Pre-painted Steel Coil for Roof of Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Pre-painted Galvanized Steel Description:

With GI as base metal, after pretreatment and liquid dope with several layers of color, then after firing and cooling, finally the late steel is called pre-painted galvanized steel which is good capable of decoration, molding, corrosion resistance.

2.Main Features of Pre-painted Galvanized Steel:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

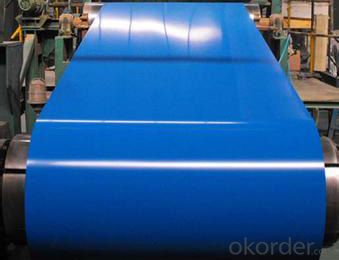

3. Pre-painted Galvanized Steel Images

4. Pre-painted Galvanized Steel Specification

Standard: JIS G3312 ASTM 755M, EN10169

Grade: CGCC,CS, DX51D

Thickness: 0.16mm~1.5mm,0.16-1.5mm

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Steel

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

- Q: The current market price is how much money a square meter?

- Polystyrene is a good point of its own do not have to consider the high temperature side of the polystyrene composite board cost-effective relatively high cost

- Q: Build a color steel sandwich panel production plant how much money

- The general machine price of 25 million or so, the venue costs plus how much raw materials you need, you can run the general about 100 million, but the funds to return to the fast, can not have too much debt.

- Q: 50mm thick color steel rock wool sandwich board price is generally how much

- 50 thick rock wool color plate prices according to the rock wool core material and the thickness of the panel thickness and quality parameters are closely related! But the general quality of a little bit almost 50 thick rock wool color plate price of about 40 yuan / m or so Medium quality 50 thick color steel rock wool sandwich panel price of about 55 yuan / m or so Good quality 50 thick color steel rock wool sandwich board price of about 65 yuan / m But the above price information is estimated, the specific price or suggest that you consult a professional Hongxin source belongs to the Shandong region of a 50-thick rock color steel plate

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Polyurethane foam can only achieve B1 flame retardant, the system's fire resistance by the two sides of the composite material fire resistance decision.

- Q: Color steel sandwich panels can be used for many years

- If it is GB double-sided 0.45MM Baosteel foam 16KG / M, then 25 years certainly no problem

- Q: I have a small shed, want to use sandwich panels construction, how can the summer 40 degrees with air conditioning to save power

- Wall plug a layer of sandwich panels no problem, but the window and sandwich panels to achieve the same insulation effect is difficult!

- Q: Sandwich board is used to do what ah ??

- Should be "sandwich board" was right. Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Sandwich panels for large industrial plants, warehouses, gymnasiums, supermarkets, hospitals, cold storage, activities, building plus layer, clean workshop and the need to heat insulation fire places.

- Q: With a foam sandwich board made a 72 flat house, the cheapest how much money

- It depends on how high your house, the color plate is calculated by the board area, calculate the material about 90 or so per square

- Q: How do you make a curved shape on a sandwich panel?

- You can open a lot of slots on the board, the depth of the slot than the thin about two millimeters, each slot spacing to stay three millimeters. The whole board to open such a slot, so that you can make a curved

Send your message to us

Pre-painted Steel Coil for Roof of Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50000 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords