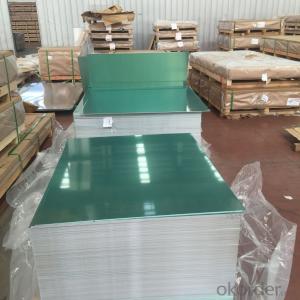

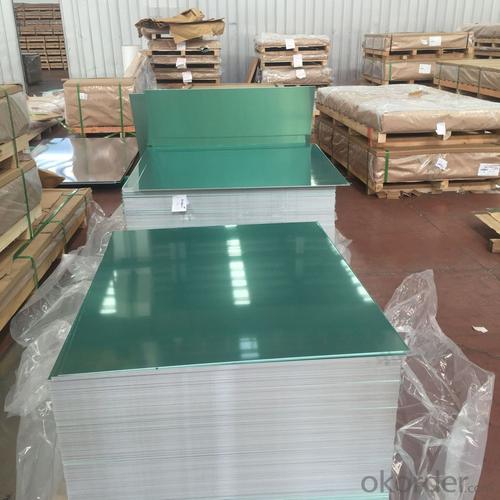

Aluminum Sheets Georgia - Coated Aluminium Coil AA100-H16, 0.72mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminum coils color coated are of a wide range of colors, which give wonderful appearance no matter in residential and commercial constructions or great exhibition centers.

Aluminum coils color coated have been widely used in the fields of construction and decoration, electronic applications, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

2.Main Features of the Aluminum Coils Colored Coated

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

4.Aluminum Coils Colored Coated Specification

Alloy AA1xxx,AA3xxx,AA5xxx

Temper H14,H16,H18,H22,H24,H26,H32,O/F

Thickness 0.03mm-3.0mm

Width 30mm-1700mm

Coating PE,PVDF,Epoxy

Painting Thickness Standard 16-25 Mic, max 40 Mic

Color According to RAL colors or customers' samples

Standard GB/T 17748-1999

- Q: Are the aluminum sheets suitable for manufacturing architectural roof systems?

- Indeed, architectural roof systems can be manufactured using aluminum sheets. Aluminum is widely favored as a roofing material due to its exceptional durability, lightweight composition, and resistance to corrosion. These remarkable attributes render it highly capable of enduring diverse weather conditions, such as strong winds, heavy rainfall, and snowfall. Moreover, aluminum can be easily manipulated and molded into various shapes, granting versatility in both design and installation. Furthermore, it is worth noting that aluminum is an eco-friendly choice, as it can be recycled. Ultimately, the utilization of aluminum sheets in the production of architectural roof systems presents a wide array of advantages and proves to be a suitable option for this purpose.

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a preferred material for fuel tanks due to its excellent properties such as lightweight, durability, corrosion resistance, and high strength-to-weight ratio. These properties make aluminum sheets highly suitable for manufacturing automotive fuel tanks as they provide fuel efficiency, reduce vehicle weight, and enhance overall performance. Moreover, aluminum can be easily formed and welded, allowing automotive manufacturers to create complex tank designs while maintaining structural integrity. Additionally, aluminum sheets have a low melting point, which facilitates the welding process during tank manufacturing. Overall, the use of aluminum sheets in the production of automotive fuel tanks is a reliable choice that meets safety standards and contributes to the efficiency and performance of vehicles.

- Q: Are the aluminum sheets suitable for manufacturing aircraft fuselages?

- Yes, aluminum sheets are suitable for manufacturing aircraft fuselages. Aluminum is widely used in the aerospace industry due to its excellent strength-to-weight ratio, corrosion resistance, and easy formability. It provides structural integrity while keeping the weight of the fuselage low, making it an ideal material choice for aircraft manufacturing.

- Q: I have heard that drinking from aluminum cans is bad for our health. However, I have learned that today's 'aluminum' cans are actually more like a plastic can due to all the coatings, etc. Do we really have any risks associated with regular cans?

- Aluminum is dangerous when you breath high levels from the air. There is no evidence that liquids stored in aluminum cans leach in enough aluminum to have any effect at all. Quite often these sorts of rumors/assertions start with that kind of kernel of truth. Remember though, chemistry is complex. A chemical that can kill you in one state/amount is pretty harmless in another. For example, hydrogen dioxide is deadly when taken in large amounts, but it is safe in the amounts we normally drink.

- Q: What are the different surface patterns available for aluminum sheets?

- Depending on the desired aesthetic and functional requirements, aluminum sheets can exhibit a range of surface patterns. Some commonly used patterns include: 1. Smooth Finish: This basic pattern offers a flat and polished appearance, ideal for applications that prioritize a clean and sleek look, such as architecture and interior design. 2. Stucco Embossed: Featuring a raised texture resembling stucco, this pattern enhances durability and slip resistance. It is suitable for surfaces like stair treads or ramps that require a non-slip surface. 3. Diamond Tread: This pattern consists of raised diamonds on the surface, providing superior traction and slip resistance. It is commonly used in applications where safety is a concern, such as vehicle running boards or industrial flooring. 4. Hammered Finish: Creating a textured appearance similar to hammered metal, this pattern adds visual interest and can be used to enhance the aesthetics of architectural elements, decorative panels, or furniture. 5. Brushed Finish: Also known as satin finish, this pattern is achieved by brushing the aluminum sheet in a linear direction. It creates a smooth and consistent texture, often used for decorative purposes in applications like signage, wall cladding, or kitchen appliances. 6. Perforated: In this pattern, the aluminum sheet is punctured with small holes or slots in a specific design or pattern. It allows for airflow, light transmission, and sound absorption, making it suitable for applications like ventilation systems, acoustic panels, or decorative screens. These examples illustrate the variety of surface patterns available for aluminum sheets. The choice of pattern depends on the intended use, desired appearance, and functional requirements of the application.

- Q: Are there any health risks associated with using aluminum sheets?

- There is ongoing debate and research regarding the potential health risks associated with using aluminum sheets. While aluminum is a common material used in various industries and products, it is important to consider certain factors. Exposure to high levels of aluminum, such as through inhalation or ingestion, has been linked to health issues. Studies suggest that aluminum exposure may be associated with neurological disorders, such as Alzheimer's disease or Parkinson's disease, as well as respiratory problems and bone disorders. However, it is important to note that these studies have not yet established a definitive causal relationship between aluminum and these health conditions. The primary concern with aluminum is its potential to leach into food or beverages when it comes into contact with acidic or salty substances. This leaching can occur during food preparation or storage, especially if using aluminum cookware or foil. Consuming high levels of aluminum through food or drink may pose health risks, particularly for individuals with kidney disease or those who have a higher susceptibility to aluminum toxicity. To mitigate potential health risks, it is recommended to avoid using aluminum cookware or foil when cooking or storing acidic or salty foods. Instead, consider using alternatives such as stainless steel, glass, or silicone. In conclusion, while there are concerns about the potential health risks associated with using aluminum sheets, more research is needed to establish a clear cause-and-effect relationship. It is prudent to minimize exposure to aluminum, especially through food and beverages, by adopting preventive measures and using alternative materials when appropriate. Consulting with health professionals and staying updated on the latest research can help individuals make informed decisions about using aluminum sheets and other aluminum products.

- Q: Are aluminum sheets suitable for signage applications?

- Indeed, signage applications can benefit from the use of aluminum sheets. Due to its lightweight nature and durability, aluminum proves to be an ideal material for outdoor signs that must endure diverse weather conditions. Its resistance to rust and corrosion guarantees the sign's longevity. Moreover, aluminum sheets can be effortlessly customized and shaped into various sizes, enabling the creation of versatile and imaginative signage options. Furthermore, aluminum serves as an exceptional material for digital printing, producing top-notch graphics and images. All in all, aluminum sheets present remarkable durability, versatility, and aesthetic allure, cementing their status as a favored choice for signage applications.

- Q: Can aluminum sheets be used for air ducts?

- Indeed, air ducts can utilize aluminum sheets. Aluminum, known for its lightweight and durable characteristics, is frequently employed in air ducts. Its resistance to corrosion renders it a suitable option for HVAC systems. Air ducts are often constructed using aluminum sheets due to their malleability, enabling easy bending and shaping to meet specific dimensions. Moreover, aluminum boasts commendable thermal conductivity, ensuring efficient heat transfer within the ducts. Ultimately, opting for aluminum sheets in air ducts proves to be a pragmatic and efficient decision.

- Q: How does the thickness tolerance of aluminum sheet affect its usability?

- The usability of aluminum sheet is greatly influenced by its thickness tolerance, which refers to the acceptable deviation from the specified thickness. This tolerance is typically expressed as a range or a plus/minus value. Having a tighter thickness tolerance guarantees that the aluminum sheet consistently meets the desired specifications. This is crucial in industries such as aerospace, automotive, and construction, where precise dimensions are necessary. Even a slight deviation in thickness can have a negative impact on the performance and functionality of the product. For example, in aircraft manufacturing, the thickness tolerance of aluminum sheets used for structural components is of utmost importance. A thin sheet could compromise the structural integrity, while a thicker sheet could add excess weight, affecting fuel efficiency. Similarly, in the automotive industry, precise thickness tolerance is vital to ensure compatibility and fitment of various components. On the other hand, a looser thickness tolerance may be acceptable in applications where precise dimensions are not as critical. For instance, in general fabrication, signage, or decorative purposes, a wider thickness tolerance may not significantly affect the usability or appearance of the aluminum sheet. Furthermore, manufacturing aluminum sheets with tighter thickness tolerances generally incurs higher costs due to increased precision and quality control measures. Therefore, the desired level of tolerance should be carefully balanced with the intended use and cost considerations. To conclude, the usability of aluminum sheet is directly influenced by its thickness tolerance, particularly in industries that require precise dimensions. Selecting the appropriate tolerance level is essential to ensure that the sheet meets the necessary specifications and maintains the desired performance and functionality of the final product.

- Q: I was looking at Audioque subs earlier and what is the difference between copper and aluminum coiled subs. do aluminum last longer or something?

- to maintain it common......Copper is better at removing or soaking up warmth than aluminum yet aluminum is better at dissipating it or doing away with it. i think it is why you spot aluminum CPU coolers with copper cores.

Send your message to us

Aluminum Sheets Georgia - Coated Aluminium Coil AA100-H16, 0.72mm Thickness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords