Quick installed polyurethane panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

1.Waterproof and fireproof

2.Easy to install

3.Low thermal conductivity

4.ISO9001:2008, CE

5.Color coated steel surface

Advantages of SWE Polyurethane Sandwich Panels

1.Heat and sound insulation:The outer steel sheets can maintain the lastingness of the color of the building, and reduce the solar radiation and keep the appropriate indoor temperature. The high quality heat insulation materials are made with the adoption of polyurethane PU and (PIR) polyisocyanurate resin acid hydrogen containing no Chloro-fluoro-carbons (CFC).

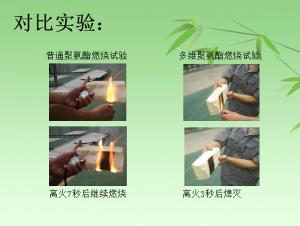

2.A degree inflaming retarding:This system can effectively prevent the fire and prevent the fire from spreading during the cross construction and during the use of the boards

3.Environment protection:By learning after the successful experience in environment protection constructions from companies home and abroad and through our scientific analysis, we objectively bear the idea of “low carbon designing, environmental building materials and energy-saving technology” in mind.

4.Super-low heat conductivity:The lowest heat conducting coefficient of the heat insulation boards ensures that, under the condition that the thinnest heat insulation materials are used; the system can meet the energy-saving requirement and offer the strongest basic guarantee to meet the requirement of high standard heat insulation

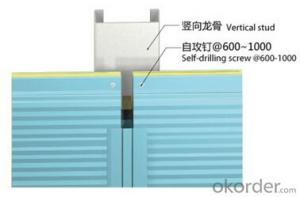

5.SWE polyurethane roof panel are tightly connected blind nailing

6.Easily and quick installation

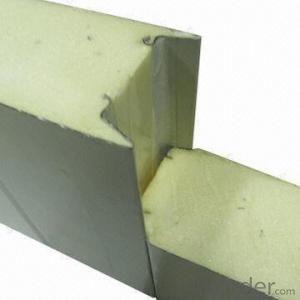

PU sandwich panels is a kind of board used for enclosing structures, which has good heat insulation

and higher intensity.it can reduce the heat transmission caused by difference in the internal and

external temperature, and get to maximum efficiency of freezing and refrigeration systems. Designed

scientifically and easy to use It is a new type of heat insulation material for lower construction cost.

Panels are in multiple varieties and specifications to meet the need of various sites and projects.

After tested by national authoritative testing organization, all technical indicators comply with national

standards.

Specifications

1. PU sandwich panel

2. heat insulation

3. Fire resistant

4. Free sample and drawing deepening

5. Germany product line

Application

PU foam panels are widely applicable to various low-temperature refrigeration storages, air conditioning storages, high-temperature storages and large logistics storages

structure introduction

1.substrate of the board: color steel, stainless steel, or rust-proof aluminum alloy plate(Customers can choose by their own needs). The metal panel and heat insulation core material are foamed, bonded and shaped at one time by Pu pressure injection machine, bringing higher storage board intensity and rigidly.

- Q: Why do you want to use polyurethane seal on both sides of the multi-dimensional joint group of OKorder Yanmian sandwich panels

- As a new type of rock wool sandwich panels, his plate is a dark buckle is not nails, so that the board on both sides of the plug interface into the opposite sex, and in the production process sent by the rock wool is equal thickness, which makes The mouth and the mouth of the mouth of the cotton-free cavity, and the subsequent manual joints, but also produce cotton and steel plate bonding performance is poor, anti-stripping poor, this result will be cold in the winter, summer will produce heat Bridge, the more serious is in the wall board, bear the load object entirely by the self-tapping to bear, and because the rock wool sandwich panel is horizontal installation, and its two sides of the plug interface becomes the upper and lower parts, and its Is empty, so that the rock wool is completely attached to the steel by glue, a long time, rock wool fall, resulting in deformation

- Q: Hanging plate, color plate, sandwich panels, pressure plate the same?

- Sandwich panels and Caigang sandwich panels is one thing, are double-color steel plate folder folder insulation material, food production workshop with sandwich panels can

- Q: Corrugated polyurethane sandwich board how much money a square meter?

- According to the requirements of different standards ranging from 120-300, where the factors that affect the price too much, one or two that is not clear

- Q: Does the color steel sandwich panel plant require an environmental permit?

- (1) a copy of the application form for environmental management of the construction project; (2) the registration form of the proposed environmental impact of the project; (3) the project proposal and the relevant department approval document of the project proposal; (4) Topographic map, the map should be marked around the proposed project; (5) the proposed project to be approved by the local Environmental Protection Agency.

- Q: EPS sandwich panels, PU sandwich panels and rock wool sandwich panels of the sound effects which is good?

- Fireproof rock wool> Glass wool> PU> EPS Insulation EPS> PU> Yanmian> Glass wool Sound insulation with almost the same Price PU> glass wool cotton = rock wool> eps So much about it

- Q: Explosion-proof rock wool sandwich panel how to do waterproof

- Do a good job of waterproof coating treatment, the other is, you can in its surface, composite layer of metal, so you can better waterproof moisture Oh.

- Q: Sandwich panel wall design please help?

- Is this 127 square? 5.45 and 3.85 are two sides of the width of the original is a large, now divided into two large one small, long is 15 meters, in front of the board height is 3.27 meters. Followed by 2.87 on both sides of the wide plate height is 3.2 meters. So calculated out of 127 square feet

- Q: Which color plate sandwich board price is low and good insulation

- Polyurethane sandwich panel comprehensive performance is better. fair price. Tianfeng good

- Q: 50mm thick roof color steel sandwich board price is generally how much money a m2?

- Depends on the thickness of the color plate, different thickness of the color plate is not the same. For example: color plate thickness: 0.28mm thick: 0.2mm need 40 yuan / m.

- Q: Steel structure, activities, such as sandwich panels board generally what kind of self-tapping screws fixed ah?

- Self-tapping screw, the English name Self-tapping Screw is a metal or non-metallic materials in the pre-drilling hole in the self-drilling with a female thread with a threaded fastener. Self-tapping screws are used for connection between thin metal plates (steel plates, saw boards, etc.). When connecting, first thread the bottom of the connector, and then screw the tapping screw into the threaded bottom hole of the connected part. As the tapping screw thread surface has a high hardness (≥ 45HRC), can be connected to the threaded bottom hole in the internal thread, thus forming a connection.

Send your message to us

Quick installed polyurethane panels

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords