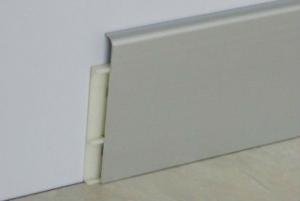

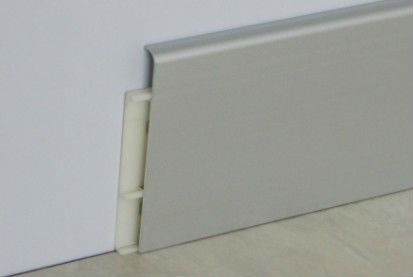

China Anodized Aluminum Frame Profiles - Aluminum Skirting Board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Aluminum skirting board 6063-T5

Main Characters

Functions: Visual balance; Decoration prettification; Protection for wall’s corners and floor.

Materials: Al 6063-T5

Hardness: 13~15 Degrees

Lifelong: 25 years over

Merits: Anti-fading; High Strength; Non-deformation; Water proof; Dump proof; Mothproof; Anti-friction; Aging resistance; Eco care; Recyclable; Easy to install;

- Q: What are the advantages of using aluminum profiles in the telecommunications infrastructure?

- Using aluminum profiles in the telecommunications infrastructure offers several advantages: 1. Lightweight: Aluminum profiles are much lighter than traditional materials like steel, making them easier to transport and install. This reduces labor costs and deployment time. 2. Resistant to corrosion: Aluminum has excellent resistance to corrosion, making it ideal for outdoor infrastructure exposed to harsh environmental conditions. It can withstand high humidity and exposure to chemicals. 3. High strength-to-weight ratio: Despite being lightweight, aluminum profiles have a high strength-to-weight ratio. This means they can support heavy equipment and structures while still being relatively light. They are perfect for applications such as antenna mounts and support structures. 4. Easy customization: Aluminum profiles can be easily customized to meet specific design requirements. They can be cut, drilled, or shaped to fit unique specifications, allowing for flexibility in design and installation. 5. Cost-effective: Aluminum profiles are generally more cost-effective compared to materials like steel or fiberglass. They require minimal maintenance, have a long lifespan, and can be recycled, reducing overall costs over the infrastructure's life cycle. 6. Electrical conductivity: Aluminum is an excellent conductor of electricity, making it suitable for telecommunications infrastructure where electrical conductivity is important. 7. Aesthetically pleasing: Aluminum profiles have a sleek and modern appearance, enhancing the overall aesthetics of the telecommunications infrastructure. This is particularly important in urban or residential areas where visual appeal is considered. Overall, the use of aluminum profiles in telecommunications infrastructure offers benefits such as lightweight design, corrosion resistance, high strength-to-weight ratio, customization options, cost-effectiveness, electrical conductivity, and aesthetic appeal. These advantages make aluminum profiles the preferred choice for various components within the telecommunications industry.

- Q: How do aluminum profiles contribute to LEED certification?

- Aluminum profiles contribute to LEED certification by being a sustainable and environmentally-friendly material. They can be easily recycled and have a low carbon footprint. Additionally, aluminum profiles are energy-efficient, as they allow for the use of natural light and reduce the need for artificial lighting. Their durability and long lifespan also contribute to reducing waste and the need for replacements, further enhancing the building's overall sustainability.

- Q: What cutting tool is better for cutting aluminum profile? Because this aluminum alloy material is used for radiator, there is 3mm thick sheet, it is standing up, and cutting to make it easy to deformation, which requires very sharp knives. After cutting for a period of time with a high speed steel tool, the tool is a little bit worn out, and the material starts to deform and the tool can no longer be used. Is it reasonable to use a corn cutter? Or it can be better solved with other tools or techniques.

- Adopt the indexable surface milling cutter for cutting, pay attention to the main deflection angle of 75 degrees or 90 degrees, the axial component is small, and the workpiece deformation is small.The blade is made of aluminum alloy slotted blade. Each has standard products.

- Q: How do aluminum profiles contribute to water management strategies?

- Due to their inherent properties and versatility, aluminum profiles play a crucial role in water management strategies. They are commonly utilized in the construction of various water management infrastructure, such as pipes, channels, and tanks. To begin with, aluminum profiles possess a combination of lightweight and sturdy characteristics that make them ideal for constructing water pipes. Their lightweight nature allows for easy transportation and installation, while their strength ensures durability and resistance to corrosion. This is particularly important in water management systems, as it minimizes the likelihood of leaks and damages, guaranteeing the efficient and effective transportation of water resources. Furthermore, aluminum profiles exhibit a high level of resistance to corrosion. As corrosion poses a significant threat in water management, as it can contaminate water and cause damage to infrastructure, the utilization of aluminum profiles significantly reduces this risk. Consequently, water quality is improved, and the lifespan of the infrastructure is prolonged. In addition, aluminum profiles offer a high degree of customization and can be fabricated into various shapes and sizes, enabling the creation of efficient water management systems. Channels, culverts, and tanks, which are essential components of water management infrastructure, can be constructed using these versatile profiles. Their flexibility allows engineers and designers to develop efficient and effective systems capable of handling large volumes of water, ensuring proper water management in different scenarios, including irrigation, flood control, and wastewater treatment. Moreover, aluminum is a sustainable material that can be recycled indefinitely without losing its properties. This makes aluminum profiles an environmentally friendly choice, aligning with sustainable water management practices. By adopting aluminum profiles, water management strategies can minimize their environmental impact and contribute to a more sustainable future. Overall, aluminum profiles exert a significant influence on water management strategies. Their lightweight yet sturdy nature, resistance to corrosion, versatility, and sustainability make them indispensable in the construction of water management infrastructure. Through the utilization of these profiles, water management systems can be built to efficiently and effectively handle water resources, reducing the risk of contamination, improving water quality, and promoting sustainability.

- Q: Ask Master: at present domestic industry deep aluminum extrusion production line of domestic manufacturers are also many, but the price is still the production line and abroad have obvious difference, then foreign production lines in what ways do better? Thank you

- The temperature of the extrusion bar and the temperature of the die and the temperature control of the outlet are more accurate. Technically speaking, after all, foreign development is much better than domestic time, from casting alloy ratio to extrusion temperature control, there is still a certain gap between time control.

- Q: What are the different surface protection methods for aluminum profiles?

- Aluminum profiles have various options for surface protection, each providing unique benefits and safeguarding against different environmental factors. Anodizing, powder coating, and liquid coating are among the most commonly used methods. Anodizing is favored for aluminum profiles due to its ability to offer exceptional corrosion resistance and improve the metal's appearance. This technique involves immersing the aluminum profile in an electrolyte solution and applying an electric current to generate an oxide layer on the surface. Anodizing can be done in different colors, allowing for personalization and visual appeal. Powder coating is another extensively employed approach for safeguarding aluminum profiles. During this process, a dry powder is electrostatically applied to the metal's surface and then cured in an oven. The powder melts and forms a durable protective layer, providing resistance against scratches, UV rays, and chemicals. Powder coating is available in a wide array of colors and finishes, offering both protection and aesthetic choices. Liquid coating, such as liquid paint or lacquer, can also be utilized to shield aluminum profiles from corrosion and other environmental elements. Liquid coatings offer versatility in terms of color and finishes, enabling customization and meeting specific design requirements. However, compared to anodizing or powder coating, liquid coatings may be less long-lasting and require more maintenance over time. Furthermore, mechanical finishing techniques like brushing or polishing can be employed to protect aluminum profiles. These methods assist in eliminating imperfections and creating a smooth and visually appealing surface. To summarize, the range of surface protection methods for aluminum profiles includes anodizing, powder coating, liquid coating, and mechanical finishing techniques. Each method presents distinct advantages in terms of corrosion resistance, durability, aesthetics, and customization options. The choice of surface protection method ultimately depends on the specific requirements, budget, and desired appearance of the aluminum profiles.

- Q: How do aluminum profiles perform in terms of corrosion resistance?

- Aluminum profiles are known for their excellent corrosion resistance. Due to the formation of a protective oxide layer on the surface, aluminum profiles are highly resistant to corrosion, even in harsh environments. This oxide layer acts as a barrier, preventing further oxidation and corrosion. Additionally, aluminum profiles can be further enhanced through various surface treatments such as anodizing or powder coating, which provide additional protection against corrosion. Overall, aluminum profiles offer exceptional corrosion resistance, making them suitable for a wide range of applications, including construction, transportation, and manufacturing industries.

- Q: Are aluminum profiles suitable for medical equipment and devices?

- Certainly, medical equipment and devices can indeed benefit from the use of aluminum profiles. Aluminum, being a versatile material, offers numerous advantages in the field of medical applications. Firstly, its lightweight nature renders it highly suitable for portable medical devices, thereby facilitating easy transportation, particularly in urgent situations. Moreover, the corrosion-resistant properties of aluminum are of utmost importance in maintaining the sterility and cleanliness of medical equipment. Furthermore, the material's durability allows it to withstand harsh environments and endure regular cleaning and sterilization procedures. Additionally, the adaptability of aluminum profiles enables effortless customization and fabrication into various shapes and sizes, thereby catering to diverse medical device designs. In conclusion, the exceptional characteristics of aluminum make it a dependable and appropriate choice for medical equipment and devices.

- Q: Can aluminum profiles be used for partitions and dividers?

- Yes, aluminum profiles can be used for partitions and dividers. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion, making it an excellent choice for such applications. Aluminum profiles can be easily fabricated and customized to create various partition and divider designs, including room dividers, office partitions, and retail space separators. They can be used in both residential and commercial settings to create functional and aesthetically pleasing spaces. The use of aluminum profiles for partitions and dividers also allows for easy installation, maintenance, and future modifications if needed.

- Q: This question asks for a list of various uses of aluminum profiles in the construction of buildings.

- <p>Aluminum profiles have versatile applications in building construction due to their strength, durability, and lightweight properties. They are used in curtain walls, window and door frames, structural glazing, and as support systems for facades. Aluminum profiles also serve as components in roofing systems, sunshades, and canopies. They are employed in the construction of balconies, handrails, and stairways for their corrosion resistance and ease of maintenance. Furthermore, aluminum profiles are utilized in the manufacturing of modular buildings and prefabricated structures, as well as in the creation of interior partitions and office cubicles. Their adaptability makes them a popular choice for both commercial and residential construction projects.</p>

Send your message to us

China Anodized Aluminum Frame Profiles - Aluminum Skirting Board 6063-T5

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords