Aluminum Coil for Channel Letter with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

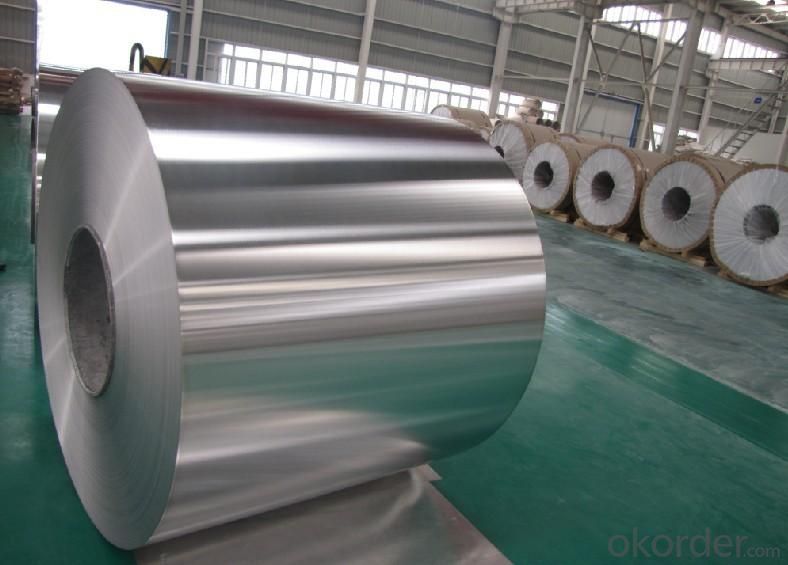

Structure of Aluminium Coil with Good Price and Excellent Quality Description:

Aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Coil with Good Price and Excellent Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium Coil with Good Price and Excellent Quality:

Aluminium Coil with Good Price and Excellent Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- There are two actions going on here. Throwing away a can and pouring out gasoline. Both are examples of wasting energy and the writer was trying to put a visual to the comparison. Since cans come in various sizes, the amount of energy is relative to the size of the can. For example, throwing out a 12 oz can is the same as pouring out 6 oz of gas.

- Q: Can aluminum coils be used in the production of consumer electronics?

- Yes, aluminum coils can be used in the production of consumer electronics. Aluminum coils are commonly used in various electronic devices, such as smartphones, laptops, and televisions, due to their lightweight, high conductivity, and thermal efficiency properties. They are used in components like heat sinks, connectors, and circuit boards to ensure efficient heat dissipation and electrical conductivity, thereby enhancing the performance and reliability of consumer electronics.

- Q: Can aluminum coil 3003H24 replace 3A21H14?

- It is ok in some way as both of them are alumal. The hardness of 3003H24 is similar to that of 3A21H14 after hardening without annealing. Both have good corrosion resistance, plasticity and bad machinability. They cannot be used as load bearing parts even though small load is ok. They cannot be anodized.

- Q: The company wants to produce an aluminum coil production line, which is better for large aluminium smelting equipment?

- Dongpu heat well, they have the qualification certificate issued by the state kiln construction, as far as I know, their melting furnace Aluminum Alloy 'plan is very good, and the operation is simple and safe, feel good, can be wiped off

- Q: How are aluminum coils joined together?

- Aluminum coils can be joined together through a process known as welding, which involves melting the edges of two metal pieces and allowing them to cool and fuse. There are multiple welding methods that can be used to join aluminum coils, such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and friction stir welding (FSW). GTAW, also referred to as TIG (tungsten inert gas) welding, is a precise and versatile method commonly employed for joining aluminum coils. It utilizes a non-consumable tungsten electrode to create an electric arc that melts the base metal. Meanwhile, an inert gas shield, usually argon, is used to protect the weld zone from contamination by the atmosphere. GMAW, or MIG (metal inert gas) welding, is another frequently used method for joining aluminum coils. It involves a consumable wire electrode that is fed through a welding gun, along with a shielding gas to prevent oxidation in the weld zone. FSW is a solid-state joining process that utilizes a rotating tool to generate frictional heat between the aluminum coils. This heat softens the metal, allowing the tool to stir and join the materials without fully melting them. These welding methods are extensively utilized in various industries, including automotive, aerospace, construction, and manufacturing, due to their ability to create strong and dependable joints between aluminum coils. Furthermore, advancements in technology have led to the development of specialized welding techniques and equipment, ensuring efficient and high-quality joining of aluminum coils.

- Q: Is aluminum silicate roll felt the same as aluminum silicate acupuncture blanket?

- No, the unit weight of aluminum silicate fiber felt is greater than that of aluminum silicate acupuncture blanket. Both are thermal insulation and fire-proof material and have the same function.

- Q: Are aluminum coils suitable for curtain wall systems?

- Curtain wall systems can greatly benefit from the use of aluminum coils. This lightweight and durable material offers a multitude of advantages. Firstly, aluminum coils possess excellent corrosion resistance, ensuring the long-lasting and sturdy nature of the curtain wall system. This makes them particularly well-suited for exterior applications, where exposure to various weather conditions is inevitable. Moreover, aluminum does not rust, setting it apart from materials like steel. In addition, aluminum coils can be easily extruded into a wide range of shapes and sizes, allowing for flexibility and creativity in the design of curtain walls. This grants architects and designers the opportunity to create visually appealing and distinctive structures. Another notable feature of aluminum is its high sustainability. It is completely recyclable, meaning that it can be reused without any loss in quality. This makes aluminum coils an environmentally friendly choice for curtain wall systems, aligning with the growing demand for sustainable building materials. Furthermore, aluminum possesses excellent thermal and electrical conductivity, which can contribute to energy efficiency in curtain wall systems. By incorporating thermal breaks and insulation, aluminum curtain walls can effectively regulate temperature and reduce energy consumption, resulting in long-term cost savings. In conclusion, aluminum coils are an outstanding option for curtain wall systems due to their resistance to corrosion, versatility, sustainability, and energy efficiency.

- Q: Today at my school I was messing with this sketch thingy, the one with 2 knobs to twist up or down to draw, my friend decided to break it and when we broke it, this silver dust called aluminum powder got on my hands, I never knew it was dangerous cause your see, we never read the manual we just found it. About 3 minutes later he pointed to my hand and I saw blood. It kinda stung.

- The aluminum powder found in an Etch-a-Sketch will not cut you, it's much too small. In fact it's so small you could only see it's edges under a high powered microscope. The cut was most likely caused by jagged glass/plastic when you broke the Etch-a-Sketch open. It's not unusual to cut yourself and not realize until someone else sees you're bleeding.

- Q: Aluminum is soft, so I have a roll coating, the material is very soft, 0.7*970, into 2100, it can be processed

- The profile: steel wire steel wire rod steel I-beam steel H steel rail profile quality profile of other profilesThe stainless steel plate, stainless steel coil, stainless steel stainless steel tube stainless steel stainless steel wire stainless steel billet stainless steel metal products and other stainless steel materials

- Q: does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

- This Site Might Help You. RE: Anti-perspirant without aluminum chloride? does anyone know any ANTI-PERSPIRANTS that don't have any harmful chemicals such as aluminum chloride? I need something that makes you not sweat but I don't want bad chemicals in it!

Send your message to us

Aluminum Coil for Channel Letter with Good Price and Excellent Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords