WBP Melamine Glue Poplar Core Film Faced Plywood with 19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details:

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Brand Name: buildplex

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Plywood Type: Other

· Size: 1220x2440mm,1250x2500mm

· Thickness: 18mm,9mm 12mm, 15mm,21mm

· Core: poplar

· Glue: WBP

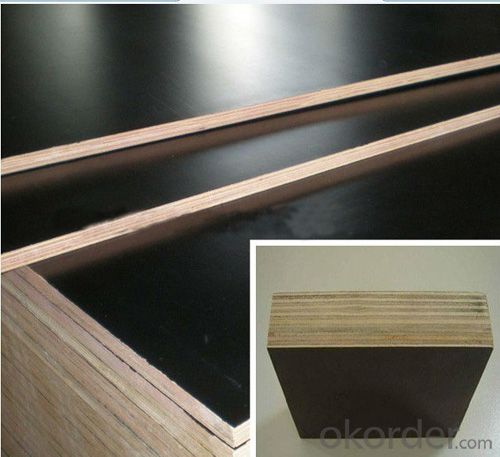

· Cycle life: 2-4 times uses

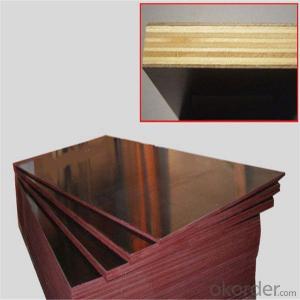

· Film: brown,black,red

· Moisture: below 16%

Packaging & Delivery:

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

Delivery Detail: | within 20 days after receiving LC or deposit |

Product Specification:

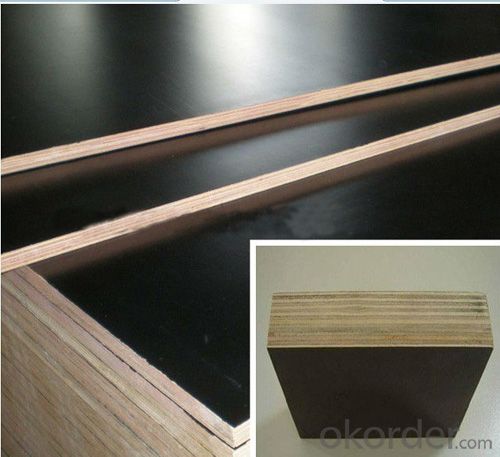

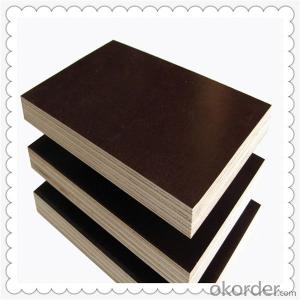

Product Name | Film faced plywood |

F/B | Black film, brown film, red film |

Grade | First grade |

Core | poplar |

Glue | WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, 100% irrevocable LC |

Delivery Time | Within 20 days after order confirmed |

Supply Capacity | 5000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique Credit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result | |

1 | Moisture content | % | EN322 | 10 | Check out | |

2 | Density | Kg/m3 | EN322 | 530 | Check out | |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.27 Min:0.6 | Check out |

Damage rate | % | GB/T17656-1999 | 60% | |||

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 5800 | Check out |

Lateral | 4500 | |||||

5 | Bending strength(N/mm) | Longitudinal | 40.1 | Check out | ||

Lateral | 33.2 | |||||

6 | Cycle Life | About 2-4 repeated using times according projects by formwork application | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

Our Mission: provide customers with high quality and service!

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate is iron plate, and Caigang sandwich plate is the middle of the core sandwich, such as: foam color steel sandwich panels, etc.

- Q: Purification workshop manual sandwich board how much money to install a square can do

- You search under the Suzhou Jinjiaba town and Zhenze town side of the factory, cheaper.

- Q: 100 thick 960 color steel sandwich board how much money one meter? What is the bulk density?

- This is not necessarily normal 8 kg, 10 kg

- Q: What are the sandwich panels used in steel roofs? How much is the price?

- There are two kinds of steel panels used in steel roofs, one is called sandwich panels, that is, the factory has been the roof of the inner and outer color plate and the middle of the insulation layer composite; the other is called composite board , That is, the roof of the site at the site will be inside and outside the color plate and the middle of the insulation layer installed together. The advantage of the sandwich panel is because the factory has been compounded, so the site is quick and easy to install; the shortcomings are limited by the transport, the length is generally within 12 meters, the length of the slope is greater than the roof of the hidden water leakage. Because of its different insulation materials, one for the polystyrene sandwich panels, commonly known as foam board, the other for the polyurethane sandwich panels. Specifications are generally 50mm, 75mm, 100mm thick, the main use of the South 50mm thick board, the price according to the origin of color plate inside and outside the different, different thickness will be a difference to conventional 50mm thick, inside and outside the color plate for the OKorder Baosteel 0.5mm board For example, the unit price of about 65 yuan / m2, the land prices will be different Above the thickness of the board for each additional 15 yuan / m2. The advantages of composite panels due to the production in the field compound, you can ensure that the slope of a long slope, there is no leakage of hidden dangers; the disadvantage is that the installation of a little trouble. Thickness and price of the same as above

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: Sandwich board ceiling how to build? What's the utility?

- Hello, as far as I know: the general price of a square in twenty or thirty dollars or so look. Sandwich panels are widely used in industrial non-load-bearing walls and civil buildings, roofs, ceilings and housing wall panels, machinery, electronics, chemical industry, insulation, , Medicine, biology, food, health and other clean room partition, ceiling, etc. for a single combination of Caigang sandwich panels. The sandwich plate molded part is a cured composition of a metal plate (or other material panel) made of two layers and a polymer formed by foaming directly in the middle of the panel and forming the insulating core. The above prices are network reference, the specific price to the actual purchase. Hope to help you

- Q: What is eps insulation corrugated sandwich panels

- EPS Chinese name is made of polystyrene, polystyrene resin is the third largest variety, the relative density of 1.05 ~ 1.06, heated to 90 ~ 110 degrees, the volume can be expanded 5 to 50 times, is a heat, Noise, shock, water, acid and other properties of foam.

- Q: Introduction of foam sandwich panels

- Foam sandwich panels beautiful appearance, bright color, the overall effect is good, it sets load, insulation, waterproof in one, and no secondary decoration, is a wide range of uses, especially in the construction site for temporary facilities such as office, Wall, etc., but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be installed in the removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Will be indispensable for new lightweight building materials.

- Q: What is the difference between a steel structure installation sandwich panel and a field composite board approach?

- Color steel, also known as: color pressure tile, is the use of color coated steel plate, the cold bending into a variety of wave-type pressure plate, it applies to industrial and civil construction, warehouses, special buildings, large span steel housing Roof, wall and interior and exterior decoration, with light, high strength, rich color, convenient construction, earthquake, fire, rain, long life, free.

- Q: Are thermocol roof insulation boards or thermocole sandwich concrete bricks durable?

- I typed in thermocol and this is what it gave me. Hope it helps. polystyrene (p?l'ēstī`rēn), widely used plastic plastic, any organic material with the ability to flow into a desired shape when heat and pressure are applied to it and to retain the shape when they are withdrawn. Polystyrene is a colorless, transparent thermoplastic that softens slightly above 100°C; (212°F;) and becomes a viscous liquid at around 185°C; (365°F;). It is resistant to acids, alkalies, oils, and alcohols. It is produced either as a solid or as a foamed plastic marketed under the trade name Styrofoam. Its many uses include electrical and thermal insulation, translucent window panels, storage-battery cases, and toilet articles

Send your message to us

WBP Melamine Glue Poplar Core Film Faced Plywood with 19mm Thickness

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords