronic heat sinks. Aluminum is a popular choice for heat sink material due to its excellent thermal conductivity and lightweight properties. It efficiently transfers heat away from electronic components, helping to dissipate and manage heat generated during operation. Aluminum sheets can be easily formed and shaped into the desired heat sink design, providing effective cooling for electronic devices.

- Q: Are aluminum sheets suitable for food preparation surfaces?

- Yes, aluminum sheets are suitable for food preparation surfaces. Aluminum is a lightweight and durable material that is commonly used in the food industry. It is non-toxic, non-reactive, and does not release any harmful chemicals when it comes into contact with food. Aluminum sheets are also easy to clean and maintain, making them a popular choice for food preparation surfaces in both commercial kitchens and home kitchens. Additionally, aluminum has excellent heat conductivity, allowing for even cooking and baking. However, it is important to note that aluminum can react with acidic or salty foods, causing a metallic taste. To prevent this, it is recommended to use a layer of parchment paper or silicone baking mat as a barrier between the aluminum sheet and the food.

- Q: Is it possible to construct furniture using aluminum sheets?

- <p>Yes, you can use aluminum sheets to make furniture. Aluminum is a lightweight, durable, and corrosion-resistant material that is often used in modern furniture design. It can be easily shaped and welded, making it suitable for a variety of furniture pieces such as tables, chairs, and shelving. However, it's important to consider the design and structural integrity, as well as the finish and comfort, when creating furniture with aluminum. It's also advisable to use appropriate tools and techniques to ensure safety and quality in the construction process.</p>

- Q: Can aluminum sheets be used for battery enclosures?

- Indeed, battery enclosures can utilize aluminum sheets. Aluminum proves to be a highly favored material for battery enclosures owing to its remarkable properties. Its lightweight nature, resistance to corrosion, and commendable conductivity render it an appropriate choice for safeguarding batteries and guaranteeing their optimal functionality. Furthermore, the exceptional strength-to-weight ratio of aluminum permits the creation of robust yet lightweight enclosures, making it an ideal selection for diverse battery applications. Moreover, the recyclability of aluminum adds to its appeal as an eco-friendly alternative. In conclusion, aluminum sheets serve as a feasible and frequently employed material for battery enclosures.

- Q: Can aluminum sheets be used for chemical pumps?

- In certain applications, aluminum sheets can serve as a viable option for chemical pumps. Due to its lightweight nature and corrosion-resistant properties, aluminum proves to be a suitable material for handling a variety of chemicals. However, it is crucial to carefully consider the specific chemical being pumped and its compatibility with aluminum. It is possible for some aggressive or highly corrosive chemicals to react with aluminum, which could result in damage or contamination. In situations like these, it may be more appropriate to explore alternative materials such as stainless steel or plastic. Furthermore, it is essential to take into account the pump's design and construction in order to ensure proper sealing and protection against leaks or spills. For a specific application, it is advisable to seek guidance from a chemical engineer or an expert in the field to assess the compatibility and feasibility of employing aluminum sheets for chemical pumps.

- Q: Are aluminum sheets suitable for medical equipment?

- Yes, aluminum sheets are suitable for medical equipment. Aluminum is a lightweight metal that offers excellent durability and corrosion resistance, making it a popular choice for medical equipment manufacturing. It is used in various medical devices such as surgical instruments, diagnostic equipment, and patient monitoring systems. Aluminum sheets are easy to shape and form, allowing for the fabrication of intricate medical equipment designs. Additionally, aluminum is non-toxic and non-magnetic, which are important properties in medical settings. Its ability to withstand sterilization processes such as autoclaving further enhances its suitability for medical equipment. Overall, aluminum sheets are a reliable and versatile material for the production of medical equipment.

- Q: How do aluminum sheets perform in terms of thermal conductivity?

- Known for their excellent thermal conductivity, aluminum sheets are highly efficient in transferring heat due to having one of the highest thermal conductivity among common metals. This quality enables aluminum sheets to rapidly absorb and distribute heat, making them ideal for situations where heat needs to be dissipated or transferred quickly. Furthermore, their high thermal conductivity guarantees even heat distribution across the surface, reducing hot spots and improving overall heat transfer efficiency. As a result, aluminum sheets are widely acknowledged for their exceptional thermal conductivity, making them a favored option in industries such as automotive, aerospace, and electronics.

- Q: What are the different types of coatings applied to aluminum sheet?

- There are several types of coatings that can be applied to aluminum sheets. Some common ones include anodizing, powder coating, and organic coatings. Anodizing involves creating an oxide layer on the surface of the aluminum, providing corrosion resistance and enhancing durability. Powder coating involves applying a dry powder to the aluminum surface and then curing it to create a protective and decorative layer. Organic coatings, such as paints or lacquers, can be applied to aluminum sheets to provide color, protection, and aesthetic appeal.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: what were the cinergy field (riverfront stadium, cincinnati, oh) seats made of? were they metal or aluminum? i know they were silver under the red paint...

- Yes, they were. Aluminum IS a metal. Aluminium is a soft, durable, lightweight, ductile and malleable metal with appearance ranging from silvery to dull gray

Send your message to us

Backsplash Aluminum Sheets - Coated Aluminum Coil AA5074-H16, 0.62mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords