Customized Coated Aluminum Coil for Aluminium Alloy Profile for Window and Door in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminium Alloy Profile for Window and Door Description:

Aluminium Alloy Profile for Window and Door(also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Alloy Profile for Window and Door:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

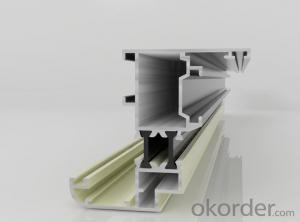

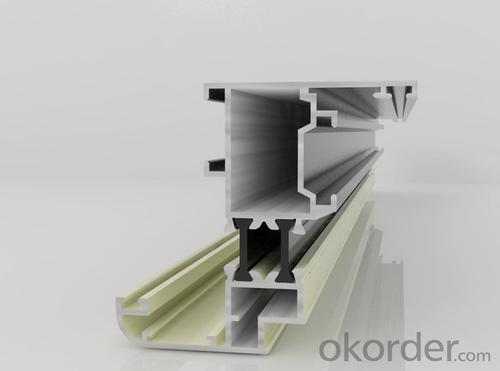

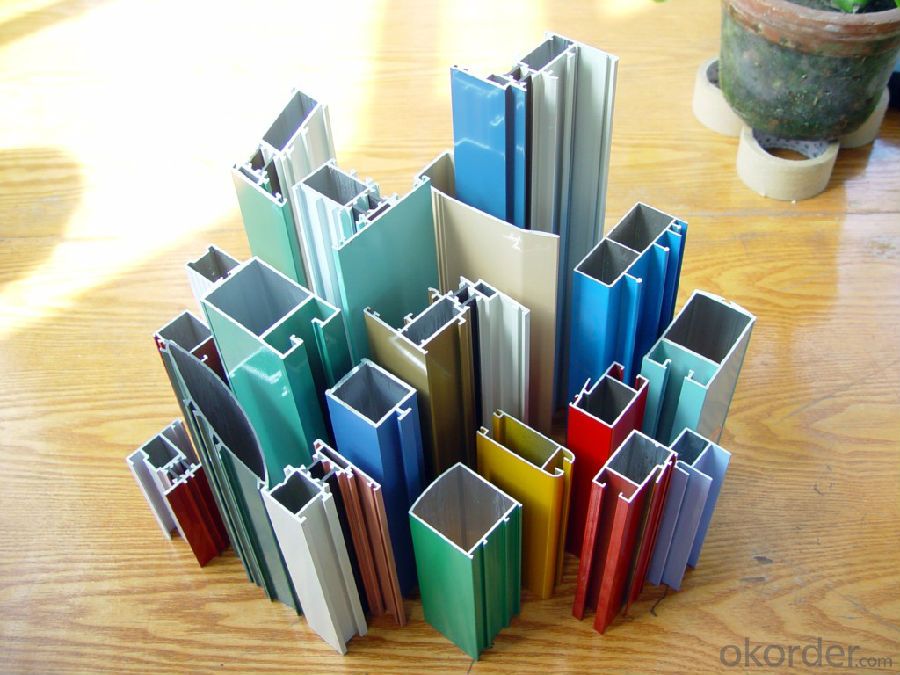

3.Aluminium Alloy Profile for Window and Door Images:

4.Aluminium Alloy Profile for Window and Door Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Are there any limitations to the minimum coil width of aluminum coils?

- Limitations exist for the minimum coil width of aluminum coils due to various factors, such as the manufacturing process and equipment used. Generally, the coil width is restricted by the capabilities of the rolling mill or other processing machinery. The minimum coil width is typically determined by the size of the rolls or mandrels utilized during production. If the coil width becomes too narrow, it can lead to stability and integrity issues, making handling and transportation more challenging. Furthermore, a narrower coil width may impact the overall efficiency of the manufacturing process. Hence, it is crucial to take these limitations into account when establishing the minimum coil width for aluminum coils.

- Q: Four roller rolling mill roller bearing on the aluminum top how always have holes, in the production process, will be printed on just above the work roll, the work roll used in less than a day, it will produce a pothole, and aluminum plate will be printed from the upper supporting roller above the straight line, the line in the above there are holes.

- Well, typical aluminum plate surface defects in the backup roll print, solution, change support roll.Do not know your factory function division, should have special polishing work roll, support roller grinding workshop, this problem should be addressed to them, sticks are not qualified, how can dry out qualified products?

- Q: Can aluminum coils be used in electrical conductors?

- Yes, aluminum coils can be used in electrical conductors. Aluminum is a good conductor of electricity and is commonly used in various electrical applications, including wiring, power transmission, and motor windings.

- Q: How do aluminum coils contribute to the sound insulation of buildings?

- Aluminum coils contribute to the sound insulation of buildings through their unique properties and applications. Aluminum is a lightweight and flexible material that can be easily formed into coils, making it an ideal choice for sound insulation purposes. One of the main ways aluminum coils contribute to sound insulation is by acting as a barrier to prevent the transmission of sound waves. When installed in walls, ceilings, or floors, these coils create an additional layer that helps to block and absorb sound energy. Aluminum has a high density and rigidity, which allows it to effectively reflect and absorb sound waves, reducing their intensity as they pass through the building structure. Moreover, aluminum coils can be combined with other soundproofing materials, such as foam or fiberglass, to enhance their sound absorption capabilities. These combinations provide a more comprehensive sound insulation system, as the different materials work together to trap and dampen sound waves. Another advantage of aluminum coils is their resistance to moisture and corrosion, which makes them suitable for both indoor and outdoor applications. This durability ensures that the sound insulation provided by aluminum coils remains effective over time, even in harsh environments. Additionally, aluminum coils are easy to install and maintain, making them a cost-effective solution for sound insulation in buildings. Their lightweight nature allows for easy transportation and handling, while their flexibility enables them to be installed in various positions and configurations. In summary, aluminum coils contribute to the sound insulation of buildings by acting as a barrier to sound transmission, reflecting and absorbing sound waves, and providing durability and versatility. Their combination with other soundproofing materials further enhances their effectiveness. With their lightweight and flexible properties, aluminum coils offer a practical and cost-effective solution to improve the acoustic performance of buildings.

- Q: Can aluminum coils be used in electrical busbars?

- Indeed, electrical busbars can utilize aluminum coils. Due to its high electrical conductivity, affordability, and lightweight nature, aluminum is widely employed as a busbar material. Aluminum coils can effortlessly be molded into different configurations and dimensions, tailored to meet specific busbar criteria. Furthermore, aluminum possesses commendable thermal conductivity, facilitating efficient dissipation of heat in applications involving high currents. Nevertheless, it is crucial to take into account the current carrying capacity, mechanical strength, and corrosion resistance of aluminum coils when opting for them in busbar applications.

- Q: I have the Samp;W Mamp;P 15 rifle and was wondering if I should oil the exterior of the rifle. The receiver material is 7075 T6 Aluminum and the finish is Hard Coat Black Anodized (specifications on website). Any advice or tips are welcome! Thanks!

- Aluminium does not rust. The anodized finish protects the aluminium from oxidization. So no, oiling the finish is not necessary.

- Q: What is the typical thermal expansion coefficient for aluminum coils?

- The typical thermal expansion coefficient for aluminum coils is around 23.1 x 10^-6 per degree Celsius (or 23.1 x 10^-6/°C). This coefficient represents the change in length of an aluminum coil per degree Celsius increase in temperature. It is important to note that this value may vary slightly depending on the specific alloy and composition of the aluminum coil.

- Q: How are aluminum coils different from other types of metal coils?

- Aluminum coils are different from other types of metal coils primarily due to their unique properties and characteristics. Unlike other metals, aluminum is lightweight, corrosion-resistant, and highly malleable, making it an ideal material for various applications such as construction, automotive, and electronics. Additionally, aluminum coils have excellent conductivity, enabling efficient heat transfer and electrical conductivity. These qualities, coupled with its affordability and recyclability, set aluminum coils apart from other metal coils in terms of versatility and practicality.

- Q: What is the fatigue strength of aluminum coils?

- Various factors, including the specific alloy used, the manufacturing process, and the application, can cause the fatigue strength of aluminum coils to vary. In comparison to other materials, aluminum alloys generally possess good fatigue strength, making them appropriate for a broad range of applications that necessitate resistance to cyclic loading and fatigue. Due to their lightweight nature and excellent corrosion resistance, aluminum coils find common use in industries such as automotive, aerospace, and electrical. Fatigue testing is typically employed to determine their fatigue strength, involving subjecting the material to repeated cycles of stress until failure occurs. Aluminum alloys in coil form are engineered to endure cyclic loading without experiencing significant damage or failure. The fatigue strength of aluminum coils can be influenced by factors like alloy composition, heat treatment, and surface finish. Generally, higher strength aluminum alloys, such as those belonging to the 7000 series, exhibit greater fatigue strength compared to lower strength alloys like the 1000 or 3000 series. To accurately ascertain the specific fatigue strength of aluminum coils, it is vital to consider the intended application, expected stress levels during operation, and desired service life. Predictions regarding fatigue life can be made using various models and testing methods, such as S-N curves (stress amplitude vs. number of cycles to failure). In summary, aluminum coils generally possess good fatigue strength, rendering them a suitable choice for applications requiring resistance to cyclic loading and fatigue. However, the specific fatigue strength of aluminum coils can vary depending on factors such as alloy composition, heat treatment, and surface finish. To accurately determine the fatigue strength for a specific application, it is advisable to consult technical specifications or conduct fatigue testing.

- Q: Is it possible to utilize a grinder to smooth out or remove a damaged area on a steel coil?

- <p>Yes, you can use a grinder to grind down a damaged section of a steel coil. However, it's crucial to use the appropriate type of grinder designed for metalworking and to ensure safety precautions are taken, such as wearing protective gear. The grinder should be capable of handling the hardness of the steel and should be operated by someone experienced with such equipment. Always follow the manufacturer's guidelines and safety standards to prevent accidents and ensure the effectiveness of the grinding process.</p>

Send your message to us

Customized Coated Aluminum Coil for Aluminium Alloy Profile for Window and Door in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords