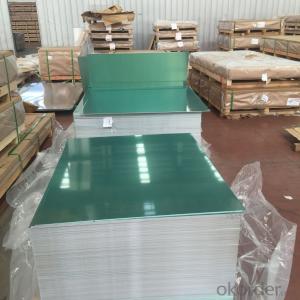

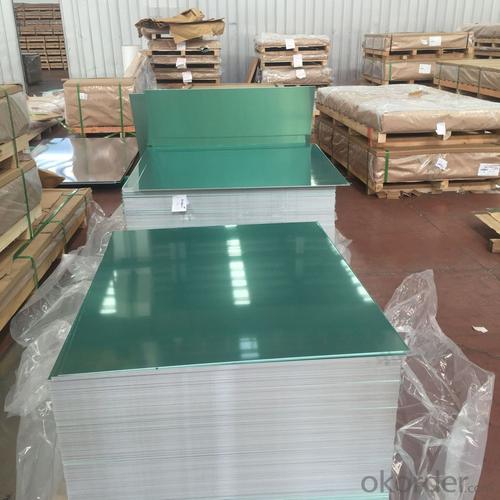

Aluminum Sheets - Coated Aluminium Coil AA3150-H16, 0.92mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

AA1050 C.C Mill Finished Aluminum Circles used for Cookware is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

AA1050 C.C Mill Finished Aluminum Circles used for Cookware is one semi-finished aluminium material. This strip can be rolled down to aluminium foil.The final thickess can be 5-20 microns. Aluminium foil is soft, ductile and with a silver-white luster which can be widely used in a large scare of fields.

Characteristic:

1)Excellent weather-proof durability

2)Anti-ultraviolet

3)High erosion resistance

4)Stable color and gloss

5)Good mechanical processing performance

6)Abrasion resistance

7)Anti-impact

8)High flexibility

- Q: Are the aluminum sheets suitable for welding?

- Aluminum sheets can indeed be welded. Welding aluminum is a popular choice because of its lightweight nature, high strength-to-weight ratio, and resistance to corrosion. Nevertheless, it is crucial to acknowledge that welding aluminum necessitates specific techniques and considerations that differ from those used with other metals. Aluminum possesses a lower melting point and higher thermal conductivity, making it more challenging to weld when compared to steel or other metals. For this reason, specialized welding processes like Tungsten Inert Gas (TIG) welding or Metal Inert Gas (MIG) welding with a spool gun are frequently employed for aluminum welding. Moreover, proper cleaning and preparation of the aluminum surface, along with the utilization of appropriate filler materials, are essential for achieving strong and enduring welds. In conclusion, by utilizing the appropriate equipment, techniques, and expertise, it is possible to successfully weld aluminum sheets and create various structures and components.

- Q: This question asks for precautions or methods to protect aluminum sheets from damage during the installation process.

- <p>To ensure that the installation process does not damage aluminum sheets, follow these steps: Use protective gloves to avoid scratches from hand oils or dirt. Employ non-marring tools to prevent any indentations or marks. Handle the sheets carefully to avoid bending or denting. Keep the surface clean and dry to prevent any chemical reactions or stains. Use appropriate support structures to distribute weight evenly and prevent warping. Always follow the manufacturer's guidelines for installation to avoid any improper handling that could lead to damage. Regularly inspect the sheets for any signs of damage during the installation process and address any issues promptly.</p>

- Q: How does the surface roughness affect the adhesion of coatings on aluminum sheet?

- Surface roughness plays a crucial role in the adhesion of coatings on aluminum sheet. The level of roughness on the surface of the sheet directly impacts the mechanical interlocking between the coating and the substrate, which is essential for strong adhesion. When the surface of the aluminum sheet is smooth, there is limited contact area between the coating and the substrate, resulting in weak adhesion. On the other hand, a rough surface provides more contact points, increasing the interlocking between the coating and the aluminum sheet, leading to improved adhesion strength. Additionally, a rough surface promotes better wetting of the coating material on the aluminum sheet. This means that the coating material can spread more easily over the surface, filling in any gaps or crevices, and creating a more uniform and continuous coating. This improved wetting contributes to enhanced adhesion. Furthermore, a rough surface can also increase the overall surface area of the aluminum sheet. A larger surface area means that there is more available space for the coating material to adhere to, increasing the adhesion strength. It is important to note that there is an optimum level of roughness for achieving the best adhesion. If the surface is excessively rough, it may lead to incomplete coverage of the coating material or the formation of voids, reducing adhesion. Therefore, finding the right balance of roughness is crucial to ensure optimal adhesion of coatings on aluminum sheet.

- Q: Are the aluminum sheets suitable for manufacturing kitchen utensils?

- Yes, aluminum sheets are highly suitable for manufacturing kitchen utensils. Aluminum is a lightweight and durable material that offers excellent heat distribution properties. It is corrosion-resistant, making it ideal for contact with food and liquids. Additionally, aluminum is non-reactive, which means it does not leach any harmful substances into the food being cooked or stored. It is also easy to clean and maintain, making it a popular choice for kitchen utensils. Overall, aluminum sheets are a reliable and efficient option for manufacturing a wide range of kitchen utensils.

- Q: What are the different methods of joining aluminum sheet?

- Some of the different methods of joining aluminum sheet include welding, adhesive bonding, riveting, clinching, and mechanical fastening.

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: What is the typical thickness tolerance for aluminum sheets?

- The typical thickness tolerance for aluminum sheets can vary depending on the specific grade and manufacturing process, but it is generally around ±0.005 to ±0.01 inches.

- Q: How are aluminum sheets measured and specified?

- Aluminum sheets are typically measured and specified based on their thickness, width, and length. The thickness is commonly referred to as the gauge, and it is measured in inches or millimeters. The sheet's width and length are also specified in either inches or millimeters. To measure the thickness of an aluminum sheet, a gauge is used. The gauge is a standardized measurement tool that determines the sheet's thickness. The lower the gauge number, the thicker the sheet. For example, a 10-gauge aluminum sheet is thicker than a 16-gauge sheet. The width and length of an aluminum sheet are typically measured in inches or millimeters. The width refers to the horizontal measurement of the sheet, while the length refers to the vertical measurement. These dimensions are crucial in determining the sheet's size and suitability for specific applications. In addition to the gauge, width, and length, aluminum sheets may also be specified based on their alloy composition or temper. The alloy composition indicates the specific combination of metals present in the sheet, such as aluminum-magnesium, aluminum-zinc, or aluminum-copper alloys. The temper refers to the heat treatment process the sheet has undergone, which affects its mechanical properties, such as hardness and flexibility. Overall, aluminum sheets are measured and specified by their thickness (gauge), width, and length. These measurements, along with additional specifications like alloy composition and temper, help ensure the appropriate selection and use of aluminum sheets for various applications in industries such as construction, automotive, aerospace, and more.

- Q: Can aluminum sheets be used for insulation jackets?

- Yes, aluminum sheets can be used for insulation jackets. Aluminum has excellent thermal conductivity properties, which allows it to effectively reflect heat and prevent the transfer of thermal energy. This makes it an ideal material for insulation jackets, as it helps to maintain temperature control and minimize heat loss or gain. Additionally, aluminum sheets are lightweight, durable, and resistant to corrosion, making them a practical choice for insulation applications.

- Q: Can the aluminum sheets be used for manufacturing decorative trim?

- Indeed, the utilization of aluminum sheets is viable for the production of decorative trim. Being a versatile substance, aluminum is renowned for its lightweight nature, durability, and exceptional resistance to corrosion. It bestows the convenience of effortless shaping and molding into diverse decorative configurations and motifs. Furthermore, aluminum's aesthetic allure can be accentuated by applying coatings or paints of assorted hues. Consequently, aluminum sheets emerge as a highly favored option for fabricating decorative trim across a multitude of sectors, encompassing architecture, automotive, and interior design.

Send your message to us

Aluminum Sheets - Coated Aluminium Coil AA3150-H16, 0.92mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords