circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

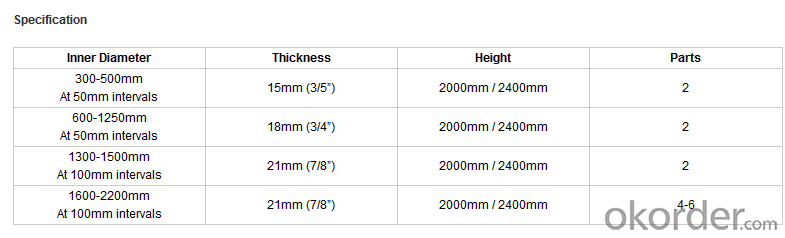

Specification

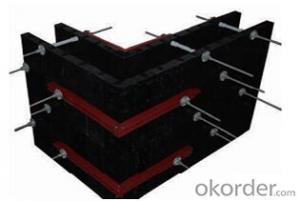

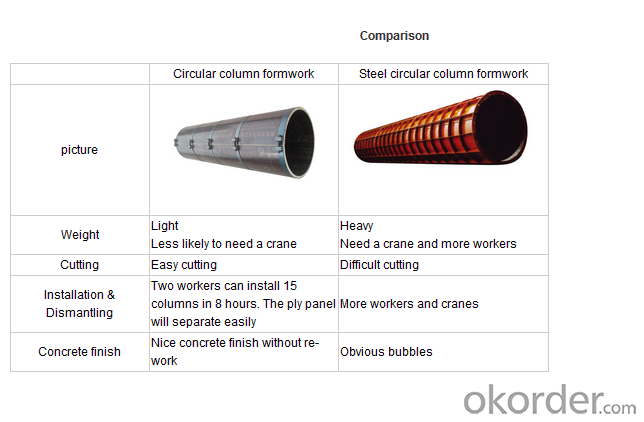

wholeasale circular column formwork customized size quick form easy cuting

1. Made of plywood, light weight, easy handling

2. Grooves prevent the leakage of concrete

3. Easy cutting

4. Efficient installation and dismantling

5.Nice concrete finish without re-work

Application

For concrete forming of circular columns

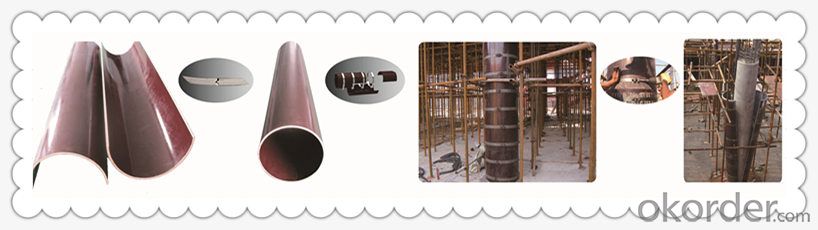

Installation

1.Treat inner ply film with concrete release agent firstly.

2.Fix the steel belts horizontally according to the lines.

3.If the height is more than 3000mm , please install it as the indication below.

4.Fromfeedback on site, only 2 skilled workers can install 15 circular columns in 8 hours.

Dismantling

Simply untie the steel belts and the ply will separate easily.

Maintenance & Storage

Lightly treat the ply film with oil before next usage.

place the formwork vertical, away from direct sunlight and water.

Package and shipment

On Site

- Q: How does steel frame formwork affect the overall dimensional accuracy of a concrete structure?

- Steel frame formwork can significantly improve the overall dimensional accuracy of a concrete structure. The rigid and stable nature of steel frame formwork ensures that the concrete is poured and set in the desired shape and size, minimizing the chances of any shrinkage or deformations. This formwork system provides precise support and alignment during the construction process, resulting in a more accurate and consistent finished product.

- Q: Can steel frame formwork be used in projects with high concrete pour heights?

- Indeed, projects with high concrete pour heights can effectively utilize steel frame formwork. Renowned for its robustness, longevity, and capacity to endure immense pressure during concrete pouring, steel frame formwork offers a steadfast and reliable structure for pouring concrete at diverse elevations. Furthermore, the assembly and disassembly of steel frame formwork is effortless, facilitating efficient utilization and reuse in projects with fluctuating pour heights. Its versatility and adaptability render it an ideal option for construction endeavors necessitating substantial concrete pour heights.

- Q: Are there any environmental considerations when using steel frame formwork?

- Yes, there are several environmental considerations when using steel frame formwork. Steel production has a significant carbon footprint and contributes to greenhouse gas emissions. Additionally, the extraction of raw materials for steel production can lead to habitat destruction and ecosystem disruption. However, steel formwork can be reused multiple times, reducing the need for new materials and minimizing waste generation. Proper disposal and recycling of steel formwork after its useful life should also be considered to minimize environmental impact.

- Q: Do steel frame formwork systems require any additional support or reinforcement?

- Yes, steel frame formwork systems often require additional support or reinforcement depending on the specific construction project. While steel frame formwork systems are generally strong and sturdy, they may need additional support to handle larger concrete loads or to ensure stability during the construction process. Additional support or reinforcement can be provided through various means. For example, diagonal bracing can be used to strengthen the steel frame and prevent any potential deformation or collapse. Similarly, steel props or shoring systems may be required to provide additional support to the formwork, especially in cases where the concrete loads are high or the formwork spans large distances. In some instances, engineers may also recommend using tie rods, walers, or other structural elements to reinforce the steel frame formwork system. These elements can help distribute the loads evenly and provide the necessary stability to the formwork during concrete pouring and curing. Ultimately, the need for additional support or reinforcement will depend on the specific project requirements, including the size and complexity of the structure, the concrete loads involved, and the safety standards to be adhered to. It is crucial to consult with a qualified structural engineer or construction professional to determine the appropriate level of support or reinforcement needed for a steel frame formwork system.

- Q: How does steel frame formwork handle the construction of suspended slabs and beams?

- Steel frame formwork is a versatile and efficient method for handling the construction of suspended slabs and beams. This construction technique involves the use of a steel frame that is specifically designed to support and hold the concrete in place during the pouring and curing process. One of the key advantages of steel frame formwork is its strength and durability, which makes it ideal for supporting the weight of suspended slabs and beams. The steel frame is able to withstand the pressure and weight of the concrete, ensuring that the structure remains stable and secure throughout the construction process. Furthermore, steel frame formwork offers flexibility in terms of design and customization. It can be easily adjusted and modified to meet the specific requirements of different slab and beam configurations. This means that contractors have the ability to create unique and complex designs without compromising on structural integrity. In addition, steel frame formwork provides a smooth and even surface finish, resulting in high-quality and aesthetically pleasing slabs and beams. The formwork system is designed to prevent any leakage or seepage of the concrete, ensuring that the end result is a durable and visually appealing structure. Moreover, steel frame formwork offers faster construction times compared to traditional methods. The pre-fabricated steel frames can be easily assembled and disassembled, allowing for efficient installation and removal. This reduces the overall construction time and increases productivity on the construction site. Overall, the use of steel frame formwork for suspended slabs and beams provides numerous benefits, including strength, durability, flexibility, and efficiency. It is a reliable and cost-effective construction technique that is widely used in the industry.

- Q: How does steel frame formwork handle different types of formwork curing techniques?

- Steel frame formwork is a versatile and durable system that can effectively handle different types of formwork curing techniques. The steel frame provides excellent support and stability, allowing for various curing methods to be implemented. One common technique is the traditional wet curing method, where the formwork is kept damp with water to facilitate proper hydration of the concrete. Steel frame formwork is designed to withstand the moisture and pressure associated with wet curing. The steel frames are typically coated with anti-corrosion materials, ensuring their longevity and resilience against water exposure. Another technique is the use of curing compounds or membranes, which are applied to the formwork surface to create a barrier that retains moisture and promotes proper curing. The smooth surface of the steel frame formwork allows for easy application and adherence of these compounds. The steel frames also provide a solid base for the curing compounds to bond with, ensuring a strong and effective curing process. Additionally, steel frame formwork can accommodate the use of insulating materials for curing, such as thermal blankets or foam boards. These materials are placed on the formwork surface to retain heat and promote a controlled curing environment, especially in colder climates. The steel frame formwork provides a sturdy structure to support the weight of the insulating materials and ensures proper insulation throughout the curing process. Overall, steel frame formwork is well-suited to handle different types of formwork curing techniques. Its strength, durability, and resistance to moisture make it a reliable choice for various curing methods. Whether it is wet curing, curing compounds, or insulation, the steel frame formwork system can effectively support and facilitate the curing process, resulting in high-quality and durable concrete structures.

- Q: What is the maximum permissible deflection of steel frame formwork panels?

- The maximum permissible deflection of steel frame formwork panels depends on several factors, including the type of steel used, the panel dimensions, and the specific application. Generally, the deflection limit for steel frame formwork panels is determined based on industry standards and guidelines. In accordance with these standards, the maximum permissible deflection for steel frame formwork panels is typically limited to L/400 or L/600, where L represents the span of the panel. This means that the deflection should not exceed 1/400th or 1/600th of the span length. For example, if the span length of a steel frame formwork panel is 3 meters, the maximum permissible deflection would be 7.5 mm (L/400) or 5 mm (L/600). This deflection limit ensures that the formwork panels maintain their structural integrity and do not adversely affect the quality and accuracy of the concrete structure being formed. It is important to note that these deflection limits are general guidelines, and specific projects may have their own requirements or specifications. Therefore, it is advisable to consult the relevant codes, standards, and design professionals to determine the maximum permissible deflection for steel frame formwork panels in a particular project.

- Q: Are there any specific training requirements for using steel frame formwork?

- Yes, there are specific training requirements for using steel frame formwork. Steel frame formwork is a specialized construction technique that requires knowledge and skills to ensure its safe and effective use. Training in using steel frame formwork typically covers various aspects such as understanding the design, assembly, and dismantling procedures of the formwork system. This includes learning how to properly align and secure the steel frames, install the necessary support and bracing systems, and ensure the stability and integrity of the formwork structure. Additionally, training may also include instruction on the proper handling and storage of steel frame formwork components, as well as techniques for minimizing the risk of accidents and injuries during construction activities. It is important for individuals working with steel frame formwork to be trained in recognizing and addressing potential hazards, such as unstable ground conditions, overhead obstructions, or adverse weather conditions. They should also be educated on the use of personal protective equipment and the implementation of safety measures to prevent falls, trips, and other accidents on the construction site. Overall, proper training in using steel frame formwork is essential to ensure the safety of workers and the quality of the construction project. Employers should provide comprehensive training programs and ensure that all personnel involved in the use of steel frame formwork have received the necessary training and possess the required competencies to carry out their tasks effectively and safely.

- Q: Does steel frame formwork require any special bracing or support during construction?

- Special bracing or support is necessary for steel frame formwork during construction. Steel frame formwork serves as a temporary structure that holds and supports wet concrete until it solidifies and becomes self-supporting. The system consists of vertical and horizontal metal beams connected with various connectors and braces. To maintain stability and safety, the steel frame formwork must be appropriately braced and supported during construction. Bracing is crucial to prevent the formwork from collapsing or deforming under the weight of the wet concrete. It evenly distributes the load and provides additional support to the formwork system. The specific bracing requirements for steel frame formwork depend on factors such as formwork height and size, concrete pressure, and the structure's design. Bracing options include diagonal or cross braces, tie rods, horizontal and vertical struts, and adjustable clamps or props. The bracing system must be designed and installed by experienced professionals who can ensure it can withstand the forces and pressures exerted by the wet concrete. It is important to follow the manufacturer's instructions and guidelines for bracing and support to maintain the structural integrity of the steel frame formwork system. In conclusion, special bracing or support is necessary for steel frame formwork during construction to ensure stability and safety. Proper bracing is vital in preventing the collapse or deformation of the formwork system due to the weight of the wet concrete. The type and amount of bracing required depend on various factors and should be designed and installed by professionals in accordance with the manufacturer's guidelines.

- Q: What are the different types of support brackets used with steel frame formwork?

- There are several types of support brackets that are commonly used with steel frame formwork. These brackets are designed to provide stability and support to the formwork system, ensuring that it can hold the weight of the concrete during the pouring and curing process. Some of the different types of support brackets include: 1. Adjustable brackets: These brackets are designed to be adjustable in height, allowing for flexibility in the formwork system. They can be easily adjusted to the desired height and locked in place, providing support at various levels. 2. Fixed brackets: These brackets are fixed in height and cannot be adjusted. They are typically used in situations where a constant height is required, such as when forming a slab with a consistent thickness. 3. Corner brackets: These brackets are specifically designed for use at the corners of the formwork system. They provide additional support and stability to ensure that the corners of the concrete structure are properly formed. 4. Wall brackets: These brackets are used to support the formwork system when forming vertical walls. They are typically attached to the existing structure or to vertical beams, providing support for the formwork panels. 5. Beam brackets: These brackets are used to support the formwork system when forming horizontal beams. They are typically attached to vertical beams or columns, providing support for the formwork panels that are used to create the beam. 6. Slab brackets: These brackets are used to support the formwork system when forming a horizontal slab. They are typically attached to vertical beams or columns, providing support for the formwork panels that are used to create the slab. Overall, the different types of support brackets used with steel frame formwork are designed to provide stability and support to the formwork system, ensuring that it can hold the weight of the concrete during the construction process. These brackets are essential in creating strong and reliable concrete structures.

Send your message to us

circular column formwork wooden lightweight for concrete column round pillar

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 60000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords