Rock wool sandwich panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Rock Wool Sandwich Panel

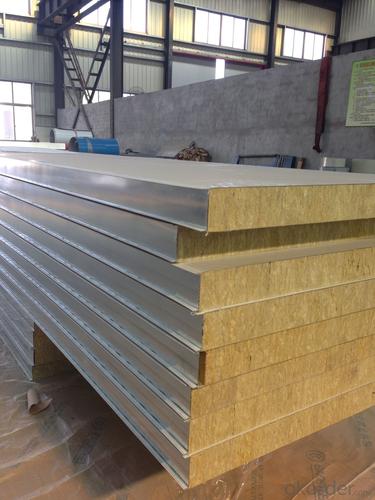

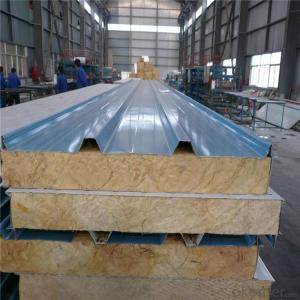

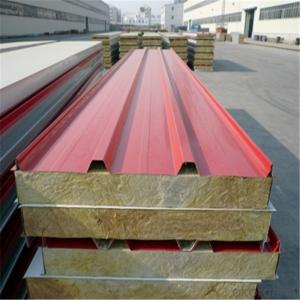

Structure | 1.)Steel sheet for both the surface 2.)Rock wool for the core material 3.)Steel cover for both sides |

Steel Sheet Thickness | 0. 3~0.6mm,PPGI |

Panel thickness | 50mm~200mm,common thickness is 50mm,75mm,100mm |

Effective width | 1.) 950mm--- Corrugated Roof Panle 2.) 950 / 1150mm---Wall or Ceiling Panel |

Length | Custom, less than 11.8m |

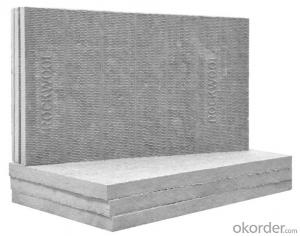

Rock wool density | 80~300kg/m3 , Normal is 120kg/m3 |

Color | Regular is White/Red/Blue, also can be Custom |

Fire proof | Can meet the A1 Grade |

Parts | Steel cover for easy to connect one piece to another, easy to assemble Film covering to protect the steel of panels |

lifetime | 20~25 years |

Character | Light in weight, excellent heat insulation, fire-proof and waterproof, Anti-bending and stress , environmental and energy-saving |

Use | for all kinds of prefabricated buildings’(warehouse, workshop, garage etc.) roof and wall for existing buildings, can be exterior protected construction or bearing structure |

Packing | Flat packing in shipping Container or according to your demands |

Features:

1)Weatherability

Covered with painted steel sheet, rock wool sandwich panel has particular weather resistance and durability. Our products are durable and can resist the effects of rain, snow, wind, frost and or other bad weather.

2)Excellent insulation and Fireproofing performance

Rock wool incorporated into the panel design shall provide a sufficient thermal break to ensure non-conductivity of temperature between surfaces. It is ideal material for construction in both tropical and frigid countries, it will bring you a comfortable and safe habitation. The core of new self-insulation composite wall material is A class incombustible rock wool.

3)High supporting capability

Individual panel size and configuration is dependent upon project design requirements. The integrated galvanized antirust steel studs for strength is pre-inserted in the wall, and strength of our system depends on the specification and space of steel studs.

4)Installing easily and quickly

It is easy to install with some bonding glue. Our building systems create a single, one-piece corner or T-shaped connecting sections, eliminating the difficult problem of joints between two walls. Several workers are enough for whole construction, and only need 1/4 time of traditional construction.

5)Excellent strength and durability

Our building systems is customized to the exact architectural drawings, design and specifications and can also be used for almost all kinds of foundation wall system as well as structural floor, wall and roof systems. Formed steel studs shall comprise the integral framework of all panels and sections. It provides lasting strength. Our system and panels shall meet or exceed all code requirements. The houses can be installed without other frame and make the building durable enough.

6)Wide applications

Our building systems could be widely used in exterior wall and partition of villas, residential houses, workshops, cold storages, security lodges, civil engineering, mobile toilets, rubbish centers, transformer substations, sentry boxes and other prefabricated houses.

7)Low Cost-- Industry and trade integration

We have our own factory with several production lines manufacturing the panels and sell them through our own trading company. So we can give you the most competitive price and control the delivery time for your benefits!

- Q: Is polystyrene sandwich board flammable?

- Conventional flat polystyrene polystyrene sandwich panels are non-flame retardant, there is a Hongxin source flame retardant polystyrene sandwich panels, but relatively less flame retardant effect such as rock wool and other core material sandwich panels , And now fire requirements are not allowed to use polystyrene sandwich panels

- Q: Purification workshop manual sandwich board how much money to install a square can do

- You search under the Suzhou Jinjiaba town and Zhenze town side of the factory, cheaper.

- Q: Activity board room C-shaped steel and Caigang sandwich panel is how to connect the seal?

- This is the plug without sealing if you need to seal and then plug the sealant on the line

- Q: 75mm thick color steel sandwich core layer thickness how much. I covered the company's core layer thickness of 50 corrugations height of 35 pairs?

- Generally speaking, 75mm thick sandwich panel sandwich layer thickness is 75mm, does not include the height of corrugated

- Q: Is the foam sandwich plate formaldehyde?

- Use to enjoy the formaldehyde detector under the test to know whether it contains formaldehyde, and large screen real-time display, triple alarm preset function, Portable compact hand.

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: Sandwich board is 50,75,100,150, color steel thickness, casually one can.

- You do not know the thickness of the color plate is not the same as the core material is not the same as the thickness of the core material is not the same as you can say that

- Q: Color steel sandwich board where the best quality?

- To see where you are, too far away from the good cost is also high, the best distance from the nearest, I was Xuzhou people, I think before the company in the Pepsi Steel made Bo Sige plate is very good,

- Q: Is the factory wall with a sandwich board fire clearance?

- The first look at the factory declaration materials in the building level. The second depends on the material you use sandwich panels. (Generally Caigang sandwich rock wool no problem, glass wool depends on the design requirements of the building).

- Q: Polyurethane insulation board and polyurethane color steel sandwich panels What is the difference

- Different materials, content and form is completely different

Send your message to us

Rock wool sandwich panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords