Checkered Aluminum Sheets for Roof - AA3105 for Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

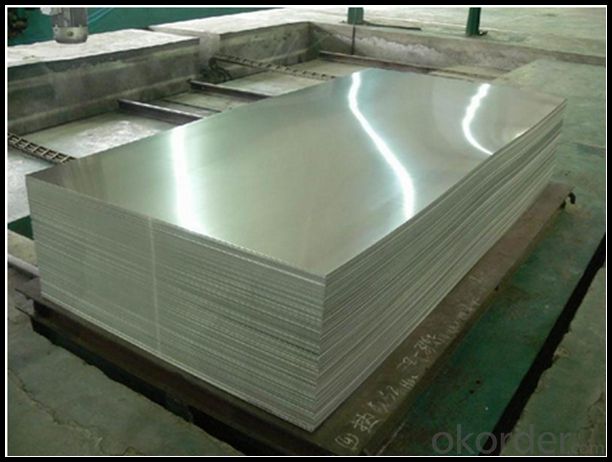

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

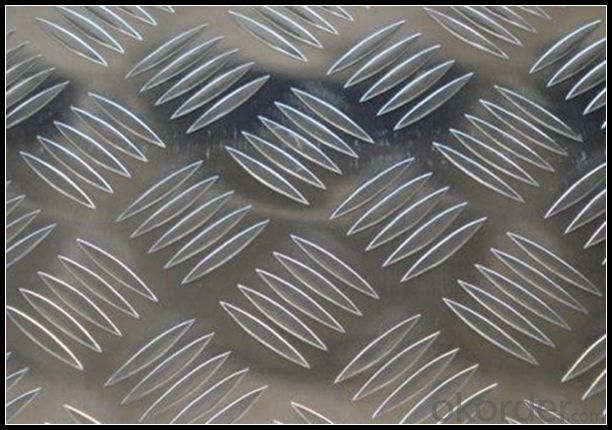

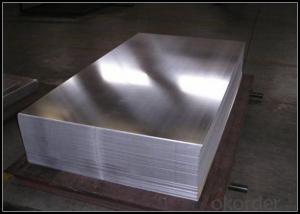

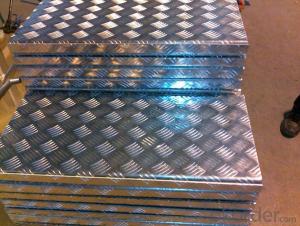

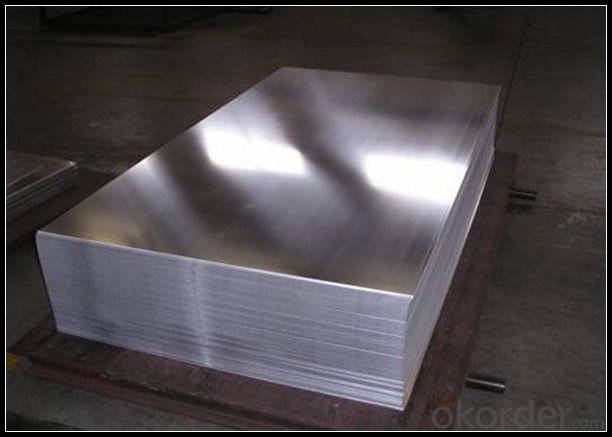

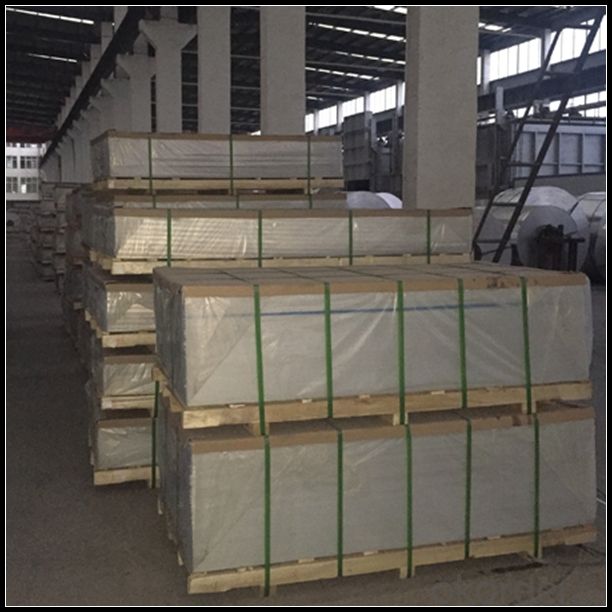

5. Image of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

6. Package and shipping of Checkered Aluminium Sheets AA3105 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Can aluminum sheet be used for heat exchangers?

- Yes, aluminum sheet can be used for heat exchangers. Aluminum is a commonly used material for heat exchangers due to its excellent thermal conductivity, light weight, and corrosion resistance. The high thermal conductivity of aluminum allows for efficient transfer of heat between fluids, making it suitable for various heat exchange applications. Additionally, aluminum is available in different alloys and thicknesses, providing flexibility in design and customization for specific heat exchanger requirements. Overall, aluminum sheet is a popular choice for heat exchangers in industries such as automotive, HVAC, and aerospace.

- Q: Can aluminum sheets be bent or formed without cracking or breaking?

- Yes, aluminum sheets can be bent or formed without cracking or breaking, as long as proper techniques such as annealing and using appropriate tooling are employed.

- Q: What is the tensile strength of aluminum sheets?

- The tensile strength of aluminum sheets can vary depending on the specific alloy and temper, but generally ranges from 20,000 to 45,000 pounds per square inch (psi).

- Q: This question asks about the various applications of aluminum sheets within the construction industry.

- <p>Aluminum sheets are versatile in construction due to their strength, durability, and lightweight properties. They are used for roofing and cladding to provide weather resistance and aesthetic appeal. Aluminum sheets are also utilized in the fabrication of window frames and doors for their strength and thermal efficiency. They are employed in the construction of scaffolding and temporary structures due to their lightweight and ease of assembly. Additionally, aluminum sheets are used in the manufacturing of facades, canopies, and decorative elements for their modern look and low maintenance requirements.</p>

- Q: What is the thickness range of aluminum sheets?

- The thickness of aluminum sheets can differ based on the particular application and industry norms. Nevertheless, usually accessible aluminum sheets generally have a thickness ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm). Thicker aluminum sheets may be obtainable for more specialized uses. It is crucial to bear in mind that diverse alloys and grades of aluminum may have varying thickness ranges. Therefore, it is essential to refer to the specific requirements and standards of the intended use.

- Q: What advantages does the ceramic panel curtain wall have compared with the aluminum sheet and stone curtain wall?

- Now, there are many kinds of ceramic curtain walls. They are made of natural clay materials. They are green, environmentally friendly, low energy consumption, and they are not easy to fade and deform. They have good corrosion resistance and durability, and high strength. At present, the domestic market of ceramic tile is faster than that of foreign countries. I heard ruigao is the first manufacturer of ceramic plate, there are other TOB ah, new Kerry ah. The strength is good.

- Q: Would a chemical reaction happen between a piece of copper and a liquid solution containing a compound of aluminum? Why or why not? FIRST BEST ANSWER GETS POINTS!

- No. Copper metal will not reduce aluminum ions to aluminum metal. We can observe that copper is below aluminum in the activity series, which indicates that the Cu + Al3+ reaction is nonspontaneous. The other way round will work, sort-of. Aluminum metal will reduce copper ions. But it takes freshly prepared aluminum metal. Aluminum metal passivates, that is, it reacts with oxygen to form an Al2O3 layer on the surface of the metal. The presence of chloride ion will help provide a clean Al surface.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Indeed, consumer goods can be manufactured using aluminum sheets. This material possesses qualities of being lightweight, durable, and easily moldable, allowing for the creation of diverse shapes and sizes. Its remarkable resistance to corrosion renders it perfect for items that may face moisture or harsh environments. Moreover, aluminum stands out as an environmentally conscious choice due to its high recyclability. The attractiveness, sturdiness, and adaptability of aluminum sheets render them an exceptional choice for producing consumer goods, including kitchen utensils, appliances, furniture, packaging materials, and automotive components.

- Q: How do I join aluminum sheets together?

- There are several methods you can use to join aluminum sheets together, depending on the specific application and desired outcome. Here are a few common techniques: 1. Riveting: Riveting involves using rivets, which are small metal fasteners, to join the aluminum sheets. This method requires drilling holes into the sheets and then inserting the rivets, which are then permanently secured by deforming or compressing them. Riveting is a durable and widely used method for joining aluminum sheets. 2. Welding: Aluminum welding can be done using various techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), or laser welding. These methods melt the aluminum at the joint, allowing it to fuse and form a strong bond when cooled. Welding requires specialized equipment and expertise, but it provides a robust and permanent joining solution. 3. Adhesive bonding: This method involves using industrial-grade adhesives specifically designed for bonding aluminum. The adhesive is applied to the surfaces to be joined, and then the sheets are pressed together and allowed to cure. Adhesive bonding offers a clean and aesthetically pleasing joint, but it may not be suitable for high-stress applications. 4. Mechanical fasteners: Using screws, bolts, or nuts is another option to join aluminum sheets. This method involves drilling holes in the sheets and using fasteners to secure them together. Mechanical fasteners provide a strong and adjustable joint, making it easier to disassemble if needed. Before selecting a joining method, consider factors such as the application's strength requirements, appearance, ease of assembly, and disassembly. Additionally, it is essential to follow safety guidelines and consider seeking professional advice if you are unsure about which method to use or lack experience with joining aluminum sheets.

- Q: Hi,I need some interesting facts about AluminiumLike who found/discovered it, and how, or/and history of it. Recycling it, or does it have effects on the environment,Thanks if you can help,Thank you thank you thank you!Xx

- Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are very important in other areas of transportation and building. Its reactive nature makes it useful as a catalyst or additive in chemical mixtures, including ammonium nitrate explosives, to enhance blast power. all the ifo u need isat the link below

Send your message to us

Checkered Aluminum Sheets for Roof - AA3105 for Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords