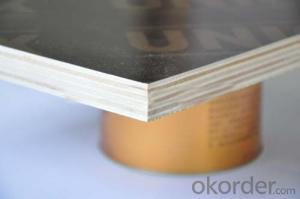

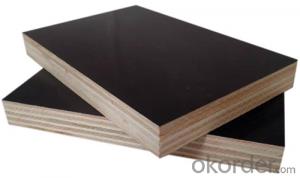

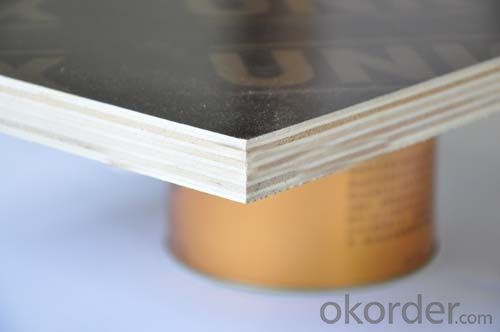

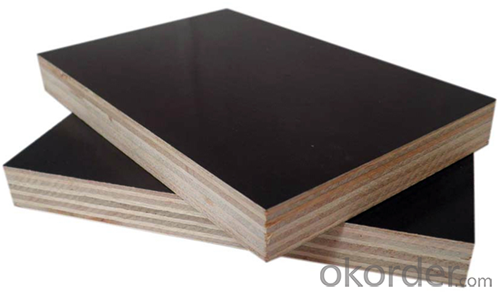

18mm Formwork Black Film Faced Plywood / Marine Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Details

· Type: Plywood

· Place of Origin: Shandong, China (Mainland)

· Brand Name: buildplex

· Usage: Outdoor

· Grade: First-Class

· Main Material: Poplar

· Plywood Type: Other

· Size: 1220x2440mm,1250x2500mm

· Thickness:9mm 12mm, 15mm, 18mm 21mm

· Core: Poplar

· Glue: WBP

· Cycle life: 2-4 times uses

· Film: brown, black, red

· Moisture: below 16%

Packaging & Delivery

Packaging Details: | Standard Export Packing ; Plywood wrapped in 3mm plywood, tied tightly with steel/plastic strips and edges producted with edge protectors. Plywood on pallets. |

Delivery Detail: | within 20 days after receiving LC or deposit |

Product Specification:

Product Name | Film faced plywood |

F/B | Black film, brown film, red film |

Grade | First grade |

Core | poplar |

Glue | WBP |

Thickness | 8-21mm |

Specification | 1220x2440mm, 1250x2500mm |

Moisture Content | 8-13% |

Package | Standard export package on pallet |

Certification | ISO9001 |

MOQ | 1x40HQ |

Price Terms | FOB, CIF,CNF |

Payment | T/T, LC |

Delivery Time | Within 20 days after order confirmed |

Supply Capacity | 5000CBM/month |

Usages | Can be widely used for building concrete, etc |

Remarks | Top class equipment with top class produce technique Credit first, fair trading |

No | Property | Unit | Test Standard | Value of Test | Result | |

1 | Moisture content | % | EN322 | 10 | Check out | |

2 | Density | Kg/m3 | EN322 | 530 | Check out | |

3 | Bonding quality | Bonding quality | Mpa | EN314 | Max:1.27 Min:0.6 | Check out |

Damage rate | % | GB/T17656-1999 | 60% | |||

4 | Bending modules of elasticity | Longitudinal | Mpa |

EN310 | 5800 | Check out |

Lateral | 4500 | |||||

5 | Bending strength(N/mm) | Longitudinal | 40.1 | Check out | ||

Lateral | 33.2 | |||||

6 | Cycle Life | About 2-4 repeated using times according projects by formwork application | ||||

Product Pictures:

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 30 workdays.

Q4: If we can produce some wood products according to customers request?

A4: Yes, we can produce wood products according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Wenzhou Caigang tile and sandwich panels, steel processing costs is how much

- Color steel tile processing 12 yuan package contractor price 70-90 Stainless steel staircase handrail 60-90 steel 80-180 Unit: per square

- Q: Everybody is the polyurethane sandwich board to which manufacturers to buy?

- I came to tell you that I was buying polyurethane sandwich panels to go to Zhejiang Bo Ya building materials, where their products are not only durable, good quality, but also beautiful, there are a variety of styles, all kinds of places can be used on the

- Q: Color steel sandwich panel door how to do?

- Color steel sandwich panel door how to do? This large number of doors in the clean room area, it has ready-made aluminum alloy assembly can be. A small amount can be made with the annex to the material package, with riveting can be.

- Q: Glass wool cotton color steel composite panels, also known as sandwich panels should be how to do re-test? Is it good to do it?

- Do the bare board re-test or do complex panel to see your design requirements and product record is how to prepare. Sometimes it is compound re-examination

- Q: Bubble (EPS) color steel sandwich panels how to wear thread

- That depends on the savvy! Way more than difficult!

- Q: And where are you? Will there be any differences in prices? I am Yuyao, Zhejiang

- 0.5 thick foam board 55 is certainly not buy, even if the real 55 is also cut corners, the basic price of 65 or so, excluding tax, if you want to pack the plate, then more expensive. There is the roof, then the general use of corrugated board, the price is higher. Between 72-75, look at the request. We are here in Suzhou. Can be contacted

- Q: 3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides with the wall of the gap how waterproof ~

- You can try asphalt! Is the kind of paving the way! Very useful!

- Q: in a sandwich panels is there a formula to calculate the amount of foam in the square meter?

- V =1*t where t is the thickness of the foam in meters.

- Q: To do color steel sandwich panels.

- Now is the best in Sichuan

- Q: What is the fire resistance time of the steel wool

- Fire detection report is half an hour

Send your message to us

18mm Formwork Black Film Faced Plywood / Marine Plywood

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords