eps roof sandwich panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

EPS Sandwich Panels

EPS Styrofoam Sandwich Panel

Structure | 1.)Steel sheet for both the surface 2.)Explosion polystyrene for the core material |

Steel Sheet Thickness | 0. 3~0.6mm,PPGI |

Panel thickness | 50mm~200mm,common thickness is 50mm,75mm,100mm,150mm and 200mm |

Effective width | 1.) 950/980mm--- Corrugated Roof Panle 2.) 950 / 1150mm---Wall or Ceiling Panel |

Length | Custom, less than 11.8m |

EPS density | 10~20kg/m3 , Normal is 12kg/m3,14kg/m3 |

Color | Regular is White/Red/Blue, also can be Custom |

Heat conductivity | ≤0.045 W/m.k |

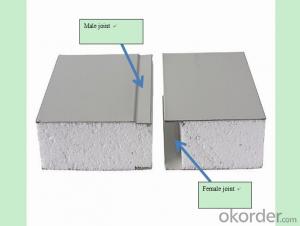

Parts | Steel covered-sides for easy to connect one piece to another, easy to assemble Film covering to protect the steel of panels |

lifetime | 20~25 years |

Character | Light in weight, heat insulation, fireproof and waterproof, fast installation ,environmental |

Use | for all kinds of prefabricated buildings’(warehouse, workshop, garage etc.) roof and wall for existing buildings, can be exterior protected construction or bearing structure |

Packing | Flat packing in shipping Container or according to your demands |

Structure –The EPS panel is constituted by two sheets and middle condensed polystyrene foam board. The upper and lower surface of the panel can be different kind of metal sheets.

Features:

1)Weatherability

EPS covered with fiberglass alkali-resistant mesh and special glue and cement, it has particular weather resistance and durability. It will not crack, bubble and peel when being used in ultraviolet radiation, moisture, salt, heat and cold insulation for long time. Our products are durable and can resist the affects of rain, snow, wind, frost and or other bad weather.

2)Heat insulation and Fireproofing performance

Expandable polystyrene foam incorporated into the panel design shall provide a sufficient thermal break to ensure non-conductivity of temperature between surfaces. The building can reach the standard of energy-saving design without EIFS. It is ideal material for construction in both tropical and frigid countries, it will bring you a comfortable and safe habitation. The core of new self-insulation composite wall material is fireproofing EPS. The completed panels with finished surface are un-inflammable and its fire prevention performance reach B class of GB8624 standards according to testing results from National Center for Quality Supervision and Testing of Fire Building Material.

3)High supporting capability

Individual panel size and configuration is dependent upon project design requirements. The integrated galvanized antirust steel studs for strength is pre-inserted in the wall, and strength of our system depends on the specification and space of steel studs.

4)Installing easily and quickly

It is easy to install with some bonding glue. Our building systems create a single, one-piece corner or T-shaped connecting sections, eliminating the difficult problem of joints between two walls. Wall section is a fully structural, insulated system of factory made sections are easily to assembled on site. Several workers are enough for whole construction, and only need 1/3 time of traditional construction.

5)Excellent strength and durability

Our building systems is customized to the exact architectural drawings, design and specifications and can also be used for almost all kinds of foundation wall system as well as structural floor, wall and roof systems. Formed steel studs shall comprise the integral framework of all panels and sections. It provides lasting strength. Our system and panels shall meet or exceed all code requirements. The houses can be installed without other frame and make the building durable enough.

6)Wide applications

Our building systems could be widely used in exterior wall and partition of villas, residential houses, workshops, cold storages, security lodges, civil engineering, mobile toilets, rubbish centers, transformer substations, sentry boxes and other prefabricated houses.

7)Low Cost--Industry and trade integration

We have our own factory with several production lines manufacturing the panels and sell them through our own trading company. So we can give you the most competitive price and control the delivery time for your benefits!

- Q: Tell us about the polyurethane sandwich panels, and how is its fireproof function?

- Polyurethane sandwich panel is a kind of new type of building material with hard foam polyurethane as sandwich material and color steel cover. It is by the pressure plate, polyurethane insulation materials, under pressure from the composition of the plate together. Polyurethane energy-saving board for the roof tilt of 3% of the class of industrial and commercial buildings, self-cleaning high-grade panel, reducing the amount of roof ash, so that the building roof to maintain long-term crystallization, high crest to improve the carrying capacity of the roof, Large, fast drainage, easy installation and other characteristics, lap at the use of fluid mechanics design to ensure the installation of fast, airtight, anti-capillary water seepage effect. Polyurethane insulation board has a good insulation, heat insulation, noise effects, and polyurethane does not help combustion, in line with fire safety, fire level can reach B level, very suitable for all types of industrial plants, civil construction and public buildings such as steel Bearing roofing.

- Q: What is eps insulation corrugated sandwich panels

- EPS is a foam core material. The so-called insulation sandwich panels is that we often say that the color steel sandwich panels. Color steel sandwich panels are made of color plates and foam composite with insulation properties of the plate, can be used as a roof panel and wall panels. Corrugated refers to the color steel sandwich panel plate type, the conventional color steel sandwich plate type has two kinds of flat and reinforced, corrugated refers to the reinforcement. Above the Shandong Hongxin source for you to provide

- Q: What is the difference between the board and the core board? Usually where the place with sandwich panels where the use of laminates, such as the use of the shoe is the board, wardrobe with a sandwich panel? So what is the difference between the two

- Daxing board is made of two pieces of veneer stagnant stitching wood. Daxin board price is cheaper than the core board, the vertical (to the core material to distinguish) bending strength is poor, but the lateral bending pressure The strength is more ... but the general is best not to choose! 2. Plywood, also known as plywood, some people called the carefully board. Three or more layers by 1mm thick veneer sheet made of hot pressing. Plywood is generally divided into 3mm, 5mm , 9mm, 12mm, ... Plywood Optional plywood is made of multi-layer veneer staggered arrangement of the sheet. The outermost front panel is called the panel, the reverse is called the back plate. Core board.

- Q: Sandwich panel wall design please help?

- If it is to order the plate of this algorithm to die

- Q: Is the factory wall with a sandwich board fire clearance?

- Yanmian, then the fire temperature can reach 700 degrees, two glass wool can only reach 260 degrees, and then there are magnesium, and now the highest fire intensity of the material.

- Q: Color steel polyurethane sandwich panels can do the paint room cut off you

- Of course you can, more expensive, generally recommended with rock wool

- Q: Thickness of rock plate sandwich panels Drawings are written on the F50 color steel rock wool sandwich panels, I would like to ask F50 is the meaning of God, can represent the thickness of it? I asked whether the F50 can represent the thickness of 50 or just a model, in fact, the thickness of 100?

- I have a solution to it. F that Fire, should be the brand is Lokewei it, because Lokowei have 50F and 50C, there are 75F and 75C models, F is the fire board, C said the ordinary version, but 50 can not represent the thickness, because our Offer range, 50F and 50C have 50,80,100,120 mm ... and so the thickness, so 50 can not be the thickness of the thickness of the need for additional set. PS: 50 in Lokovo and intensity (density) have a relationship .50 strength is not high strength of 75. The higher the thickness the thicker the thickness

- Q: Does anyone know the reason why the sandwich panel is bubbling and partially degumming during the pressing process?

- Hydraulic press to suppress the plate, the bubble and local degumming these two phenomena are due to: 1, veneer moisture content is too high or dry uneven 2, the amount of glue is too large 3, buck faster or hot pressing temperature is too high 4, the degree of condensation is not enough resin 5, hot pressing time is insufficient

- Q: Do the closet with a sandwich board? Or with a MDF good?

- Good with sandwich panels

- Q: Rock wool sandwich panels up and down the interface how waterproof

- With a butyl water seal tape placed in the overlapping position.

Send your message to us

eps roof sandwich panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords