China Aluminum Coil Price - Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

Thickness | 0.1mm-10mm |

Popular Thickness | 0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm... |

Width | 20mm-2500mm |

inner diameter | 505mm 508mm 605mm |

Material | 1050,1060,1070,1100,1200,3003,3004,3005,5052,5005,5754,5083 |

Temper | O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112 |

Surface | mill finish |

Packing | Export standard wooden pallets |

Payment Terms | 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy |

Minimum Order Quantity | 5000kg |

Delivery time | 15-25 days after receiving L/C or deposit |

Remark | Specific requirement of alloy grade, temper or specification can be discussed at your request |

2. Application of Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

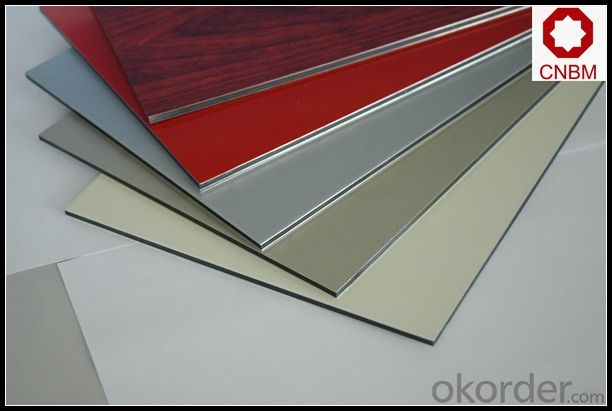

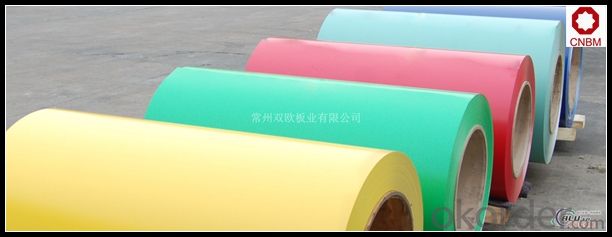

5. Image of Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

6. Package and shipping of Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum coils be used for food processing conveyor systems?

- Yes, aluminum coils can be used for food processing conveyor systems. Aluminum is a durable and lightweight material that is resistant to corrosion, making it suitable for food processing environments. Additionally, aluminum is non-toxic and does not react with food, ensuring the safety and quality of the processed products.

- Q: What are aluminum coils?

- Aluminum coils, wound in a spiral shape, are thin and flat pieces of aluminum. Their versatility and durability make them commonly utilized in various industries. These coils are typically crafted from high-quality aluminum alloy, which grants them qualities such as lightweight, corrosion resistance, and ease of manipulation. A wide range of applications, including building and construction, automotive manufacturing, electrical appliances, and packaging, benefit from the use of aluminum coils. Depending on the specific requirements of the industry or product, these coils can be further processed into different forms, such as sheets, foils, or strips. Altogether, aluminum coils are crucial components in numerous manufacturing processes and play an essential role in diverse industries.

- Q: How are aluminum coils tested for surface cleanliness?

- Aluminum coils are tested for surface cleanliness through various methods and techniques to ensure that they meet the required standards. One common method used is the water break test. In this test, a clean water droplet is placed on the surface of the aluminum coil. If the water spreads out evenly and forms a continuous film without beading or breaking, it indicates that the surface is clean and free from any contaminants. Another method used is the solvent wipe test. In this test, a solvent-soaked wipe is gently rubbed on the surface of the aluminum coil. The wipe is then inspected for any dirt or residue that may have been picked up, indicating the presence of contaminants on the surface. Surface energy measurement is also carried out to test the cleanliness of aluminum coils. This involves measuring the surface energy of the coil using a contact angle measurement device. If the surface energy is high, it indicates a clean surface, whereas a low surface energy suggests the presence of contaminants. In addition, visual inspection is often conducted to check for any visible dirt, oil, or other foreign substances on the surface of the aluminum coil. This can be done using a magnifying glass or under specific lighting conditions to ensure thorough examination. Overall, a combination of these methods is used to assess the cleanliness of aluminum coils, ensuring that they are free from contaminants and suitable for further processing or use in various industries.

- Q: How are aluminum coils used in the production of signage and displays?

- Aluminum coils are widely used in the production of signage and displays due to their versatility, durability, and cost-effectiveness. These coils are typically made from high-quality aluminum alloy, which provides excellent strength and resistance to corrosion. In the production process, aluminum coils are first unwound and then passed through a series of rollers to achieve the desired thickness and shape. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the surface of the aluminum. These coatings can include polyester, polyurethane, fluorocarbon, or acrylic, depending on the specific requirements of the signage or display. Once the aluminum coils are coated, they can be further processed into different forms, such as flat sheets, strips, or even customized shapes based on the design requirements. The versatility of aluminum allows for easy fabrication and customization, making it a popular choice for signage and display manufacturers. Aluminum coils are commonly used in a wide range of signage applications, including billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum makes it easy to transport and install, reducing production and installation costs. Moreover, aluminum's durability ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. The corrosion-resistant properties of aluminum also contribute to the longevity of the signage, ensuring that it maintains its appearance and functionality over time. In addition to its physical properties, aluminum's aesthetic appeal is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, helping to grab attention and communicate messages effectively. Overall, aluminum coils play a crucial role in the production of signage and displays by offering versatility, durability, cost-effectiveness, and aesthetic appeal. Their ability to be easily customized, combined with their resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating eye-catching and long-lasting signage and display solutions.

- Q: Are aluminum coils easy to install?

- Yes, aluminum coils are generally easy to install. They are lightweight and flexible, which makes them easier to handle and maneuver during installation. They can be easily cut and shaped to fit the specific requirements of the installation, and they are often available in pre-cut sizes, further simplifying the installation process. Additionally, aluminum coils are typically designed with features such as interlocking edges or snap-on connectors, which make it easier to join multiple coils together or connect them to other components. Overall, with the right tools and basic knowledge of HVAC installation, aluminum coils can be installed relatively easily.

- Q: What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to the inherent properties of aluminum as a malleable and ductile material. Aluminum is known for its high strength-to-weight ratio, which allows it to be easily shaped and formed without compromising its structural integrity. When it comes to bending, aluminum coils can be bent into various shapes and angles without fracturing or cracking. The flexibility of aluminum allows it to be formed into tight curves or gentle bends, making it suitable for a wide range of applications. This flexibility is particularly advantageous in industries such as construction, automotive, and aerospace, where curved or complex shapes are often required. In terms of forming, aluminum coils can be easily manipulated into different forms, including flat sheets, tubes, or intricate profiles. This versatility makes aluminum coils highly sought after in industries where customization and design flexibility are important. Furthermore, aluminum coils can undergo various forming processes such as roll forming, stamping, and deep drawing, allowing them to be transformed into different products with precise dimensions and tolerances. These forming capabilities make aluminum coils a preferred choice for manufacturing components, such as automotive body panels, roofing materials, heat exchangers, and structural elements. Overall, the bending and forming capabilities of aluminum coils are exceptional, making them an ideal choice for applications that require flexibility, durability, and design versatility.

- Q: How are aluminum coils priced?

- Aluminum coils are typically priced based on various factors such as the current market price of aluminum, the size and thickness of the coil, the quantity ordered, and any additional customization or processing requirements. Additionally, factors like transportation costs and market demand can also influence the pricing of aluminum coils.

- Q: How much fluorocarbon and polyester paint should be used in production of aluminum coil and aluminum-plastic panel?

- The theoretical calculation is very complicated and far from actual result. In general, the manufacturer knows how much area and how thick their products can be painted.

- Q: What are the potential challenges in recycling aluminum coils?

- There are several potential challenges in recycling aluminum coils. Firstly, aluminum coils often contain contaminants such as paint, oil, or other coatings that need to be removed before the recycling process can take place. This can be a time-consuming and costly process, as the coils need to be thoroughly cleaned to ensure the quality of the recycled aluminum. Secondly, aluminum coils are often mixed with other materials such as steel or plastic, which further complicates the recycling process. These materials need to be separated from the aluminum before it can be melted down and recycled. This separation process requires specialized equipment and expertise, adding to the overall cost and complexity of recycling aluminum coils. Another challenge is the transportation and logistics involved in recycling aluminum coils. These coils are often large and heavy, making it difficult and expensive to transport them to recycling facilities. Additionally, the recycling facilities themselves need to have the necessary infrastructure to handle and process these coils efficiently. Moreover, the fluctuating market prices of aluminum can also pose a challenge in recycling aluminum coils. The value of recycled aluminum is influenced by factors such as global supply and demand, which can vary significantly over time. This can make it difficult for recyclers to accurately predict the financial returns from recycling aluminum coils, potentially affecting the viability of the recycling process. Lastly, the overall awareness and participation in aluminum coil recycling can be a challenge. Many industries or individuals may not be aware of the benefits of recycling aluminum coils or may not have access to recycling facilities. Increasing education and accessibility to recycling programs can help overcome this challenge and promote the sustainable recycling of aluminum coils.

- Q: I've heard many times that it's unhealthy to store or cook food in aluminum, due to leaching, but will this apply to handling aluminum. Also, I heard that most aluminum is coated with a layer of something, to prevent oxidation; is this true?

- Pure soft shiny aluminum develops a thin tenacious layer of aluminum oxide that retards further oxidation (unless worn off). The outer layer of skin is dead horny matter that resists penetration by metal atoms. However, some people do develop allergies to metals and perhaps metals dissolved in sweat (acids?) may get through to live tissue. Handling aluminum may not have been proved harmful but skeptics likely will take less chances.

Send your message to us

China Aluminum Coil Price - Color Coated Aluminum Coil for Decoration, Aluminum Coated Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords