China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profile Glass Wall Usage and Best Quality Description:

We have more than 10 years experiences on manufacturing kinds of aluminum profiles, such as Aluminum Window & Door profiles, Aluminum tile trim profiles, Aluminum profiles for LED light, Round/Square General profiles, Aluminum heat sink, Aluminum heating insulation profiles, Curtain wall Aluminum profiles, and others Industry profiles.

Our products have exported to all over the world, and we also have a large of market share in Algeria, Angola, Philippine, Guinea, Ghana, South Africa, Nepal, Nigeria, Tanzania, Iraq etc.

Main Features of the Aluminium Profile Glass Wall Usage and Best Quality:

1, Strong R&G: help customers finalize the design, strong tool design ability, excellent, pressing and surface treatment technology;

2, Strong quality management: ISO&SGS SYSTEM;

3, 24 hours on-line communication, professional, patient, flexible;

4, High capacity of manufacturing and wide range of products;

5, We can provide secondary manufacturing.

6, High corrosion resistance, high weather resistance and good wear resistance.

7, Alternative surface treatment: Colorful ANODIZE, POWDER COATING, ELECTROPHORESIS & WOODEN GRAIN. Plentiful colors upon your needs.

8, Excellent material for smooth and subtle edges, elegant appearance.

9, Strong coated adhesion which is suitable for construction and industrial material.

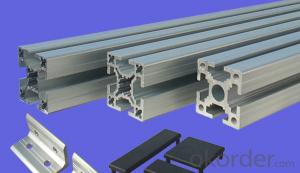

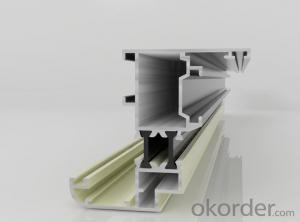

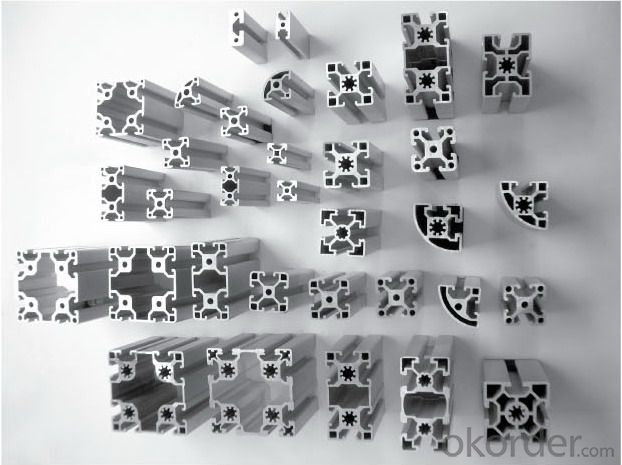

Images of the Aluminium Profile Glass Wall Usage and Best Quality:

Aluminium Profile Glass Wall Usage and Best Quality Specification:

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

FAQ:

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: What is the hardness range of aluminum coils?

- The hardness range of aluminum coils typically falls between 40 and 70 on the Rockwell hardness scale.

- Q: If so why does an aluminum bend or get nicked or break quickly?

- MPCheu is on the right track. Bending and getting nicked so it will break quickly are different things than strength and there are many different types of strength. Previous answers are correct regarding specific strength, say yield strength per unit mass because Al is much less dense than iron (the primary component of steel). It is also worth noting that there are many different types of steels and any one of these steels can have a very large range of mechanical properties. Same is true of aluminum alloys. The reason most airplanes are made using Al alloys is all about this specific strength and it is the same reason Al alloys are being replace by composite materials which have even higher specific strengths, densities about the same as Al but with much higher strengths. hope this helps

- Q: I read the back of my deodorant and it said that it contains 14% Aluminum. Is that harmful for my baby?

- It's probably an anti-perspirant, right? That blocks sweat glands and is not healthy for you; not sure about the baby. You should only use deodorant - not anti-perspirant.

- Q: What is the maximum coil weight that can be produced?

- The maximum coil weight that can be produced depends on several factors such as the type of material being coiled, the size and capacity of the coiling equipment, and the strength and durability of the coil itself. In general, the maximum coil weight that can be produced can range from a few pounds to several tons. However, it is important to note that exceeding the recommended maximum coil weight can pose safety risks, cause damage to the equipment, and affect the quality and integrity of the coil. Therefore, it is essential to consult the manufacturer's guidelines and specifications to determine the maximum coil weight that can be safely and efficiently produced for a specific application.

- Q: I know that Aluminum is a metal, and it's corrosive, but I've been wondering about how Aluminum Foil is created. Is it the same as the metal? Just pounded down? or is it a mixture of different elements?

- It is made by rolling an aluminum block thinner and thinner. Metal foil, such as tin foil had been around for years. The first plant designed for rolling aluminum foil was opened in 1910. NASA was not in existence then. It appears the inventor was: Hans Christian Oersted Year Invented: 1825 P.S. Aluminum is not corrosive. corrosive means it corrodes other things (as acid would). It does corrode. It is also the most reactive metal. It is oxidized immediately upon exposure to air - why it is difficult to solder. The aluminum oxide is not whetted by solder. Aluminum oxide is a ceramic, called Alumina. Anodized aluminum has has a thick layer of aluminum oxide formed on its surface

- Q: and alsoHow many grams of the decay product will have formed after 8 days go by?The decay product is the new isotope created as a result of the positron decay of aluminum-24.In class my teacher didn't explain this completely but there's a question on the homework that me and even my mom (another teacher) can't find the answer to.

- so it 6000/ (2*8*24*60*60) 0.00434027778 grams have you heard of the internet an unless your mom is a chem teacher it doesnt mean much

- Q: What are the factors that determine the price of aluminum coils?

- There are several factors that determine the price of aluminum coils. One of the main factors is the cost of raw materials. The price of aluminum is influenced by factors such as supply and demand, global economic conditions, and production costs. Fluctuations in these factors can directly impact the price of aluminum coils. Another factor that determines the price of aluminum coils is the manufacturing process. The cost of processing aluminum into coils involves various expenses such as labor, energy, and equipment. The complexity of the manufacturing process and the efficiency of the production line can affect the overall cost, which in turn influences the price of aluminum coils. Market conditions also play a crucial role in determining the price of aluminum coils. Factors such as market competition, industry trends, and geographic location can impact pricing. For instance, if there is a high demand for aluminum coils in a particular region but limited supply, the price may increase due to the scarcity of the product. Additionally, transportation and logistics costs contribute to the final price of aluminum coils. The distance between the manufacturing facility and the customer, as well as the mode of transportation, can affect the shipping expenses. These costs are typically factored into the overall price of the coils. Lastly, government policies and regulations can influence the price of aluminum coils. Tariffs, import taxes, and trade agreements may impact the cost of importing or exporting aluminum coils, thereby affecting the final price. In conclusion, the price of aluminum coils is determined by various factors including the cost of raw materials, manufacturing processes, market conditions, transportation costs, and government policies. It is essential for manufacturers and consumers to consider these factors when analyzing and forecasting the price of aluminum coils.

- Q: Im trying to make a aluminum ring. I want it to be rock hard. PLZZAnswers that work get best answer

- use a hard alloy like 7075 and heat treat it

- Q: Does anyone know of any men's deodorant that doesn't contain aluminum? It has to be strong, as I do sweat a lot.

- Both my Speed Stick Original Scent and Old Spice High Endurance Original contain no Aluminum. They are both deodorants, NOT antiperspirants, which work differently. Deodorants do not inhibit sweating, they just keep you from smelling funky from it. Hence the name DEodorant. Antiperspirants on the other hand DO inhibit sweating as well as keep you smelling fresh. They do so by clogging your pores! And if there is aluminum in it, it can cause irritation on some people. Most antiperspirants contain aluminum, most deodorants do not. Whichever you end up going with just read the back label.

- Q: Can aluminum coils be used in coil coating processes?

- Yes, aluminum coils can be used in coil coating processes. Aluminum is a commonly used material for coil coating due to its durability, lightweight nature, and resistance to corrosion. It can be easily coated with various finishes and colors, making it suitable for a wide range of applications in industries such as construction, automotive, and appliances.

Send your message to us

China Color Coated Aluminum Coil - Aluminium Profile Glass Wall Usage with Best Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords