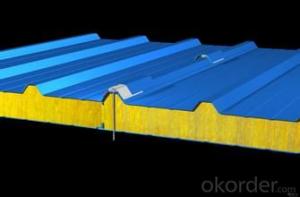

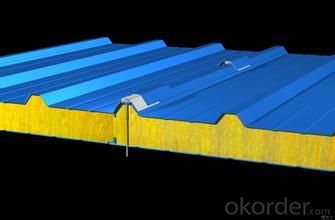

sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| = | |||||

| Panel Material: | Type: | Color: | |||

| Material: | Size: | Name: | |||

| Density: | Features: | Construction Speed: | |||

| Safe: | Anti-earthquak: | Fireproof: |

Packaging & Delivery

| Packaging Detail: | 1. Free Pakage 2. Normal Standard Export Packing |

| Delivery Detail: | Two weeks after payment |

Specifications

1. Environment-protection EPS sandwich panel

2.Sound Insulation

3.Fireproof,

4. Anti-earthquake

5. CE &ISO Passed

- Q: Color steel sandwich panel foam per cubic meter of weight is how much

- Color steel sandwich board phenolic foam bulk density can reach about 50 kilograms per cubic meter

- Q: Color plate and color steel sandwich panel difference?

- Color steel plate galvanized coated iron plate, the use of color steel plate is not insulated. Color steel sandwich panels are double-sided steel plate with the center of the core material through the machine continuous pressure from the type. The core material has foam, rock wool, polyurethane and extruded. The main feature is the insulation of insulation. hope this helps

- Q: What is the rigid polyurethane sandwich panel

- This is a Caigang sandwich panel, can be used as a roof structure of the roof and wall panels, with a large stiffness, than the pressure plate stiffness, thermal performance is also very good, and the polyurethane sandwich panel fire Performance is also good

- Q: Color steel sandwich panel prices

- Look at how much your pricing price ah

- Q: The concept of glass wool cotton sandwich panels

- Composite methods are usually explosive composite, explosive rolling composite, rolling composite and so on. Composite materials can be divided into composite panels, composite pipe, composite bar and so on. Mainly used in anti-corrosion, pressure vessel manufacturing, electric construction, petrochemical, pharmaceutical, light industry, automobile and other industries. Composite material according to the appearance can be divided into composite panels, composite pipe, composite bar and so on.

- Q: 50mm thick insulation color steel sandwich board with J * B42-333 * 1000 What does this mean?

- It may be said that the sandwich board wave height 42 wave width 333 width 1000 bar Oh country mark should not be so that the specification model

- Q: What are the key notes when buying a rock wool sandwich panel?

- There are four key factors: 1. Look at the use of construction: long-term construction or plant application of high quality (rock wool density is equal to 120kg / m3, the outer steel thickness is equal to 0.7mm, thickness of 100mm or more) of the rock wool sandwich panels, because the simple rock Cotton sandwich board after the installation of the surface easy to arch, bubble 2. Flatness: the requirements of the facade of the high demand, the use of mirror flat cotton wool sandwich panels, mirror flat cotton wool sandwich panels than the production of ripples difficult 3. Fire resistance: rock wool board production process should pay attention to the mouth and the mother of the filler, filled with rock wool board fire performance, filled with polyurethane and other materials, poor fire performance 4. Gongkou and the mother after the joint, the horizontal joints at the level of high and low error, high-quality quality rock wool board error is very small, low-end products will be interested in the horizontal slit to 10mm desalination level difference.

- Q: Does the country 's steel market have sandwich panels?

- Sandwich panel products are composed of two layers of metal panels (or other material panels) and directly in the middle of the panel foam, mature molding of the composition of the polymer core insulation. These sandwich panels are easy to install, lightweight and efficient. Filling system is also used to close the molecular structure, you can put an end to the condensation of water vapor. The forming of the outer steel sheet takes into account the structural and strength requirements, and takes into account the appearance, the inner layer is formed into a flat plate to suit various needs. Guoqiang steel market with sandwich panels.

- Q: Is the interior material of the rock wool sandwich panel fluffy or compact?

- This is related to bulk density. Big enough to be dense, you can knock to listen to its voice.

- Q: Lightweight insulation color steel sandwich board clip what the core

- Core material is different, there are foam board, rock wool board and so on

Send your message to us

sandwich panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords