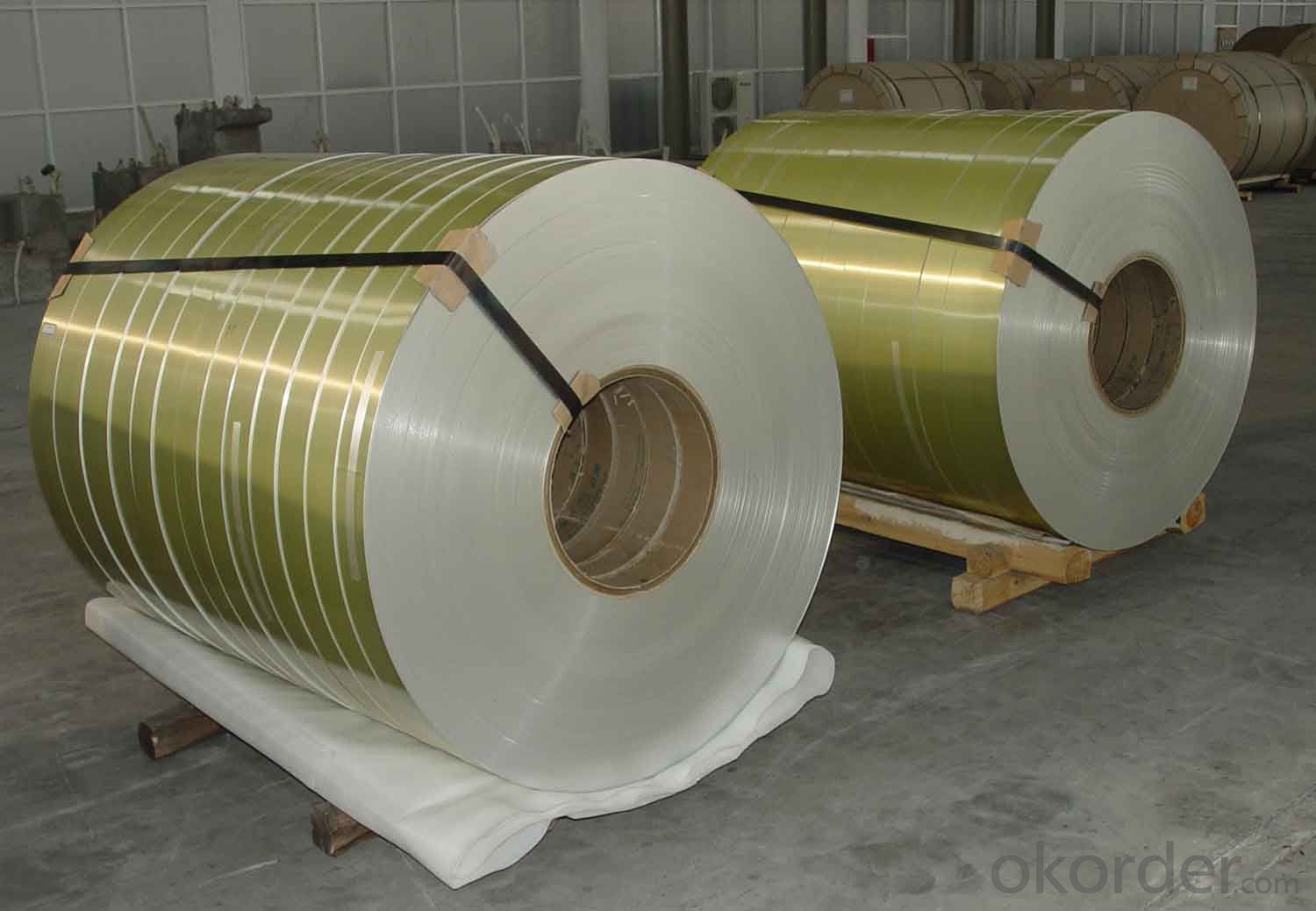

Aluminum Curtain Wall Coil - China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

Alloy: 5052(AlMg2.5)

Temper: O,H12,H22,H32,H14,H24,H34,H16,H26,H36,H18,H38,F

CHEMICAL COMPOSITION LIMITS (%)

Silicon | Iron | Copper | Manganese | Magnesium | Chromium | Nickel | Zinc | Titanium | Others | Total | Aluminum |

0.25 | 0.4 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.05 | 0.15 |

Remainder |

Main application: Magnesium gives this alloy its enhanced corrosion resistance, workability, strength and weldability. Typical uses include aircraft fuel tanks, container body, truck/trailer body, electronic mounting plates and panels, fan blades, refrigeration liners, storm shutters and utensils.

Mechanical Property Limits

Alloy | Temper | Thickness(mm) | Tensile Strength(MPa) | Elg%(50mm) |

5052 | O | >0.5-0.8 >0.8-1.3 >1.3-6.5 >6.5-10.0 | 170-215

| ≥15 ≥17 ≥19 ≥18 |

H12/H22/H32 | >0.5-1.3 >1.3-4.5 | 215-265 | ≥5 ≥7 | |

H14/H24/H34 | >0.5-0.8 >0.8-1.3 >1.3-4.5 | 235-285 | ≥3 ≥4 ≥6 | |

H16/H26/H36 | >0.5-0.8 >0.8-4.5 | 255-305 | ≥3 ≥4 | |

H18/H38 | >0.5-0.8 >0.8-4.5 | ≥270 | ≥3 ≥4 | |

H112 | >4.5-6.5 | ≥195 | ≥9 ≥7 | |

>6.5-12.5 | ≥195 | |||

>12.5-40.0 | ≥175 | |||

>40.0-80.0 | ≥175 |

Our Services

Payment: by 30%T/T in advance and balance before shipment or 100% L/C at sight

Delivery: within 30 days after we get your deposit or L/C.

Packing: sea worthy wooden pallet

Loading port: Qingdao/Shanghai/Tianjin, China

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: Is it possible to utilize recycled aluminum in the production of new products more efficiently than current methods?

- <p>Yes, recycled aluminum can be used more effectively in new products than before. Advances in recycling technology have made it easier to purify and refine aluminum from various sources, including post-consumer waste. This not only conserves natural resources but also reduces energy consumption compared to mining and processing raw bauxite. Additionally, the circular economy approach promotes the design of products that are easier to disassemble and recycle, further enhancing the efficiency of using recycled aluminum in new products.</p>

- Q: Explain how the addition of zinc impacts the corrosion resistance of aluminum alloys.

- <p>The addition of zinc to aluminum alloys significantly enhances their corrosion resistance. Zinc forms a protective layer on the surface of aluminum, which prevents the metal from reacting with corrosive elements such as oxygen and moisture. This protective layer, known as a passive layer, is self-healing and can regenerate if damaged, maintaining its effectiveness over time. Additionally, zinc's presence in aluminum alloys can improve the alloy's overall mechanical properties, making it more resistant to stress corrosion cracking. This is particularly useful in marine environments or other corrosive conditions where aluminum alloys are commonly used.</p>

- Q: This question asks for examples of alloys that have a significant amount of aluminum and are known for their strength and ductility.

- <p>Alloys that are known for their high aluminum content and possess excellent strength and ductility include 6061 aluminum alloy, 7075 aluminum alloy, and 2024 aluminum alloy. 6061 is widely used in structural applications due to its balance of strength, corrosion resistance, and formability. 7075 is one of the strongest aluminum alloys and is used in aerospace and high-strength applications. 2024 is known for its good mechanical properties and is used in aircraft structures and other demanding applications. These alloys leverage the benefits of aluminum, such as low density and high resistance to corrosion, while their specific compositions and heat treatments enhance their strength and ductility.</p>

- Q: Is aluminum a suitable material for use in nuclear power plants?

- <p>Yes, aluminum can be used in nuclear power plants, but its application is limited due to its reactivity with neutrons. Aluminum is used in non-nuclear grade components such as cooling systems, electrical equipment, and structural supports. However, it is not used in the core or in high-radiation areas due to its tendency to absorb neutrons, which can lead to transmutation and the production of radioactive isotopes. Materials like stainless steel, zirconium alloys, and other neutron-resistant materials are preferred for core components and high-radiation environments.</p>

- Q: Is it possible to recycle aluminum and what are the benefits of doing so?

- <p>Yes, aluminum can be recycled, and it is one of the most recycled materials in the world. Recycling aluminum saves up to 95% of the energy needed to produce new aluminum from raw materials. It also reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum can be used in various applications, from beverage cans to construction materials, making it an environmentally friendly and economical choice.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: This question asks for the current cost of aluminum.

- <p>The cost of aluminum fluctuates based on market conditions and can vary by region. As of my last update, the price of aluminum was around $2,500 per metric ton, but this is subject to change. For the most accurate and up-to-date pricing, it's best to check with a commodity exchange or a reliable financial news source. Prices can be influenced by supply and demand, economic indicators, and geopolitical factors.</p>

- Q: This question asks for typical applications of aluminum foil in everyday life.

- <p>Aluminum foil is commonly used for food storage, as it helps preserve freshness and prevents freezer burn. It's also used in cooking, either to cover dishes to retain moisture or to create packets for steaming or baking. In the kitchen, it's often used to line baking sheets to prevent food from sticking. Beyond cooking, aluminum foil is used for insulation, in arts and crafts, and even for cleaning purposes, such as buffing glass or polishing silverware. It's a versatile material found in many households and commercial settings.</p>

- Q: What are the various electronic components that utilize aluminum as a primary material?

- <p>Aluminum is used in several types of electronic components due to its good thermal conductivity, lightweight, and corrosion resistance. Some of the common components include: 1. Capacitors: Aluminum electrolytic capacitors are widely used for their high capacitance and low cost. 2. Heat sinks: Aluminum is a popular choice for heat sinks due to its ability to dissipate heat efficiently. 3. Semiconductors: Aluminum is used in semiconductor manufacturing, particularly for interconnects and as a barrier layer. 4. Conductive adhesives: Aluminum-filled adhesives are used for bonding components in electronics. 5. Wires and cables: Aluminum wire is used in some applications due to its lower weight compared to copper. 6. Reflectors: Aluminum is used in light reflectors for its reflective properties. 7. Housings and enclosures: Aluminum is used in the construction of electronic device casings for its strength and lightweight properties.</p>

Send your message to us

Aluminum Curtain Wall Coil - China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords