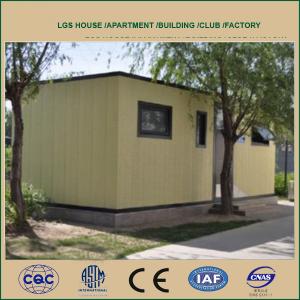

CNBM INTERNATIONAL LOW COST SMALL PREFABRICATED CONTAINER HOUSES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM INTERNATIONAL LOW COST SMALL PREFABRICATED CONTAINER HOUSES

CNBM INTERNATIONAL LOW COST SMALL PREFABRICATED CONTAINER HOUSES

Product description

1. Container house is a unit house with the size of 6055mm*2435mm*2740mm.

2. The container house adopts EPS, glass wool or rock wool as heat insulation material.

3. All the components are standard and prefabricated with the advantage of assembling and disassembling easily. Six skilled workers can finish three modular units in 8 hours.

4. 4sets of standard container house can be packed together to replace the shipping space of one 20ft container.

5. The container house can be linked freely at length, width and height through the linking kits for bigger structure and different layout.

6. Waterproof design of galvanized structure, fireproof and heat insulation of material ensure the house to resist heavy wind load of 0.6KN/m2and 8 degree seismic intensity.

7. The life span of the house is 20-25 years.

Characteristics

1. Cost Effectiveness

2. Chemical free, and lower waste

3. Easy to erect

4. Safety

5. Fireproof, termite free

6. Strong and durable – weatherproof, anti-seismic

7. Materials will not shrink, rot or warp

8. Pre-galvanized for rot and corrosion prevention

Benefits of factory built prefabricated houses and villas

| |

Very little maintenance | Reduce environmental pollution and save water |

Ease and speed of erection | Easily transportable |

Aesthetically pleasing | Buildings can be relocated |

Priced more economically than brick | Buildings can be designed by your choice

|

- Q: Have to know the holy spring Antwerp phenolic steel sandwich board how much money a square? I heard that the insulation effect is good, fire performance is also very good

- Phenolic insulation board a square 400 or so it Almost all of the price of phenolic need 50 points of oxygen was on fire, OKorder Zhongji machinery manufacturing phenolic insulation is the export, to the domestic sales a little less, you can order the next.

- Q: What are the thickness of the color steel sandwich board? Color steel sandwich panels: two layers of steel thickness of 0.6mm, the middle folder a layer of foam, a total thickness of several specifications?

- Color steel sandwich panel thickness generally have the following: 25mm 50mm 75mm 100mm 150mm 200mm which after the two kinds of thickness is generally used for cold storage. You said the foam (EPS) density of the points, generally: 4g 6g 8g 10g, Can be purchased according to their own needs!

- Q: The Development Trend of Color Steel Sandwich Board

- Rockock structure rock wool composite board (rock wool color steel sandwich panel) is characterized by: high strength: only fixed at both ends, no purlin system, single span up to 12m high fire: high fire rating, up to 4 hours fire resistance Durability: in line with the highest standards of durability in Europe, to maintain the design of the building properties Multi-function: set fire, thermal insulation, sound insulation in one beautiful: large span mirror flat, beautiful metal appearance, comparable to aluminum curtain wall flexibility: flexible design Diverse, installation Flexible installation: easy installation, shortening construction cycle Economy: saving purlins, reducing total building costs, reducing total cost of product through FM certification (indicating that the product or service has passed the highest standards of the United States and international testing)

- Q: What is the difference between the ecological board and the sandwich board? Which is used to decorate better, what is the price? What are the top ten brands of the two boards?

- The ecological board is made of natural mineral stone powder and natural fiber as the basic raw material, through the inorganic gel technology modification process, through the mold, natural curing molding for the environmental protection and energy saving new materials, which does not contain formaldehyde, toluene inorganic natural environmental performance, Combined with the surface of the natural texture and sustained and efficient negative oxygen ion release, to achieve its natural properties of green building materials. Sandwich panels, composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the polymer core insulation composition, easy to install, light and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor.

- Q: Bubble (EPS) color steel sandwich panels how to wear thread

- Of course, is the use of PVC flame retardant tube friends, huh, huh, I recommend that our company is doing foam sandwich panels, the general customers are doing this, I mainly recommend Oh,

- Q: Flour mill production workshop, steel frame, roof with glass wool cotton sandwich panel (veneer) whether it can,

- It is possible to use color steel

- Q: What are the advantages of polyurethane gluing wool sandwich panels?

- Polyurethane sandwich panel insulation good insulation, good overall stiffness, high bearing capacity, suitable for clean room, warehouse, commercial buildings, indoor and outdoor gymnasium, cold storage, indoor partitions and so on. Rock wool sandwich panels fire superior performance, sound-absorbing effect is significant, thermal insulation slightly inferior to polyurethane, but the price is cheaper than polyurethane, suitable for steel structure plant, simple activities of the roof or wall, air clean room ceiling and partition The

- Q: Foam sandwich board in line with the fire building requirements? There is no regulatory requirements in this area? I was in Jiangsu !! Thank you

- Suggestions on Optimum Selection of Composite Materials in Fire Scene and Their Use in Construction. ??????????????????????????????? Metal surface polystyrene foam sandwich panels in the application of the most widely used, usually with the roof panels, partition panels, ceiling panels, polystyrene foam in the fire and high temperature melting, so the first case of the performance of the bubble Melt shrinkage for the plastic melt adhesion on the metal surface, the plate lost support and integrity, followed by the performance of combustion and smoke, used as a partition board and ceiling panels will quickly collapse, thus affecting the evacuation, resulting in personnel Casualties, used as a roof will be hanging on the steel beam and other roof load bearing components, as long as the overall steel roof trusses because of fire deformation and loss of support, will not collapse. Metal surface polyurethane sandwich panels in the case of fire mainly in the sandwich layer of smoldering and smoke, unburned parts will not be due to the rapid loss of high temperature support. Polystyrene foam composites coated with non-combustible materials such as concrete mortar will be lost in the case of fire. The support force collapses, flips, accelerates the spread of fire along the facade. ???????????????????????????????????????? Composite materials in the construction of the actual selection should take into account all aspects of the requirements, according to the actual needs of the scientific selection.

- Q: Sandwich panel sandwich board classification

- According to the functional requirements of Party A or plant to choose the type of roof sandwich panels, such as you want to set fire, then generally use rock wool; insulation, then with the composite board, as is the general insulation or important insulation (for cold storage) According to his weight. As for the upper and lower board general Party has a request, if the party did not ask, it is like a routine

- Q: Polyurethane insulation board and polyurethane color steel sandwich panels What is the difference

- Different materials, content and form is completely different

Send your message to us

CNBM INTERNATIONAL LOW COST SMALL PREFABRICATED CONTAINER HOUSES

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords