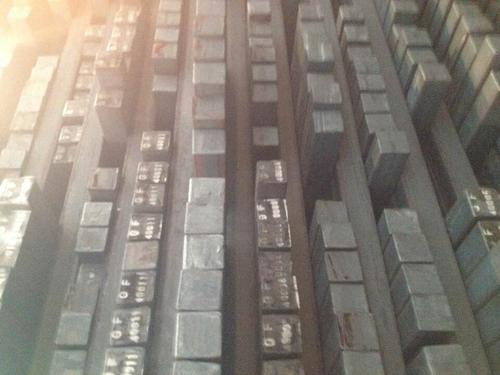

Carbon Steel Square Bar and Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Carbon Steel Square Bar and Billet at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Carbon Steel Square Bar and Billet are ideal for structural applications and are used in rolling different shape of the section steel for constrution.

Product Advantages:

OKorder's Carbon Steel Square Bar and Billet are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m,12m, as per customer request

Packaging: Export packing, nude packing, bundled

Product Name | Steel Square Bar |

Size | 60×60mm, 100×100mm, 120×120mm, 130×130mm, 150×150mm |

Length | 6M, 9M, 12M |

Grade | Q195, Q235, Q275, 3SP, 5SP, 20MnSi, Etc |

Standard | ASTM, GB, JIS |

Chemical Composition | Q235: C: 0.14-0.22% MN:0.3-0.7% SI: 0.3% max P:0.045%max S:0.045%max |

Q275 C: 0.27-0.38% MN:0.5-0.8% SI: 0.3% max P:0.045%max S:0.045%max | |

According to Customers Needs |

Trademark | Rank | Chemical composition (quality score) % | |||||

C | Si | Mn | S | P | |||

≤ | ≤ | ≤ | |||||

Q235 | A | 0.14-0.22 | 0.30 | 0.30-0.65 | 0.050 | 0.045 | |

Q235 | B | 0.12-0.20 | 0.30 | 0.30-0.70 | 0.045 | 0.045 | |

Trademark | Rank | Pulling Test | |||||

Bend PointΔs/Mpa | Tensile Strength | Elongation Ratioδ5% | |||||

Thickness (Diameter) /MM | Thickness (Diameter) /MM | ||||||

≤16 | 16-40 | ≤16 | 16-40 | ||||

≥ | ≥ | ||||||

Q235 | A | 235 | 225 | 375-500 | 26 | 25 | |

Q235 | B | 235 | 225 | 375-500 | 26 | 25 | |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The normal sizes with the normal grade can be produced within one month. The specific shipping date is dependent upon international and government factors, the delivery to international main port about 45-60days.

Images:

- Q: How do you use a steel square to find the square footage of a patio?

- To use a steel square to find the square footage of a patio, you need to follow a few steps. First, ensure that the steel square is clean and free from any debris. Next, measure one side of the patio using the long edge of the steel square. Place the steel square against the edge of the patio, aligning the long edge with the side you want to measure. Hold the square firmly in place and make sure it is flush against the edge. Once the square is properly aligned, take note of the measurement indicated on the steel square's short edge. This measurement represents the length of one side of the patio. Repeat the process for the remaining sides of the patio, measuring each side with the steel square. Take note of the measurements for each side. To find the square footage, multiply the length of one side by the length of the adjacent side. For example, if one side measures 10 feet and the adjacent side measures 12 feet, multiply 10 by 12 to get 120 square feet. If the patio has irregular shapes or curves, you can still use the steel square to measure the square footage. Break the patio into smaller sections with straight edges and measure each section individually. Then, add up all the individual measurements to get the total square footage of the patio. Remember to account for any openings or obstacles in your calculations, as you may need to subtract their square footage from the total area. Using a steel square to find the square footage of a patio ensures accuracy and precision in your measurements, helping you determine the right amount of materials needed for your project.

- Q: What are the common mistakes to avoid when using a steel square?

- Some common mistakes to avoid when using a steel square include not checking for accuracy before use, not securely holding the square against the workpiece, using the wrong side of the square for specific measurements, not properly aligning the square with the edges of the workpiece, and not ensuring the square is perpendicular or square to the workpiece.

- Q: Can a steel square be used for measuring stair angles?

- Yes, a steel square can be used for measuring stair angles. It is a versatile tool that can be used for various types of measurements and calculations, including determining the angles of staircases.

- Q: Are steel squares rust-resistant?

- Steel squares are not inherently rust-resistant. Steel is primarily composed of iron, which is prone to rusting when exposed to moisture and oxygen. However, steel squares can be made rust-resistant through a process called galvanization or by applying protective coatings such as paint or enamel. Galvanization involves coating the steel with a layer of zinc, which acts as a barrier to protect the underlying steel from rusting. These protective measures significantly enhance the rust resistance of steel squares and increase their longevity.

- Q: How do you use a steel square to determine the angle of a compound miter bevel cut?

- To determine the angle of a compound miter bevel cut using a steel square, you can follow these steps: 1. Place the steel square on the edge of the material you want to cut, with one arm of the square against the surface and the other arm extending outward. 2. Adjust the angle of the steel square until the surface arm aligns with the direction of the bevel cut you want to make. 3. Once properly aligned, read the angle measurement on the scale of the steel square where the other arm intersects. 4. This angle measurement will give you the angle of the compound miter bevel cut you need to set on your saw.

- Q: How do you use a steel square to determine the angle of a dado groove cut?

- To determine the angle of a dado groove cut using a steel square, the following steps should be followed: 1. Begin by setting up the workpiece and ensuring it is securely in place, leveled, and stable. 2. Position the steel square along the edge of the workpiece, aligning one side of the square with the wood's surface. 3. Identify the side of the steel square that contains angle markings, typically located on the longer side. 4. Locate the angle measurement that corresponds to the desired angle of the dado groove cut. For example, if a 45-degree angle is desired, find the marking indicating 45 degrees. 5. Align the identified angle marking with the edge of the workpiece. 6. Securely hold the steel square in position, ensuring it remains stable and doesn't shift during the next step. 7. Using a pencil or marking knife, trace along the edge of the steel square, marking the line where the dado groove cut will be made. This line represents the desired angle determined by the steel square. 8. Verify the alignment of the steel square and the marked line to ensure accuracy. 9. Finally, proceed to make the dado groove cut along the marked line using appropriate tools such as a dado blade on a table saw or a router with a straight bit. Remember to maintain a steady hand and adhere to all safety precautions when utilizing power tools. Always wear suitable safety gear and follow the manufacturer's instructions for the specific tools employed.

- Q: Can a steel square be used for checking right angles?

- Yes, a steel square can be used for checking right angles.

- Q: What are the common misconceptions about using a steel square?

- There are a few common misconceptions about using a steel square that can lead to confusion or incorrect assumptions. One common misconception is that a steel square is only used for right angle measurements. While it is true that a steel square is commonly used for measuring or creating right angles, it can also be used for a variety of other purposes, such as marking and measuring angles other than 90 degrees. Another misconception is that a steel square is only used by carpenters or construction workers. While it is indeed a valuable tool in these professions, anyone who works with measurements and angles can benefit from using a steel square. It can be useful for DIY projects, woodworking, metalworking, and other crafts or hobbies. Some people may also assume that using a steel square is complicated or requires advanced mathematical knowledge. However, this is not the case. With a basic understanding of its components and functions, anyone can easily learn how to use a steel square. There are plenty of online tutorials and guides available that can help beginners get started. Lastly, some individuals may think that a steel square is an outdated or obsolete tool in the age of digital measuring devices. While it is true that there are modern alternatives available, a steel square still offers several advantages. It is durable, reliable, and doesn't require batteries or calibration. Additionally, using a steel square can provide a tactile and hands-on experience that many find satisfying. In conclusion, the common misconceptions about using a steel square include its limited use only for right angles, its exclusivity to certain professions, the assumption of complexity, and the belief that it's outdated. However, understanding the versatility, accessibility, and practicality of this tool can help dispel these misconceptions and encourage more individuals to embrace its benefits in various applications.

- Q: What are some common measurements that can be taken with a steel square?

- A steel square is a versatile and essential tool used in carpentry and woodworking. It consists of a long blade and a shorter tongue, forming a right angle. Here are some common measurements that can be taken with a steel square: 1. Right angles: The primary function of a steel square is to ensure the accuracy of right angles. It can be used to check if two surfaces are perfectly perpendicular to each other, such as when constructing frames, cabinets, or bookshelves. 2. Squaring lumber: When working with rough lumber, a steel square can be used to mark and cut it into precise right angles. By aligning the blade against one edge and the tongue against another, the square can provide a guide for making accurate cuts. 3. Determining plumb: A steel square can help determine if an object is perfectly vertical or plumb. By placing the square against a surface and checking for gaps between the blade and the object, one can ensure that it is aligned properly. 4. Measuring angles: Although primarily used for right angles, a steel square can also be used to measure other angles. By aligning the blade or tongue against the desired angle, one can transfer or replicate the angle accurately. 5. Marking parallel lines: A steel square can be used to mark parallel lines by sliding it along the edge of a board while marking the desired distance at various points. This ensures that the lines are equidistant and parallel to each other. 6. Setting bevels: A steel square can be used to set bevel angles on tools such as saws or planes. By adjusting the blade or tongue to the desired angle, it can serve as a guide for achieving consistent and accurate bevel cuts. 7. Checking for flatness: A steel square can be used to check the flatness of a surface. By placing the square against the surface and checking for gaps or irregularities, one can ensure that the surface is even and level. In summary, a steel square is a versatile tool that can be used for various measurements and alignments in carpentry and woodworking. Its primary functions include checking right angles, squaring lumber, determining plumb, measuring angles, marking parallel lines, setting bevels, and checking for flatness.

- Q: What are some common uses of a steel square in construction?

- Some common uses of a steel square in construction include measuring and marking right angles, checking the accuracy of cuts and joints, laying out stairs, rafters, and roofs, and as a guide for making straight cuts with a circular saw.

Send your message to us

Carbon Steel Square Bar and Billet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords