CMAX 460B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CMAX Series Hydraulic Static Pile Driver for Sale

ZYJ series hydraulic static pile driver is the product for building pile foundation construction under the independent research and development of our company and with more than 10 national patented technologies. It is a novel environmentally friendly construction equipment characterized by no pollution, no noise, no vibration, fast pressing of pile as well as high pile quality, and represents the development direction of piling machinery. Since mass production, its domestic market share has been firmly first, and our company has become a professional enterprise with research and development, production and sales of domestic pile machine taking the lead. The product won the second prize of the State Scientific and Technological Progress Award in 2003, becoming the famous-brand product of Hunan. Our company participated in drafting the Hydraulic Pile Driver industrial standard (JB/T11674 2013), which greatly promotes the development and progress of technology of static pile driver and pipe pile industry in China. Our company completed the upgrading of product design in 2013 to comprehensively improve the configuration, performance and quality, and the products are well welcomed and praised by the customers since it was put on the market.

Feature:

1. High-efficiency and energy-saving piling system with quasi constant power

2. Humanized driver cab and concise and clear control console

3. Piling oil cylinder and motor pump set with scientific and reasonable matching

4. Patented technology - fast return of piling oil cylinder

5. Clear and simple hydraulic piping layout

6. Patented technology - multipoint pressure-equalizing gripper mechanism

7. Unique "side piling and angle piling" device

8. Steel H-shaped pile can be pressed into the trapezoidal and triangular piles according to customer requirements.

9. Simple structure and easy transport

10. New hydraulic walking chassis

11. New patent – side piling device

| Parameter | ZYJ460B-II | |

|---|---|---|

| Dimension | Length mm | 12800 |

| Width mm | 7345 | |

| Height mm | 3100 | |

| tf Max.piling force | 460 | |

| m/min Max.piling speed | 7.1 | |

| Travel Capacity | Lengthwise m | 3.6 |

| Widthwise m | 0.6 | |

| Angel ° | 10° | |

| Standard crane model | QY12C/QY16D | |

| Grounding Pressure | (Kpa)Long ship | 112 |

| (Kpa)Short ship | 155 | |

| Side pile distance mm | 1045 | |

| Comer pile distance mm | 2230 | |

| Max round pile mm | 600 | |

| Max square pile mm | 600 | |

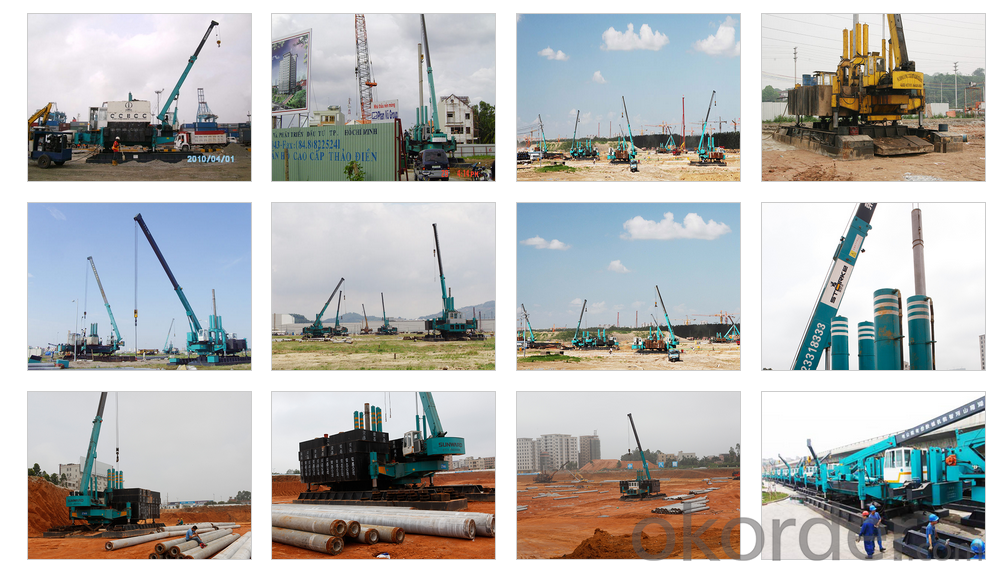

Cases

FAQ

1.Which payment terms can we accept?

Normally we can work on T/T term or L/C.If you choose T/T,30% payment is required in advance and 70% balance shall be settled before shipment often,it rang a little.

2.How long will our price be valid?

We are friendly dealer, never greedy windfall profit, our price remains stable,except the exchange rate and the increasing labor cost and material cost.

3.What are our advantages compared with manufacturers?

a.Detailed training-We can provide training services to different users. The training sessions include product training,operating training, maintenance know-how,standard and so on to fulfill your individual needs.The training can be conducted at client’s site.

b.Available after service-With our global distributor network, you are guaranteed with fast deliveries and services if you submit your requests.

- Q: How many meters can a small pile driver reach?

- Hello! A square bar in Hunan wylong machinery is probably less than 20 no problem.

- Q: The grounding of piling machine. Pile machine, three-phase asynchronous motor one day to play 2 piles piling machine and control box are constantly moving, how to ground? And is not a machine box. A gate or a few feet to ground is the five core. In three, the rest of the root, the zero line and the PE are useless? Thank you, predecessors, great God under the guidance of? In this way, the master said that the reception will be over, installed a leak protection, is not installed, the leak insurance does not need to ground ah?

- The pile driver must be grounded reliably! Five core power cable, PE core wire may reach 16 square, in pile machine within 30 meters hit a 3 meter long galvanized angle (angle 50X5X3000), the head of a hole on the M10 (or M12) galvanized bolts, connecting 16 square BVR yellow green color line to the pile machine (repeat grounding), angle head (to prevent the hammer head welding deformation angle) a piece of iron, if you want to reuse (pull out in place again), can be connected with the hanging wire rope or a hook hole in angle steel.

- Q: The ground site must be driven by a pile driver

- If the foundation is made of prefabricated piles, it must be driven by a pile driver. If it is a pile, it will not need a pile driver.If it is an ordinary low rise house or a general pavement foundation, it only needs to be treated by damp proof and hardening, without piling.

- Q: What are the characteristics of hydraulic static piling compared with traditional pile driver?

- The pile is pressed by its own weight. Besides the weight of the pile, the weight of the pile should be installed with a total weight of more than 600 tons to the thousand tons.There is a large power hydraulic pump station with maximum power of more than 300 kW at run time.The pressure prefabricated pipe pile is clamped by hydraulic cylinder and pressed down by segment. The noise and vibration are smaller, and the bearing capacity can be known.Pile with hook.

- Q: How many prestressed concrete pipe piles can a pile driver hit in a day?

- 1, a pile driver can play the prestressed concrete pipe pile in a day, and the number of skilled workers, geological conditions, as well as the quality of the pile driver. Under normal circumstances, you can hit around 400 a day.2, in order to make up for the prestressed concrete concrete cracks in the phenomenon, in the use of components (load) before, to advance a concrete pre pressure in concrete in the tensile zone, using the method of artificial force, reinforced by stretching, the retraction force of steel, the tension zone of the concrete in advance under pressure. This stored pre pressure, when the components bear the tension produced by the load when the first offset by pre stress tension zone in concrete, and with the increase of load, the concrete tension, which limits the concrete elongation, delay or not lead to cracks, which is called prestressed concrete. Prestressed concrete pipe pile is a kind of precast concrete pile, which embodies the progress of modern concrete technology and the high and new technology level of concrete products.3, [prestressing: force] is a prestressed prestressed structure in order to improve the service performance during the construction to the structure of pre applied stress structures of pre compressive stress can be wholly or partially offset load caused by tensile stress, avoid structural damage. Commonly used in concrete structure, concrete structure under load is before, in advance to put pressure on it to make it in the outside load when the concrete tensile stress compressive stress produced in order to offset or reduce the load due to the tensile stress, the structure in the case of normal cracks or crack late.

- Q: Pile driver, pile, cylinder, oil seal installed, there is no positive and negative

- Yes, no, you can take pictures before changing the seal, then change the seal. Sealed single role and double action, such as lip mouth should be facing the hydraulic side. You can't ask me

- Q: Code for installation and operation of pile drivers

- 4. Check whether the voltage of the power supply meets the requirements.5, according to the daily maintenance project to each department lubrication, maintenance.Five, pile driver in the work safety precautions:1, when the piling machine work, there should be special command. The conductor and operator should check each other's signals before they work. Work closely together.2, at the start of the bell signal or other applications, notify the staff around to leave.3, hammer and pile cap, pile cap and column (or pile) plane to pad, a connecting bolt should be tightened, and should always check whether there is loose.4. The starting of the pile driver should be adjusted from low gear to high speed.5, the pile driver in the work should be closely observed on the control panel current, voltage instructions. If abnormal sound or other abnormal conditions are found, stop inspection immediately.6, always check the temperature of the bearing and the bearing cover screws is loosening, should strictly examine the eccentric block coupling screw loosening, prevent the occurrence of accidents.7, sink, column (or pile) prohibited to stand around.8, piling machine with water, mud suction sink, should contact in advance with the relevant personnel, and take care of each other at work.9, long pipe column or pile and the installation of pile cap, the staff must wear safety belts.10 、 in the process of sinking, it is strictly prohibited to do mechanical maintenance work.Six after the stop of the piling machine, the power shall be cut off immediately, and the pile driver and motor shall be inspected and maintained.Seven, piling machine long-term disabled, should be kept in storage, the motor should be good moisture-proof protection, the control panel of the instrument, should be removed, storage, storage.

- Q: What are the types of hammer pile drivers?

- There are diesel tube pile driver, power source brand, Zhong Zhong brand, and Zhejiang is very popular guide rod hammer

- Q: Safety requirements for diesel hammer pile drivers for diesel hammer pile drivers

- 19, the operation should always check whether the fasteners are loose, the moving parts are flexible. Diesel pile hammer after the operation note 20 after the operation, diesel hammer should be parked in a solid flat ground, diesel hammer should be placed on the ground plate or into underground pile, shutting down the fuel switch, barrel type hammer should be put in the net cooling water, mounted on the cylinder head, exhaust cover, safety screw etc., and mounted on the safety card. The pile holder shall be placed in a stop position, locking the safe and braking position. 21 rail type pile holder should clamp the rail clamp when it is not working. When the 22 pile stand is broken, the brake performance of the hoister shall be checked first, and then operated according to the procedures specified in the instruction manual. 23, long-term disabled, should be unloaded diesel hammer, loaded with safety board, the diesel hammer fuel, lubricating oil and cooling water all out, cleaning the combustion chamber, coated with anti rust oil on the ball bowl, and take rainproof measures.

- Q: How can I find a pile driver?

- Go to the construction site, it is better to have known the construction team, or the construction company pull!

Send your message to us

CMAX 460B-II Series Hydraulic Static Pile Driver for Sale

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords