Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 10-20days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Specifications | Width: 30cm,38cm,45cm, OEM; Length: 3m-20m, OEM; Thickness: 10mic-20mic(10mic=10um=0.01mm), OEM; Sizes can be customized according to your requirement; |

| Application |

Supermarkets, catering, hotel, airline, restaurants, household, medical,electronic,chocolate wrapping etc;

|

| Characteristic | 1. Use: suitable for the food packing, barbecue; 2. Color: for food only do sliver color; 3. Inner packing : paper roll core; 4. Box with metal cutter; 5. Surface packing: Color box; |

| NOTES | Our factory can quote to you at the specifications that what you want any time. To undertake all kinds of plastic processing operations. Any sizes and packing can be ordered. Good service and reasonable price.

|

FAQ

1. How can I get some samples?

We are honored to offer you samples. New clients are expected to pay for the courier cost. The samples are free for you.

2 Do you have any certificates?

Our products passed inspection of SGS, FDA, and CE Quality is priority! Every worker keeps the QC from the very beginning to the very end, Quality control department especially responsible for quality checking in each process.

3 Can your factory print or emboss my logo on the goods?

Yes, we can print or emboss the logo on the goods or their packing box.

4 What information should I let you know if I want to get a quotation?

1) The specification of products (length x width x thickness);

2) The temper and alloy.

3) The final product you will use to be made

4 It will be better if you can show us the pictures or design sketch. Samples will be best for clarifying. If not, we will recommend relevant products with details for reference.We usually produce goods based on customers

Samples or based on customers’ picture, logo, sizes etc.

Our Services

1. Reasonable production arrangement to make delivery very fast;

2. We are able to provide leading tolerances, metallurgical assistance, quick and reliable delivery, samples for new products, etc.

3. We have the strong capability to meet your particular requirement for the products.

4.To guarantee the quality of the products we can meet most of the standards all over the world.

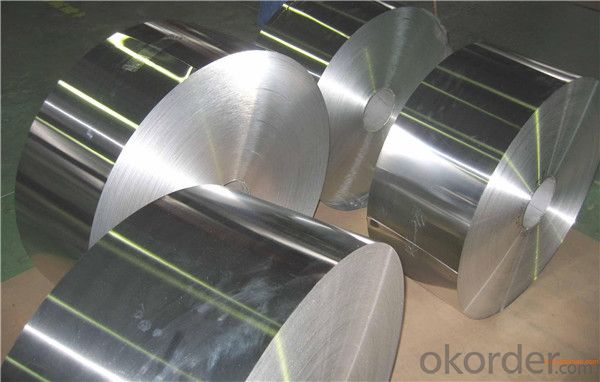

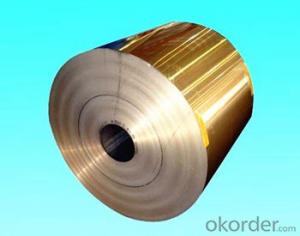

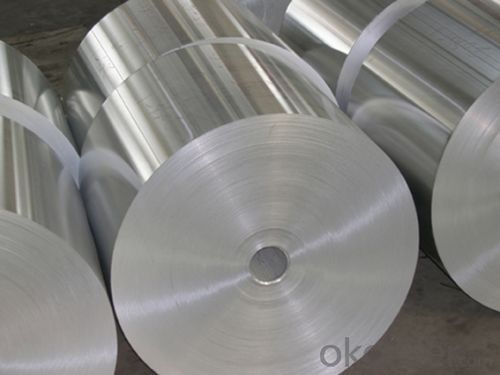

Photos

- Q: Well, we've got the existing old school 7 layers of peeling yucky painted siding and we're trying to weigh our options. So here's my questions:1) Is it cost effective to replace Aluminum with Vinyl?2) Is Vinyl truly as costly as we keep hearing? **Home is small 1,100 sq.ft with a 2.5 car Garage**3) Is painting this existing siding a wise choice since the current paint job on it looks terrible? We just need to make it more a home, right now it's gorgeously all new and redone inside and on the outside it still resembles the day we bought it in forclosure. Aside from my green grass I busted my butt on last summer.Please advise.

- Aluminum Siding Vs Vinyl Siding

- Q: What are the fire resistance properties of aluminum coils?

- Aluminum coils have excellent fire resistance properties due to the inherent characteristics of aluminum, such as its high melting point and low flammability. Aluminum does not burn, but instead forms a protective oxide layer on its surface when exposed to heat or flames. This oxide layer serves as a barrier, preventing further oxidation and combustion. Additionally, aluminum has a high thermal conductivity, which helps to dissipate heat quickly, further reducing the risk of fire. Overall, aluminum coils are considered to be highly resistant to fire.

- Q: What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to their inherent flexibility and malleability. They can be easily bent, shaped, and formed into various complex shapes and designs without losing their structural integrity. This makes them highly versatile and suitable for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

- Q: How to calculate the length of aluminum sheet with the thickness known?

- Thickness*width*length=weight/density, length=weight/(density*thickness*width). Ps: Keep unit the same.

- Q: How do aluminum coils contribute to the corrosion resistance of marine applications?

- The corrosion resistance of marine applications is greatly improved by aluminum coils, thanks to the unique properties and characteristics of aluminum as a material. To begin with, aluminum naturally forms an oxide layer on its surface when it comes into contact with air. This oxide layer is highly resistant to corrosion and acts as a protective barrier to prevent further oxidation and corrosion of the metal. This inherent property of aluminum makes it an excellent choice for marine applications, where constant exposure to saltwater and moisture can be extremely corrosive. In addition, aluminum coils can be alloyed with elements like magnesium and manganese to further enhance their corrosion resistance. These alloying elements not only strengthen the aluminum but also improve its resistance to pitting and crevice corrosion. Pitting corrosion occurs when localized damage exposes the underlying metal, while crevice corrosion occurs in areas with restricted oxygen flow, such as gaps or joints. By alloying aluminum, the coils become more resistant to these types of corrosion, making them highly suitable for marine environments. Furthermore, aluminum coils can be coated with protective finishes such as anodizing or painting, which provide an extra layer of defense against corrosion. Anodizing involves creating a thicker and more durable oxide layer on the aluminum surface, thereby increasing its resistance to corrosion. On the other hand, painting acts as a physical barrier that shields the coils from direct contact with corrosive elements present in the marine environment. In conclusion, aluminum coils contribute to the corrosion resistance of marine applications through the presence of a natural oxide layer, alloying with other elements, and the option of protective finishes. These characteristics ensure that aluminum coils are highly durable and capable of withstanding the challenging conditions encountered in marine environments, guaranteeing their longevity and reliability.

- Q: what is aluminium toxic amount on a human's general physiological system? and what is the usual amount aluminium injested?thankyou

- Go okorder /

- Q: A piece of aluminum foil 0.550 mm thick and 1.00 cm square is allowed to react with bromine to form aluminum bromide?a) How many mole of aluminum were used? ( The density of aluminum is 2.699 g/cm3.)I keep getting the same answer which I know is wrong. I used a formula to get the volume and then the mass to get the moles, but maybe this is wrong. Could someone explain the process. I got 4.32 x 10-1 mol Al, but the answer is 5.50 x 10-3 mol Al.

- Okay. If you have .55mm thick, 1cm square of Al, you you have 55 cubic mm of Al. 55 cubic mm is .055 cubic centimeters of Al. .055 * denisty of Al (2.699 g/cm3) gives you .148 grams of Al. Al molecule weight is 27g/mole. So .148 g * (1 mole / 27 grams) = .00548 moles of Aluminum. That rounds to about 5.50 x 10-3 moles. I should also add that A) Remember when you are converting cubic units (such as mm3 into cm3), the conversion factor should also be cubed (so 1 cubic mm = 10^3 cubic cm). Also, not to be nit picky, but this question is dumb because aluminum foil would also have a good portion of aluminum oxide coating it...but I wouldn't bring that up to the teacher if I were you. :-)

- Q: What does it mean to slice aluminum coil by decoiler machine?

- The operating procedures of decoiler machine: 1, Select appropriate aluminum coil according to production work order requirement to be processed, paying attention to the thickness, width and material of aluminum coil. 2, Put the aluminum coil into the coil loading car with traveling crane and inch the car into the uncoiler. The aluminum coil and decoiler machine should be in the same direction. Hold the aluminum coil down with leading head, and open the auxiliary bearing. 3, Turn on the shovel head, and inch the uncoiler to lead the aluminum sheet into the leveler. Adjust the leveler according to the thickness and width of aluminum sheet to ensure the flatness. 4, Turn on the front gap bridge and back gap bridge in control main platform, inch the leveler to lead aluminum sheet into re-leveler. Adjust the re-leveler to ensure the flatness of aluminum sheet. Put it into the shear gauge and plate shearer. 5, Take back the front and back gap bridge. Inch the plate shearer to cut off the sheet head and shear the aluminum sheet according to production work order. Check the first sheet to see whether it meets the quality standard and whether there is defect in flatness, length, diagonal, and surface of aluminum sheet. If it is qualified, turn on the conveyor. Put the aluminum sheet holder on the pallet. Adjust the pallet according to the width and length of aluminum sheet. Input quantity and length on the control main platform. Then turn on the auto control to produce automatically. The production process can be observed at any time. 6, If there is aluminum coil left, unwind, package and put it into storage in reverse steps.

- Q: Can aluminum coils be used in the production of aluminum windows?

- Yes, aluminum coils can be used in the production of aluminum windows. Aluminum coils are often used as a raw material in the manufacturing process of aluminum windows. These coils are typically made from high-quality aluminum and are rolled into thin, flat sheets. These sheets can then be cut and shaped into the desired frame size and design for the windows. Aluminum is a popular material for window frames due to its durability, lightweight nature, and resistance to corrosion. The use of aluminum coils in the production of aluminum windows allows for efficient and cost-effective manufacturing processes while also providing a high-quality end product.

- Q: How are aluminum coils stored and transported?

- To ensure the safety and minimize damage of aluminum coils, they are stored and transported in a manner that prioritizes their well-being. Generally, these coils find their place in a warehouse or storage facility, where they are shielded from external elements and potential hazards. They are neatly stacked, taking into account security, and are safeguarded against movement or potential harm by proper padding or spacers. When it comes to transportation, aluminum coils are typically carried in flatbed trucks or shipping containers. These vehicles are equipped with secure tie-downs and restraints that prevent any shifting or damage during transit. It is crucial to ensure the proper securing of the coils to avoid any accidents or mishaps. Moreover, additional precautions are taken during transportation to protect the aluminum coils from potential harm. For instance, the coils may be shielded with protective materials like plastic or fabric, which prevent scratches or dents. In some cases, stretch film or bands may be used to provide extra protection by wrapping or strapping the coils. In summary, the storage and transportation of aluminum coils necessitate careful handling and adherence to safety protocols. This guarantees that the coils maintain their optimal condition and reach their destination without any complications.

Send your message to us

Aluminum Coils for Air Conditioners - Aaluminum Foil Induction Seal Liner for HDPE and PET Packers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords