China Aluminium Ceiling Panels - Color Coated Aluminum Coil Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

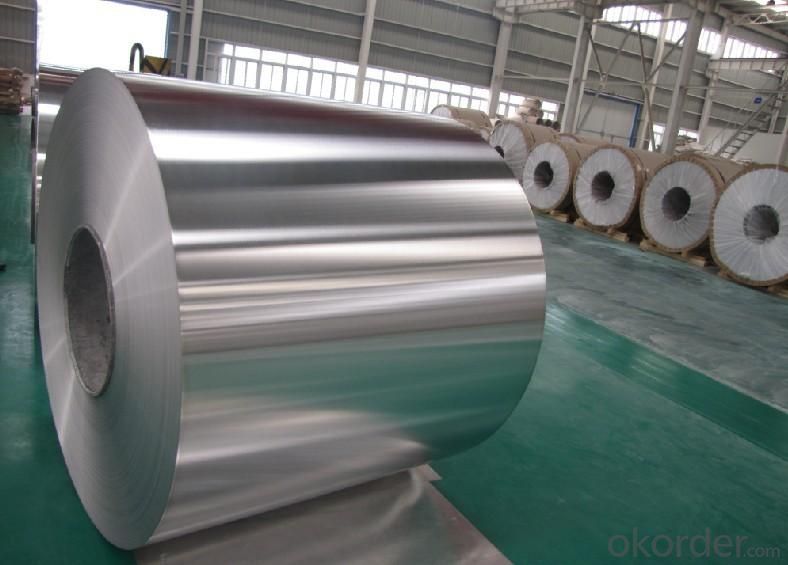

Color Coated Aluminum Coil Aluminum Alloy

1. Grade

| Series: | 1100 etc. |

| Series: | 3003 3004 3005 etc. |

| Series: | 5006, 5052 |

| Series: | 8011 etc. |

2. Thickness

| Plate Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

| Coil Thickness | 0.1mm, 0.12mm,0.15mm,0.20mm,0.25mm,0.28mm,0.3mm,0.35mm,0.38mm, 0.4mm,0.5mm, 0.53mm, 0.58mm,0.68mm,0.7omm,0.73mm,0.75mm, 0.90mm, 1mm, 1.2mm |

3. Description

Alloy | AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc , etc. |

Temper | H16, H18, H24, H26, H28 |

Thickness | From 0.1mm to 1.2mm |

Width | Standard width:1240mm, 1270MM |

Special width:1000mm, 1200mm, 1240mm, 1270mm, 1520mm, 1620mm | |

Diameter | Standard dia:1200mm |

Interior dia: 150mm,405mm, 500mm, 505mm, 510mm | |

outer diameter: 1200mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating thickness | PE:>=16 micron , PVDF:>=25 micron |

Protective film | As per customer’s request |

Coating paint | PVDF, PE(Polyester), epoxy, polyamide, polyurethane |

Color | Soid, metallic, high gloss,stone,timber,brush,mirror,sparkling, RAL or by customer requirements. |

Weight | As per customer’s request |

| Surface | Embossed, mill finish, coated |

| Gloss | 10-100% |

| Coating Hardness (pencil resistance) | More than 2h |

| Coating adhesion | 1J |

| Impact Resistance | No peeling or cracking(50 kg/cm) |

| Application | ACP,wall cladding,facades,roofs and canopies,ceilings,signboards,blind window,display platforms,electrical panels,etc |

| Coating Thickness | PE coating:more than 16 micron |

| PVDF coating:more than 25micron |

4. FAQ

1.Q: What about leadtime ?

A: Normally the leadtime is 60days after we receive the deposit and confirm the details. All the press machines we use is the best quality in China Yangli brand. The press machine leadtime from Yangli is 50days, the best leadtime we can give is 60days.

2.Q: What's the lead time for moulds?

A: Normally the mould leadtime is 45 days after we confirm all the details with customer. Our professional mechanical enginners from Austria will design the mould according to the samples from customer, or by the specifications offered by customers.

3.Q:What kinds of mould you can make? and what is your strong point for the moulds?

A: we can make wrinkle wall mould and smooth wall mould both. For wrinkle wall mould we can make, 79" pan, fish pan, bbq pan. For smooth wall mould we can make muffin cup, and cake cup, tar cup,etc. We can also make 2 or 3 portion conatiner moulds as long as you offer us sample or specifications. Our strong points are all our moulds are WEDMLS cut, which makes the mould more accurate and precise. Important materials likestainless steel parts we make in Austria. We also recut after heat treatment, which most of makers do not take this process.

- Q: Interior decoration often use the strip of aluminum slabs have any specifications of the profile. Often the market is how long and how long to sell? Thank you! The The Usually the kitchen, bathroom, corridor ceiling with.

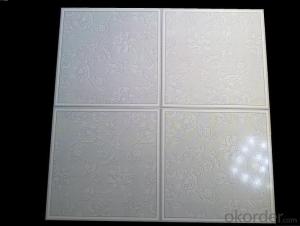

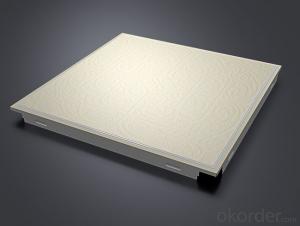

- Metal (aluminum slab plate) ceiling in recent years only appeared and popular, it has become the darling of the kitchen darling. Compared with the traditional materials, metal ceiling with elegant color and diverse, three-dimensional sense of strong, decorative effect, and other decorative materials, such as tiles, marble, etc. can form a very coordinated overall decorative effect. Metal ceiling fire, waterproof performance, light material, high strength, easy aging, easy installation, with good sound absorption, sound insulation performance, as well as easy to clean fume, long life, easy deformation and other advantages. Specifications: width: 100 200 300 mm thick: 0.6 ~ 1.0 mm long: 600 ~ 1200 (the family for the length, but also the length of processing)

- Q: Is the size of the downlight on the ceiling of the aluminum slab plate the same as the size of the normal downlight? How do I install the downlight if I buy the aluminum plate?

- After the installation of the aluminum plate, before the installation, you need to determine the diameter of the downlight (hole size), and the location of the hole, and then install the aluminum plate when the lamp directly out of the hole Can be used to open the hole with a knife.

- Q: Aluminum veneer, aluminum buckle plate price What is the difference? What are the specifications?

- Aluminum veneer The use of high-quality aluminum alloy panel for the substrate, advanced CNC bending technology to ensure that the plate can be formed after the deformation is not deformed in the installation process of anti-external performance superior; Surface coating using the United States flange water fluorocarbon spraying equipment and the United States Aksu Fluorocarbon (PVDF) coating to ensure uniform surface color, anti-ultraviolet radiation, anti-oxidation, super corrosion resistance. The use of aluminum veneer Building curtain wall, column beam, balcony, partition package decoration, outdoor decoration, advertising signs, vehicles, furniture, booth, equipment shell, subway shipping tools. The aluminum plate is divided into the following categories: The first type of aluminum-magnesium alloy, containing some of the manganese, the biggest advantage of the material is good antioxidant capacity, and because the addition of the amount of manganese, in strength and stiffness has improved, is the best material ceiling; The second type of aluminum - manganese alloy, the strength and stiffness of the plate is slightly better than the aluminum - magnesium alloy, but the antioxidant capacity is slightly inadequate; The third type of aluminum alloy, the plate contains manganese, magnesium less, so its strength and stiffness are significantly lower than the aluminum-magnesium alloy and aluminum-manganese alloy, antioxidant capacity in general. Mainly used for ceiling ceiling

- Q: Kitchen bathroom aluminum plate to the top of the original distance is generally how much?

- I am a professional staff engaged in decorative design and construction for many years, you should not ask the question asked, but mainly to see your kitchen and bathroom at the top of the specific circumstances of the pipe, if the pipeline is lower than the regular life Habit of height, then the lowest point of the pipeline for the aluminum plate hanging ceiling, unless you can change the pipeline to a little change. From the decorative point of view, now the housing construction developers generally clean height between the kitchen and toilet in the 2.65-2.70 meters or so, to remove the floor tiles laying height of about 5 cm, and then the ground and the top of the height control in 2.4 Rice height for the best height, in fact, this is also in line with the principles of Asian human biology, but also in line with the Asian living habits, like the kitchen under the cabinet about 80 cm or so, the middle empty about 80 cm, OTC and fumes About 80 centimeters or so, so there is a conventional 2.4 meters.

- Q: Will the bathroom ceiling plate installed on the ceiling (top grade) is not bright, how to change the light bulb? Kouban can be removed, the light can not get down.

- General aluminum buckle long lights are H tube or T4, these two are plugging tube, whether it is the kind of just looking for the head, and then grabbed his head down like this is long. Side of the ring tube, there is three cards with the card, the card opened on the OK. Aluminum button for the lamp is not unloading the base of the lamp.

- Q: Kitchen wall paste tile master only posted 2.2 meters high, he went back home. I would like to do stacked ceiling, do not know 300 * 300 aluminum buckle plate can do stacking ceiling? Thank you!

- Usually called the level of ceiling, or a secondary ceiling.

- Q: Buy aluminum plate, need to pay attention to what

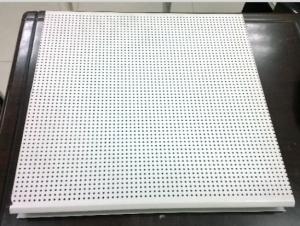

- Aluminum plate with a micro-punching board, some people recommend the use of the bathroom, that is able to moisture. I think the reason for the drop of water is: when the water will rise when the bath, by the ceiling block, will be in the aluminum plate under the surface of the condensate into a small water droplets, after bath to open the bathroom, cold air into the water droplets become more and more dew. With the use of micro-punching aluminum plate, the steam can be through the micro-punching into the top of the ceiling, condensed into water droplets, due to the surface tension of water, can not pass through the micro-punching, only slowly above the ceiling evaporation. But if we look at the bathroom as a whole, with the micro-punching of the aluminum plate is only a place to move the moisture, and can not solve the problem of moisture, but will make the top part of the ceiling more humid. Now the bathroom is generally by Yuba, exhaust fan row of tide, electrical fear of the tide, the use of micro-punching with the aluminum plate instead of the use of electrical appliances.

- Q: How to distinguish between aluminum plate and what kind of board board

- The difference is that the surface coating is different, the lowest price of film, followed by rolling, and then the next nano. General home improvement, roller the most appropriate. If you pay attention to style with the general European-style idiots with nano-aluminum plate, modern with roller coated aluminum plate. Laminating has been useless, because easy to oxidize discoloration, according to your price on-demand purchase, personal opinion of the kind of high-end oxidation is not necessary, that is to cover a ugly, good clean fumes.

- Q: Are there any differences between the ceiling and the Laminates? Is the price the same?

- As long as the plate material is aluminum, all called aluminum plate. Laminating plate, refers to the main material outside the adhesion of a layer of protective material. There are many kinds of laminating plates, the mainstream of the film board containing PVC coated board and aluminum slab plate coated two. Laminated film because of their own technical limitations, inevitably there will be a bubble phenomenon, this is absolutely unavoidable. At the same time according to the difference between the film material, poor material turned yellow year, a good material for three years will change color. So now the mainstream products are the main roller-based, laminating board has not been accepted by everyone.

- Q: Mirror aluminum plate and nano-aluminum plate which is good

- One is to see what you want to hang in the location

Send your message to us

China Aluminium Ceiling Panels - Color Coated Aluminum Coil Aluminum Alloy

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords