Custom Aluminum Sheets AA3005 for Making Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA3005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA3005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA3005 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

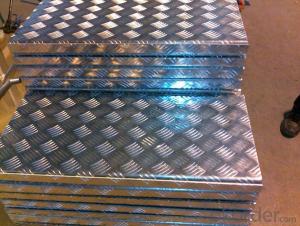

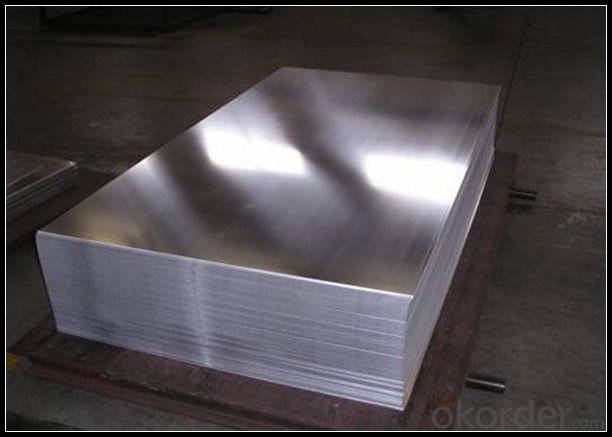

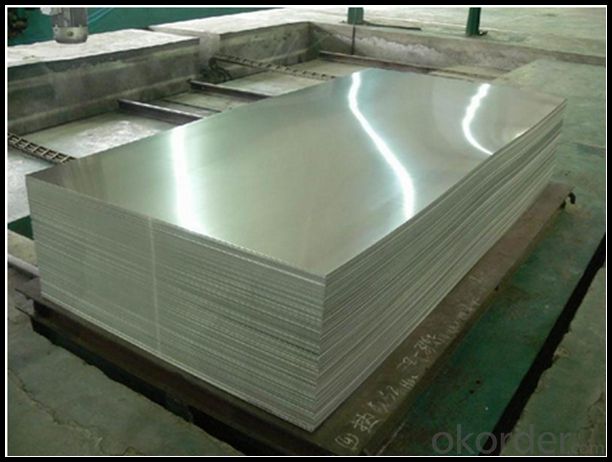

5. Image of Aluminium Sheets AA3005 for Making Aluminium Trailers

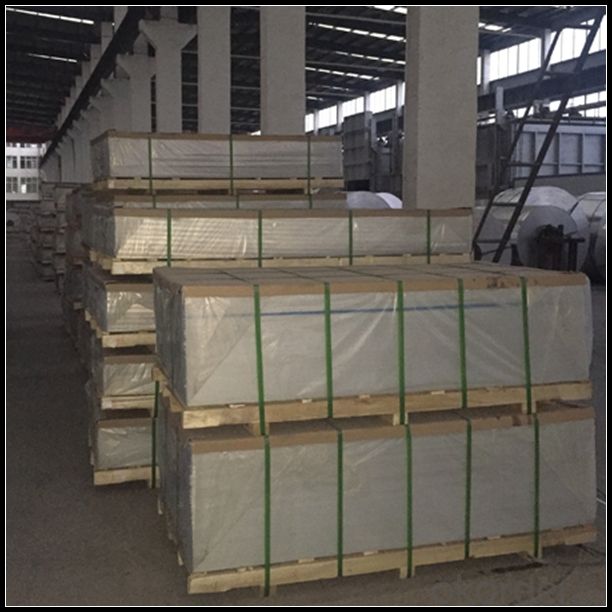

6. Package and shipping of Aluminium Sheets AA3005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are aluminum sheets suitable for use in food processing or packaging industries?

- Yes, aluminum sheets are suitable for use in food processing or packaging industries. Aluminum is a widely used material in the food industry due to its excellent properties such as being lightweight, corrosion-resistant, and having good thermal conductivity. It is also impermeable to moisture, oxygen, and light, which helps to preserve the quality and freshness of food products. Additionally, aluminum sheets can be easily formed into various shapes and sizes, making them versatile for different packaging requirements.

- Q: How is the strength and durability of aluminum sheets determined?

- The determination of the strength and durability of aluminum sheets involves the utilization of various testing methods and parameters. A key factor in establishing the strength of these sheets is their alloy composition. Different compositions of alloys possess different levels of strength, and the addition of certain elements to the aluminum can enhance its strength properties. In order to assess the strength of aluminum sheets, the commonly employed method is tensile testing. This procedure entails subjecting a sample of the sheet to tension until it fractures. Throughout the test, the load and deformation are measured, and the ultimate tensile strength (UTS) and yield strength are established. The UTS signifies the maximum amount of stress that the sheet can endure before failure, whereas the yield strength is the stress at which the material begins to deform plastically. The thickness of aluminum sheets is another crucial consideration when determining their strength and durability. Generally, thicker sheets tend to exhibit greater strength and durability compared to thinner ones due to the increased cross-sectional area that contributes to their load-bearing capacity. Apart from alloy composition and thickness, the strength and durability of aluminum sheets are also influenced by the manufacturing process. Factors such as rolling and heat treatment have the ability to alter the microstructure of the aluminum, thereby affecting its mechanical properties. Effective control of these processes is essential in order to ensure consistent strength and durability across all sheets. Moreover, the resistance to corrosion is often evaluated for aluminum sheets. Aluminum naturally forms a protective oxide layer, which enhances its resistance to corrosion. However, specific coatings or treatments can be applied to further enhance this resistance, depending on the intended application. In conclusion, the determination of the strength and durability of aluminum sheets is achieved through a combination of factors including alloy composition, thickness, manufacturing processes, and testing methods such as tensile testing. These factors collectively govern the mechanical properties and resistance of aluminum sheets to various forms of stress, rendering them suitable for a wide array of applications.

- Q: Does aluminum sheet require special handling during transportation?

- Transporting aluminum sheets requires special handling due to their lightweight nature and susceptibility to damage if mishandled. To prevent scratching, bending, or denting, it is necessary to take specific precautions. Packaging and securing the sheets in a manner that restricts movement and offers sufficient protection against impacts is crucial. Furthermore, it is important to transport aluminum sheets separately from heavy objects or materials to avoid potential damage caused by their weight. In conclusion, ensuring the safe transportation of aluminum sheets necessitates giving them special care and attention.

- Q: When zinc dust and sulfur dust are combined in certain proportional ratios and ignited, a violent exothermic reaction occurs. Because the reaction only depends on two components; zinc and sulfur, but not oxygen, the reaction has all of the components that it needs within the mixture. The same is also true for a mixture of magnesium and sulfur.However, the same reaction does not occur with iron and sulfur. Instead, the mixture reacts slowly over a period of a few minutes rather than flashing to smoke in less than a second. Now for my questions:1: If aluminum and sulfur were combined in the same proportional ratios as the zinc and the magnesium mixtures were, would the reaction be as fast as the zinc and the magnesium mixtures? Why or why not?2: What properties of the different metals used in these mixtures makes them behave so differently?

- the forged iron crucible will honestly be dragging the warmth away,so attempt to discover a ceramic crucible---you will possibly have the potential to discover them at any rings furnish domicile.you will additionally so discover commercially arranged fluxes for melting,if no longer Borax powder is a fluxing agent I generally use.With the small quantity of meral you're wishing to soften,i think of your MAPP torch ought to artwork,be confident to change the flame to a lowering flame to steer clear of gassing the metallic.the availability domicile RIOGRANDE has an entire inventory of something you are able to require besides as some preprepared alloys which you will choose to objective.

- Q: or aluminum ? and what other gases are released?

- Aluminium does not normally react with water because of a surface coating of the highly unreactive Al2O3 that forms on exposure to atmospheric oxygen. In the presence of strong base, however, this compound dissolves due to complexation by hydroxide, similarly to how silver chloride dissolves in ammonia. Al2O3(s) + 2OH-(aq) + 3H2O(l) ----- 2[Al(OH)4]-(aq) Once this has occured, aluminium metal, a very strong reducing agent, is exposed to water. 2Al(s) + 6H+(aq) ----- 2Al3+(aq) + 3H2(g) Even though the solution is alkaline, there is still a low concentration of H+ formed by the autoprotolytic dissociation of water. The Al3+ formed then reacts with hydroxide to produce more [Al(OH)4]-. Yes, the hydrogen gas is from the water.

- Q: This question asks for a comparison of the benefits and drawbacks of using aluminum sheets as a roofing material.

- <p>Aluminum sheets for roofing offer several advantages, including durability, resistance to rust and corrosion, lightweight nature, and energy efficiency due to reflective properties. They are also easy to install and maintain, and can be recycled, making them environmentally friendly. However, there are some disadvantages such as being more expensive than some other roofing materials, potential for denting if not properly installed, and noise issues during heavy rain or hail due to their lightweight nature. Additionally, they may require more frequent replacement compared to some other materials.</p>

- Q: 1. Esrp for aluminum is -1.66V. Why is Al not reactive when dipped in cold water?2. Explain why the reaction between water and Al becomes more reactive when Al has been treated first with Mercury chloride.3. Aluminum hydroxide dissolve in both acid and base. What do you call this type of behavior?4. Describe the function of aluminum hydroxide in the testile industry.5. Aluminum sol. which contains [Al(H2O)6]3+ ions have the tendency to hydrolyze. Why? Recommend a method to prevent hydrolysis of aluminum ions.6. In the preparation of alum, sulphuric acid is added to the aluminum hydroxide sol. Why?

- 1) Aluminum forms a natural oxide coating in air that is very unreactive, so when you put it from air into water, nothing happens. 2) Mercury chloride reacts with the aluminum to form an amalgam (mercury-aluminum alloy) and is very reactive. 3) Amphoteric behavior 4) No idea. Check you textbook or class notes. 5) No idea. 6) To form aluminum sulfate

- Q: The user is asking if aluminum sheets can be used as a substitute for metal siding in construction.

- <p>Yes, aluminum sheets can be used to replace metal siding. They are lightweight, durable, and resistant to corrosion, making them a popular choice for siding. Aluminum sheets can be painted or finished to match various architectural styles and are low maintenance. However, it's important to ensure that the aluminum sheets are of the appropriate gauge and quality for the application, and that they are installed correctly to ensure longevity and performance.</p>

- Q: Are the aluminum sheets suitable for HVAC (heating, ventilation, and air conditioning) applications?

- Yes, aluminum sheets are suitable for HVAC (heating, ventilation, and air conditioning) applications. Aluminum is a popular choice in the HVAC industry due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. These sheets are commonly used for ductwork, heat exchangers, and air handling units in HVAC systems. Aluminum sheets can efficiently transfer heat and withstand high temperatures, making them ideal for heating applications. Additionally, their resistance to corrosion ensures long-term durability in moist environments, such as air conditioning systems. Moreover, the lightweight nature of aluminum sheets simplifies installation and reduces the overall weight of HVAC equipment. Overall, aluminum sheets are a reliable and versatile material for HVAC applications.

- Q: Are aluminum sheets resistant to impact?

- Yes, aluminum sheets are generally resistant to impact due to their high strength-to-weight ratio and ability to absorb and distribute energy.

Send your message to us

Custom Aluminum Sheets AA3005 for Making Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords