Metal Aluminum Sheets AA5005 for Cabinets and Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Sheets AA5005 for Making Aluminium Trailers

ALLOY | AA1050 AA1060 AA1070 AA1100 ETC AA3003 AA3004 AA3005 AA3104 AA3105 ETC AA5005 AA5052 AA5083 AA5754 ETC AA8011 AA8006 AA8079 ETC |

TEMPER | H14,H16,H18,H22,H24,H26,H32,O/F |

THICKNESS | ≥0.2MM |

WIDTH | 30mm-2100mm |

COIL WGT | 2Mt - 3Mt |

COIL ID | φ508mm,φ610mm |

SURFACE | PE Protecting film |

STANDARD | GB/T 3880-2006 |

2. Application of Aluminium Sheets AA5005 for Making Aluminium Trailers

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Sheets AA5005 for Making Aluminium Trailers

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

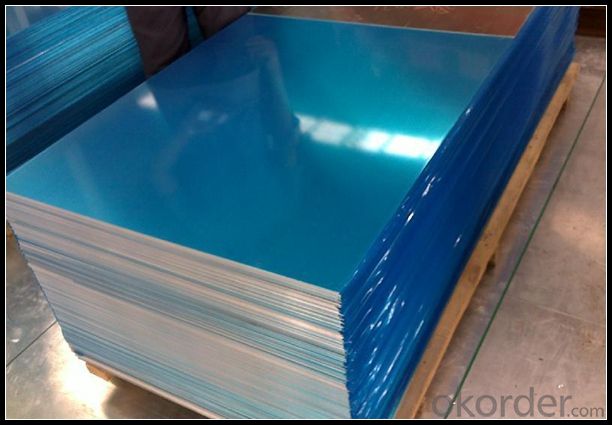

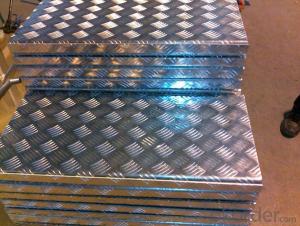

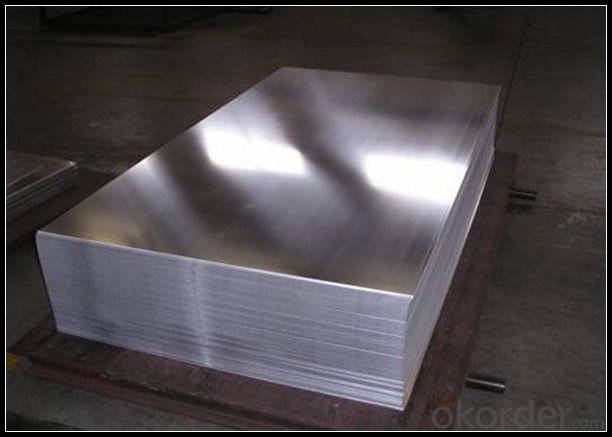

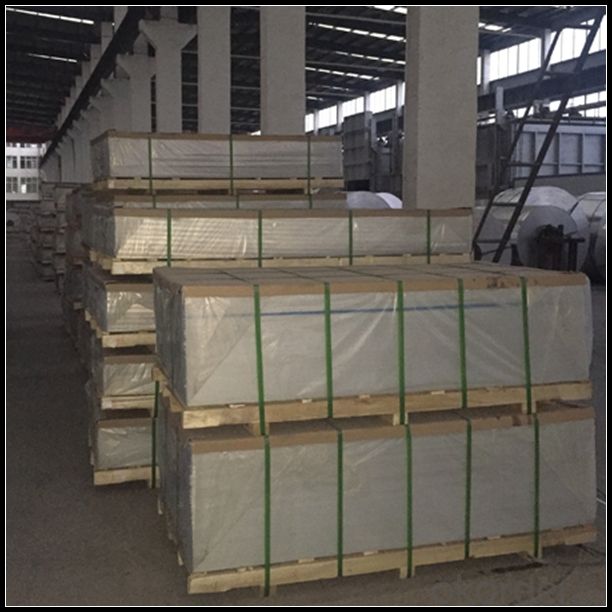

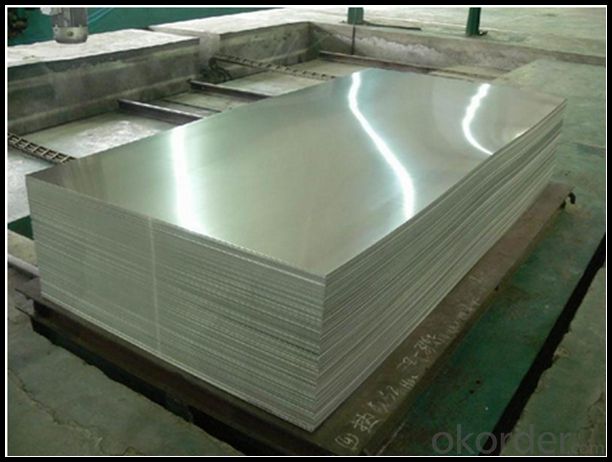

5. Image of Aluminium Sheets AA5005 for Making Aluminium Trailers

6. Package and shipping of Aluminium Sheets AA5005 for Making Aluminium Trailers

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Are the aluminum sheets suitable for manufacturing automotive fuel tanks?

- Yes, aluminum sheets are suitable for manufacturing automotive fuel tanks. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for fuel tank manufacturing.

- Q: What is the thickness of an aluminum sheet?

- The specific application and requirements determine the variability in the thickness of an aluminum sheet. A wide variety of thicknesses, usually ranging from 0.006 inches (0.15mm) to 0.25 inches (6.35mm) or even more, can be found in aluminum sheets. Gauge is the usual unit of measurement for thickness, where higher gauge numbers indicate thinner sheets. To choose the right thickness for an aluminum sheet, one must consider the intended use and desired properties like strength, flexibility, or weight.

- Q: Dear all, i'm having crack problem with bending aluminium sheet metal, anyone know than which type(Model) of aluminium sheet metal is suitable for bending, Thanks.

- THERE WERE MANY TYPES OF ALUMINUM ACCORDING TO ITS RIGIDITY. Please refer to RS Industrial catalogue for your data references.

- Q: What is the electrical resistivity of aluminum sheets?

- Aluminum sheets usually exhibit an electrical resistivity within the range of 2.65 to 2.82 micro-ohm centimeters. Nevertheless, it should be emphasized that the precise resistivity is subject to variation based on factors such as the alloy composition, thickness, temperature, and other considerations.

- Q: is there aluminum oxide on the surface of aluminum sheet after being polished by abrasive paper?

- aluminum will be oxided as aluminum oxide once being exposed in air.

- Q: Can aluminum sheets be used for roof flashing?

- Yes, aluminum sheets can be used for roof flashing. Aluminum is a popular choice for roof flashing due to its durability, corrosion resistance, and lightweight properties. It provides a reliable barrier against water penetration and helps to redirect water away from vulnerable areas on the roof, such as valleys and chimneys. Additionally, aluminum flashing is relatively easy to install and maintain, making it a practical choice for roof flashing purposes.

- Q: Can aluminum sheets be used for elevator panels?

- Yes, aluminum sheets can be used for elevator panels.

- Q: Can aluminum sheet be painted or coated after fabrication?

- Indeed, it is possible to paint or coat aluminum sheet after it has been fabricated. Aluminum, being a versatile material, lends itself easily to being painted or coated in order to improve its appearance or provide extra protection. The procedure involves preparing the surface through thorough cleaning and the elimination of any impurities, followed by the application of a primer to enhance adhesion. Once the primer has dried, a topcoat of paint or coating can be applied to achieve the desired color or finish. The choice of paint or coating will depend on the intended usage and the specific requirements of the application. All in all, painting or coating aluminum sheet after fabrication is a widespread practice that can significantly enhance its aesthetics and durability.

- Q: Are the aluminum sheets suitable for manufacturing consumer goods?

- Indeed, consumer goods can be manufactured using aluminum sheets. This material possesses qualities of being lightweight, durable, and easily moldable, allowing for the creation of diverse shapes and sizes. Its remarkable resistance to corrosion renders it perfect for items that may face moisture or harsh environments. Moreover, aluminum stands out as an environmentally conscious choice due to its high recyclability. The attractiveness, sturdiness, and adaptability of aluminum sheets render them an exceptional choice for producing consumer goods, including kitchen utensils, appliances, furniture, packaging materials, and automotive components.

- Q: Are aluminum sheets suitable for heat exchangers?

- Aluminum sheets, indeed, are well-suited for heat exchangers due to their numerous advantageous qualities. Firstly, aluminum, being a highly conductive metal, facilitates efficient heat transfer, effectively enhancing the performance of the heat exchanger. Furthermore, its lightweight composition simplifies the handling and installation process within heat exchanger systems. Moreover, aluminum exhibits remarkable resistance against corrosion, guaranteeing the heat exchanger's endurance and sturdiness. Additionally, the malleability of aluminum sheets enables effortless shaping and sizing, thus enabling customization for various heat exchanger designs. In summary, aluminum sheets provide exceptional thermal conductivity, corrosion resistance, and versatility, rendering them a fitting choice for heat exchanger applications.

Send your message to us

Metal Aluminum Sheets AA5005 for Cabinets and Aluminum Trailers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords