Aluminum Sheets Flashing AA3105 for Aluminum Trailers Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA3105 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA3105 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA3105 for Making Aluminium Trailers

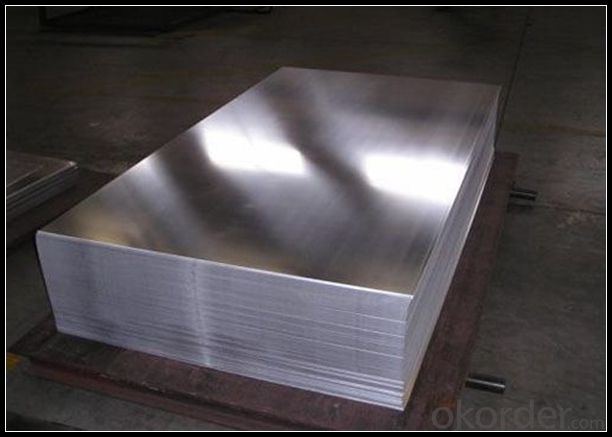

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

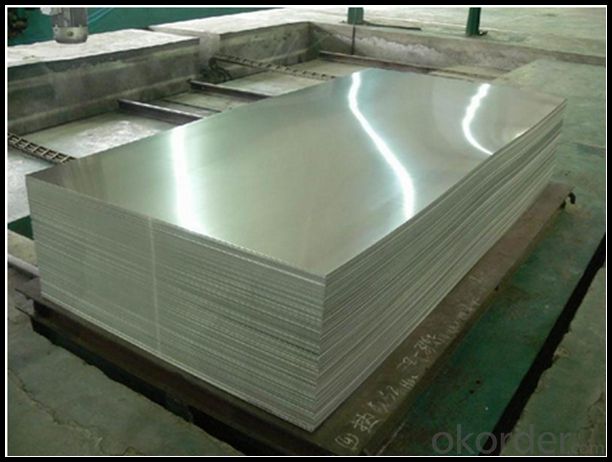

5. Image of Aluminium Sheets AA3105 for Making Aluminium Trailers

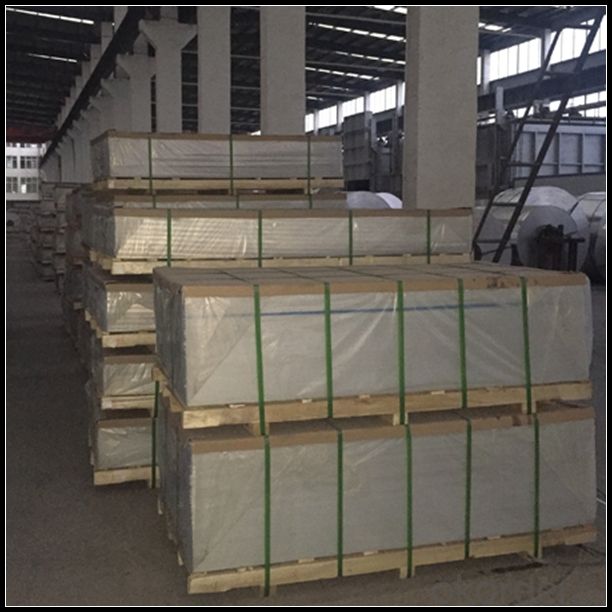

6. Package and shipping of Aluminium Sheets AA3105 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the advantages of using aluminum sheets compared to other materials?

- There are several advantages of using aluminum sheets compared to other materials. First, aluminum is lightweight, making it easier to handle and transport. Second, aluminum has corrosion resistance properties, ensuring durability and longevity. Third, aluminum sheets can be easily formed and molded into various shapes, allowing for versatility in applications. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for use in industries such as aerospace and electrical engineering. Lastly, aluminum is recyclable, making it an environmentally friendly choice.

- Q: Can 101 aluminum sheets be used in HVAC systems?

- Yes, 101 aluminum sheets can be used in HVAC systems. Aluminum is commonly used in HVAC systems due to its excellent thermal conductivity, corrosion resistance, and lightweight properties. The 101 aluminum alloy is a commonly used grade that provides good strength and ductility, making it suitable for HVAC applications. It is often used for fabricating ducts, air handlers, heat exchangers, and other components in HVAC systems. Additionally, aluminum sheets are easy to work with and can be easily formed and shaped according to the specific requirements of the HVAC system.

- Q: Can 101 aluminum sheets be used in architectural cladding?

- Yes, 101 aluminum sheets can be used in architectural cladding.

- Q: there is a magnet for other type of nails except aluminum nails

- Not that I have heard of. The best way is manual hand pick up. If it is on concrete you might try making a pad out of a good stickey tape (turning the stickey part to the outside) that might speed up the process.

- Q: im wanting to try and source my own chemicals for experiments and such in the cheapest way possiblei thought a cheap method of making powdered aluminium would be to just sandpaper aluminium kitchen foil and collect the powder, what i need to know is:how pure is aluminium foil?.....e.g is it actually mixed with some other metals and is an alloyand will the powder i collect be as good as bottled aluminium powder? i know it wont be perfect but as long as its similar that should be fineim using it for pyrotechnical experiments by the way

- Aluminum foil is pretty pure for most purposes (99.1 % pure). However, I really think sandpapering aluminum foil is not your best option. For one, aluminum foil is quite expensive, I wonder if you could just get a bunch of the powder for a cheaper price than buying an equal mass of aluminum foil. Also, how would you even begin sandpapering it? If you rub a crumpled up ball of aluminum on a rough surface, you don't get a powder, you just get a ripped up ball and a gray mark on the rough surface. But you could try, tell me if it works. However, I think you may have better odds with aluminum cans. They are cheaper and thicker thus not so prone to ripping. Although I still doubt you could get a reasonable quantity of aluminum powder from that. If all else fails, you could always try stuffing a bunch of aluminum foil in a blender.

- Q: Can the aluminum sheets be used for manufacturing heat shields?

- Yes, aluminum sheets can be used for manufacturing heat shields.

- Q: Are aluminum sheets suitable for cladding?

- Aluminum sheets are indeed appropriate for cladding purposes. The utilization of aluminum as a cladding material is widely favored due to its numerous benefits. Firstly, its lightweight nature facilitates easier handling and installation. This leads to a reduction in the overall weight of the cladding system and a minimization of structural loading. Secondly, aluminum showcases exceptional durability and resistance to corrosion, rendering it suitable for both interior and exterior applications. Additionally, it possesses weather-resistant qualities, ensuring that the cladding remains in optimal condition even in harsh climates. Furthermore, aluminum is an incredibly versatile material that can be effortlessly shaped and fabricated, thus allowing for a diverse range of design options. It may be painted or coated with various finishes to enhance its appearance and provide additional protection. Moreover, aluminum cladding necessitates minimal maintenance, as it does not require frequent cleaning or painting. In summary, aluminum sheets are an exceptional choice for cladding due to their lightweight nature, durability, versatility, and low maintenance requirements.

- Q: Can aluminum sheets be used for automotive applications?

- Indeed, aluminum sheets find their utility in automotive applications. Being both lightweight and corrosion-resistant, aluminum proves to be an optimal choice for various automotive constituents. Car bodies, engine parts, wheels, and other structural components are commonly constructed using aluminum due to its desirable properties. Aluminum sheets possess an outstanding strength-to-weight ratio, thereby enhancing fuel efficiency and overall vehicle performance. Furthermore, aluminum exhibits commendable thermal conductivity, ensuring efficient heat dissipation in automotive scenarios. Consequently, the utilization of aluminum sheets in automotive production has gained substantial popularity owing to its numerous benefits.

- Q: Why does the glue of the aluminium curtain wall glue bubble? At the same time, do not bubble on the side glass, what is the reason?

- When the air injection in silicone sealant generally refer to the site to complete the injection work, poor working conditions. The workers stood above the tripod glue injection, the uniformity of rubber injection is not easy to master, which is easy to glue in air. After sizing glue scraping the surface pressure, trimming smooth, adhesive seam inside the pad bar are mostly made of polyethylene foam obturator rods in the air inside the glue is not easy to overflow, glue dressing compressed air, will produce tension long outward, sealant seam is generally wide, small thickness, arch high displacement ability of weather resistant glue, hardness is low, no pre curing glue is very soft, compressed air pressure to hold long glue slowly bubbling. This phenomenon is more likely to occur on the application of weather resistant adhesive capable of lifting the arch + 25% or more adhesive displacement. Conversely, some weather resistant adhesives that allow less displacement are higher in hardness and thicker before the gel is solidified.

- Q: why intact aluminum sheet stop quicker than pectinate one in the magnetic field?

- while swinging in the magnetic field, intact aluminum sheets will formulate inner eddy current,that is the annular induced current.eddy current will transform the mechanical energy into heat energy, which makes the aluminum sheet stop quickly.but pectinate aluminum sheet can't formulate intact eddy current, so intact aluminum sheet stop quicker than pectinate one.

Send your message to us

Aluminum Sheets Flashing AA3105 for Aluminum Trailers Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords