aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum honeycomb panel:

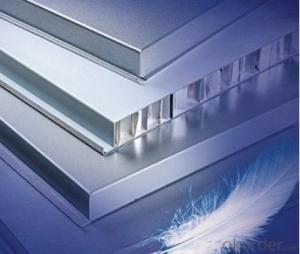

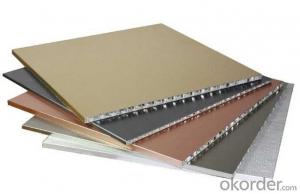

Aluminum honeycomb panels using the "sandwich" structure, surface treatment of aluminum alloy sheet fluorocarbon roll, the middle is in line with the National Aeronautics and aluminum honeycomb core standards. From Germany to introduce the use of sandwich boards for the production process --- continuous hot technology, chip technology hot, room temperature composite technology, specializing in the production of such products. So that the product has a more pronounced excellent properties, are widely used in building walls and interior decoration。

Material:

The main panel 3003 h24 series of magnesium alloy or magnesium alloy 5052 h24 series aluminum base material, 0.7 1.0 mm fluorocarbon roller plate thickness of the panel, the plate thickness of 0.5 1.0 mm, general choice 10 to 25 mm thickness. Use 3003 h24 hexagonal honeycomb core sandwich core material, the thickness of aluminum foil 0.04 0.06 mm, can fully meet the design and production needs of custom aluminum honeycomb core.

Aluminum honeycomb panel features:

★ high strength.

★ stiffness.

★ light weight.

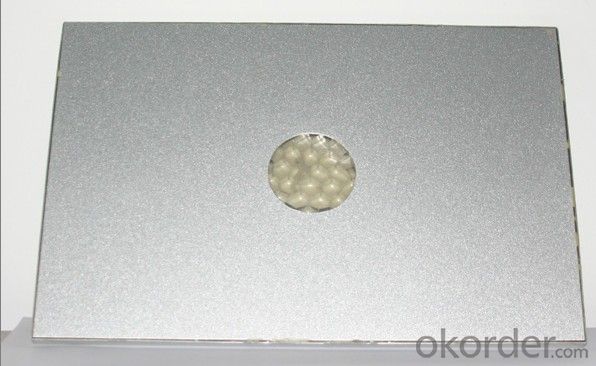

★ good surface flatness.

★ fire performance is good: B1 level.

★ noise effects: air sound insulation 29dB.

★ good insulation: thermal conductivity 0.1613W / (m.k).

★ surface using paint roller coating technology: 70% of fluorocarbon paint, weathering wall, with self-cleaning capability.

★ aluminum honeycomb panels have good temperature resistance: when used in different geographical environment -40 ℃ to + 80 ℃, according to special requirements, can reach 100 ℃.

★ environmental protection, aluminum honeycomb panels without separation or classification can be completely recycled.

Aluminum h oneycomb panel product application areas:

Buildings and structures: roofs, facades and wall cladding, ceiling / partition / door, interior {walls, floors}

Elevator: bridge car negatives, siding, roof

Exhibition, display: exhibitions, display card production, store decoration

Transportation: commercial vehicles [envelope, car bottom], ship bilge {version} bulkhead, rail, rail vehicles {negatives, siding} public, special transport vehicles {container volume, transport trough}, aircraft industry

Aluminum honeycomb Specifications:

Thickness: 6mm-560mm

Al thick: 0.5-2.5mm

Width: 800 ~ 1700mm

Length: any length

Color: do special color

Core: aluminum honeycomb core 3003H19 or 5052

Coating: fluorocarbon coating

Workshop Photos

- Q: Roof 100mmEPS sandwich board how much money a square

- 100MM look at the thickness of steel is generally around 60-85. Need to be able to stand letter me, my Jiangsu

- Q: Purification workshop manual sandwich board how much money to install a square can do

- Artificial is generally 18 - 30 side of the doors and windows in addition to the general one plus a window plus 80--100 yuan

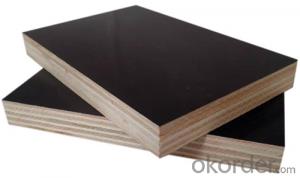

- Q: What is the difference between nine and sandwich panels?

- The usual nine PCT board is a multi-layer board, a layer of layers together, hardness, flatness is better, you can do floor floor. Sandwich panels refers to woodworking board, and some places called Daixin board, do furniture with much more.

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: How is the ceiling of the residential sandwich panel under the roof?

- Method is to use the form of flat ceiling, the top of the pipeline blocked in the ceiling, the top can be embedded in the downlight or built-in fluorescent lamp, so that the top of the decoration after the formation of two levels, will not produce a sense of depression. Shaped ceiling with a cloud-like wave or irregular arc, generally not more than one-third of the overall top area, more or less than this ratio, it is difficult to achieve good results.

- Q: Polyurethane sandwich panel system of fire resistance, the general can be how much you like 100 thick

- Internal use of B1 grade polyurethane foam core material, fire resistance and panel material. For example, both sides of the use of cement-type plate and other composite, you can achieve composite A-class. While the use of color composite plate on both sides of the sandwich panel can not achieve composite A-class.

- Q: What is the size of the sandwich panel?

- First, the roof or the wall Second, cross-section parameters Three, two-sided panel material, thickness, origin, coating; intermediate core material, thickness, density

- Q: Introduction of foam sandwich panels

- Foam sandwich panels beautiful appearance, bright color, the overall effect is good, it sets load, insulation, waterproof in one, and no secondary decoration, is a wide range of uses, especially in the construction site for temporary facilities such as office, Wall, etc., but also reflects the modern construction site of civilized construction, especially in the rapid installation and put into use, can be installed in the removable, material turnover index, there are obvious advantages, a substantial reduction in temporary construction site costs, Will be indispensable for new lightweight building materials.

- Q: Not the old bubble sandwich board prices

- Sandwich board 40 yuan per meter type of 5.6 meters 25 sandwich panel 5600 yuan C steel 14 1100 yuan accessories 400 yuan enough sandwich board is 0.25MM / 0.2MM 7.5CM

Send your message to us

aluminum honeycomb panels and sandwich panels

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 888888888 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords