CMAX 960B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Series Hydraulic Static Pile Driver for Sale

ZYJ series hydraulic static pile driver is the product for building pile foundation construction under the independent research and development of our company and with more than 10 national patented technologies. It is a novel environmentally friendly construction equipment characterized by no pollution, no noise, no vibration, fast pressing of pile as well as high pile quality, and represents the development direction of piling machinery. Since mass production, its domestic market share has been firmly first, and our company has become a professional enterprise with research and development, production and sales of domestic pile machine taking the lead. The product won the second prize of the State Scientific and Technological Progress Award in 2003, becoming the famous-brand product of Hunan. Our company participated in drafting the Hydraulic Pile Driver industrial standard (JB/T11674 2013), which greatly promotes the development and progress of technology of static pile driver and pipe pile industry in China. Our company completed the upgrading of product design in 2013 to comprehensively improve the configuration, performance and quality, and the products are well welcomed and praised by the customers since it was put on the market.

Feature:

1. High-efficiency and energy-saving piling system with quasi constant power

2. Humanized driver cab and concise and clear control console

3. Piling oil cylinder and motor pump set with scientific and reasonable matching

4. Patented technology - fast return of piling oil cylinder

5. Clear and simple hydraulic piping layout

6. Patented technology - multipoint pressure-equalizing gripper mechanism

7. Unique "side piling and angle piling" device

8. Steel H-shaped pile can be pressed into the trapezoidal and triangular piles according to customer requirements.

9. Simple structure and easy transport

10. New hydraulic walking chassis

11. New patent – side piling device

| Parameter | ZYJ960B-II | |

|---|---|---|

| Dimension | Length mm | 16115 |

| Width mm | 9100 | |

| Height mm | 3220 | |

| tf Max.piling force | 960 | |

| m/min Max.piling speed | 7.3 | |

| Travel Capacity | Lengthwise m | 3.6 |

| Widthwise m | 0.7 | |

| Angel ° | 12 | |

| Standard crane model | 25 | |

| Grounding Pressure | (Kpa)Long ship | 151 |

| (Kpa)Short ship | 204 | |

| Side pile distance mm | 995 | |

| Comer pile distance mm | 2500 | |

| Max round pile mm | 800 | |

| Max square pile mm | 800 | |

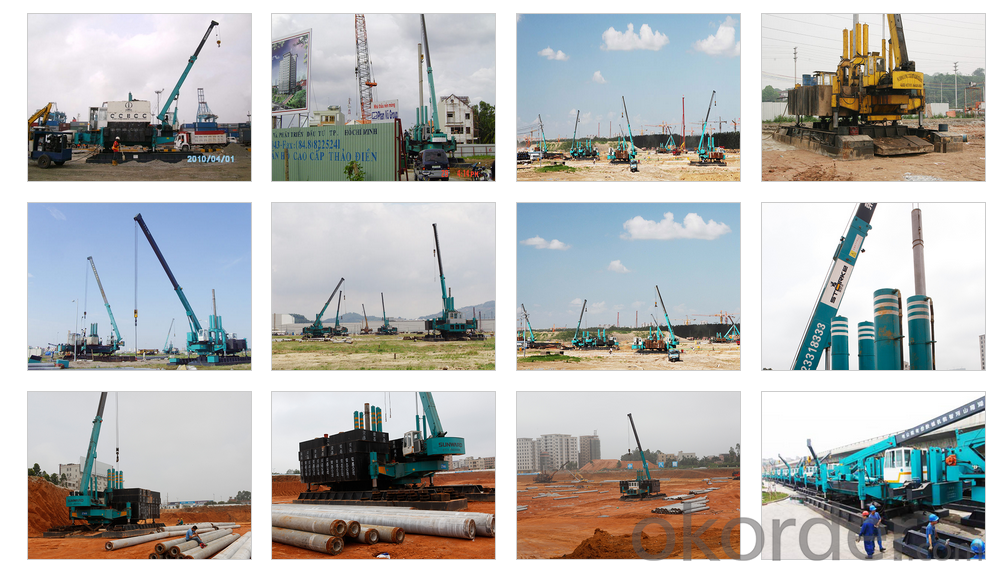

Cases

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: Pile up can not go down, how to deal with?

- 1. If the hammer is reached, the hammer is finished.2, according to the geological report should be able to play but did not move, can not continue to fight, otherwise the pile will crack or break, stop and find out the reason.

- Q: How did the pile of clay work after the pile driver finished?

- After the pile driver has finished the pile, the concrete is usually pumped under the concrete.Classification by load characteristicsFriction pileFriction piles - most of the load is caused by the friction of the soil around the pile, and the resistance at the end of the pile is negligible.End bearing friction pile -- the pile whose load is mainly borne by the friction force of the pile body.End bearing pileEnd bearing piles - most of the load is carried by the supporting force of the pile tip, while the resistance at the side of the pile is negligible.

- Q: Is the architecture of the pile driver strong in single core performance or multi - core capability? Or?

- Overall, the AMD's nuclear performance has not been improved for almost 10 years. Basically maintained at the level of K8.

- Q: Pile driver, pile, cylinder, oil seal installed, there is no positive and negative

- Yes, no, you can take pictures before changing the seal, then change the seal.

- Q: What is the starting current for a 55 kW pile driver? What's the big leakage switch, please?

- 55KW motor, rated current of about 110A.If it is started directly, the starting current is about 450A---800A.You can choose 150A with leakage protection circuit breaker.

- Q: How much power does piling work at a construction site?

- You see what device ah, various devices are not the same, but to remind you that the cable in piling time as far as possible with a point, otherwise it is easy to jump, because during each equipment operation at the same time, need a larger coefficient.

- Q: What safety measures should be taken when assembling a pile driver?

- This thing must have the safety, rules and regulations, but the key is to have this awareness, the following for your reference, I hope to help you.1 、 safety management system of mechanical equipmentLeaders at all levels should strengthen the safety work of mechanical equipment often carry out safety production leadership, ideological education and safety education of workers, the leaders at all levels included in the safety target management schedule, prohibited illegal command, illegal operation, violation of labor discipline and reckless ignorance and other unsafe behavior, leaders should regularly organize relevant personnel go to the scene, the supervision and inspection of mechanical safety work, to correct the problem, promptly eliminate hidden dangers, make the mechanical equipment to achieve safety, high quality, high efficiency and low energy consumption operation, the long-term safe production and take measures to eliminate hidden dangers and prevent accidents of personnel should be commended and rewarded.Urge all kinds of machinery and equipment operators to seriously study safety technical operation procedures, and those who violate safety technical procedures must be stopped, and can be continued before improvement. After the arrival of the new model, there is no safety technical operating procedures, it must be in accordance with the requirements of the instructions, first formulate safety operation procedures and precautions before they can be put into use.

- Q: How many types of piles are there in the site? What procedures are usually used for piling? Such as eyes open what kind of..

- Precast pile, artificial dig hole pile, sinking pipe filling pile, spiral drilling pouring pile and powder spraying pile.

- Q: Can a pile driver hit a rock?

- A lock of rotary drilling rig advantage Hui omron:1, the fastest 20 minutes, you can dig 15 meters of earth drilling2, drilling can be broken cement concrete floor.3, the use of XCMG power head, multi-stage shock absorption technology to ensure that the overall construction of more stable, power head key bar used in reverse and used to extend its service life.4 、 adopting the lock rod of the XCMG machine and the automatic lowering technique of the mast. The vertical precision of the pile hole is higher, and the construction is more convenient.5, the well-known brand "Yuchai engine," every little hour consumption 40-50 yuan.6, the use of wide, tube rice suitable for medium weathering below rock layer, sediment layer, backfill soil layer and other complex landforms.

- Q: What pile driving machine should be used for the 400*400 square pile?

- The cylinder type diesel hammer takes the cylinder as the hammer seat and directly uses the lengthened cylinder to guide the inner wall. The two guiding rods are omitted, and the plunger is a hammer head, which can move up and down in the cylinder. When piling, the pile cap at the bottom of the hammer block is pressed on the top of the pile, lifting the plunger with a hook, and then decoupling and downward impacting to compress the air enclosed in the cylinder. And fuel injection, explosion, shock, ventilation and other work processes. Diesel hammer work is on compression ignition diesel to start, it is necessary to ensure the closed gas cylinder reaches a certain compression ratio, sometimes piling in soft soil layer is often because the reaction is too small, the amount of compression is not sufficient to ignite the ignition, it needs to use the hook to lift a hammer from multiple impact, to start. The hammer seat of the diesel hammer is provided with a fuel injection pump, an oil tank, a cooling water tank and a pile cap. The movable gap between the plunger and the cylinder is sealed with an elastic plunger ring.

Send your message to us

CMAX 960B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords