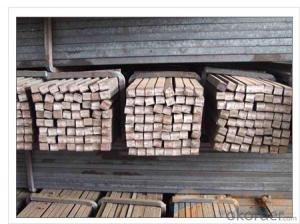

square steel carbon steel square bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

We offer Square Steel Bar with grade Q195 / Q235

Specifications of Square Steel Bar:

-Standard: GB,

-Grade: Q195/Q235 or equivalent.

Chemical Composition:

-Chemical Composition. Q195

Standard | Grade | Element (%) | ||||

GB | Q195 | C | Mn | S | P | Si |

0.06~0.12 | 0.25~0.50 | ≤0.050 | ≤0.045 | ≤0.30 | ||

-Chemical Composition. Q235

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures and Tolerances of Square Steel Bar:

(The section of Square Steel Bar)

-The length of a side and the theoretical weight of Square Steel.

Length of a side(a, mm) | Theoretical weight(kg/m) | Length of a side(a, mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with *mean that they are not regulars or we don’t offer them.

-The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Usage/Applications of Steel Square Bar:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Packaging & Delivery of Steel Square Bar:

-Packing Detail: The products can be packed in bundles by steel wires.

-Marks:

1, Tag marks: the tag marks will be tied up to each bundle of the products. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications, the painted color and other information requested by customers.

2, Color marks: we will paint both ends of the bundles of these products to make sure that they are more evident. It’s will be more convenient for the customers to distinguish them at the destination port.

-Delivery Detail: 30~45 working days after receive buyer’s T.T. or L/C.

Transportation:

-The products can be delivered by bulk vessel or by container. As for container, products with the length of 6m will be loaded in 20’ container, with 9m or 12m, in 40’ container.

-The maximum quantity of loading of container is 25 tons.

-The products usually are transported to the nearest port from the production place.

Payment:

-Invoicing on theoretical weight or actual weight a s customer’s request.

-FOB, CFR or CIF.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

- Q: Can a steel square be used for measuring roof pitches?

- Yes, a steel square can be used for measuring roof pitches. The markings and angles on a steel square make it a useful tool for determining the pitch or slope of a roof.

- Q: How do you use a steel square to lay out a dovetail joint?

- In order to lay out a dovetail joint using a steel square, you will require the following tools: a steel square, a pencil or marking knife, and either a dovetail template or a set of dovetail angle guides. Begin by ensuring that your steel square is clean and free from any dirt or debris that may impact your measurements. Then, position the steel square against the edge of the workpiece that will form one side of the dovetail joint. Make sure that the inside edge of the square's blade aligns precisely with the edge of the workpiece. Next, employ a pencil or marking knife to mark the desired width of the dovetail pins or tails on the end grain of the workpiece. The width can be determined based on the size of your stock and personal preference. Generally, a 1:8 or 1:6 angle is utilized for dovetail joints, although this may vary based on the project. Once the width has been marked, utilize the steel square to mark the desired angle of the dovetail joint on the face of the workpiece. Place the blade of the square against the face of the workpiece, aligning it with the mark made for the width of the dovetail, and draw a line along the blade to indicate the angle. Repeat these steps for the other side of the dovetail joint, ensuring accurate and consistent positioning of the steel square. This will guarantee proper alignment and a seamless fit between both sides of the joint. If you possess a dovetail template or angle guides, they can be employed to guide the steel square and simplify the process. Simply position the template or angle guide against the edge of the workpiece and use the steel square to mark the width and angle accordingly. Always remember to double-check your measurements and marks prior to cutting the dovetail joint. Accuracy is of utmost importance for a tight and sturdy joint.

- Q: Can a steel square be used for checking the squareness of a table?

- Yes, a steel square can be used for checking the squareness of a table.

- Q: Can a steel square be used for crown molding installation?

- Yes, a steel square can be used for crown molding installation. A steel square is a versatile and accurate tool that can be used for various carpentry tasks, including crown molding installation. It can be used to mark and measure angles, ensuring precise cuts and a proper fit for crown molding pieces. However, it is important to note that using a steel square for crown molding installation may require some additional calculations and adjustments due to the complex nature of crown molding angles. It is advisable to consult a professional or refer to a comprehensive guide for accurate measurements and cutting techniques specific to crown molding installation.

- Q: How do you use a steel square for creating precise corner spline joints?

- To use a steel square for creating precise corner spline joints, you would first measure and mark the desired location for the joint on the wood. Next, place the steel square on the marked corner and align it with the adjacent edges of the wood. Use a pencil or a knife to trace along the edge of the square, creating a precise guideline for the joint. Repeat this process on the other piece of wood that will be joined. This guideline will help you accurately cut and align the splines, ensuring a precise and snug fit for the joint.

- Q: How do you use a steel square for marking roof dormer angles?

- To use a steel square for marking roof dormer angles, you will need to follow a few steps. 1. Begin by positioning the steel square on the edge of the roof where the dormer will be located. Make sure the square is aligned with the roof's pitch or slope by placing the longer arm of the square against the roof. 2. Align the shorter arm of the square with the desired angle for the dormer. This angle will depend on the design and specifications of the dormer you are constructing. 3. Once the square is properly aligned, use a pencil or marker to trace along the edge of the shorter arm of the square. This will create a straight line on the roof, indicating the angle at which the dormer will be constructed. 4. Repeat this process for each side of the dormer, ensuring consistency in the angles and measurements. 5. After marking all the necessary angles, you can use these lines as guides for cutting and constructing the dormer. Make sure to double-check your measurements and angles before proceeding with the construction process. Using a steel square for marking roof dormer angles provides accurate and precise measurements, helping you create a dormer that fits seamlessly into the existing roof structure. It is essential to follow safety guidelines and use proper tools when working on any roofing project.

- Q: Can a steel square be used for checking the flatness of a countertop?

- A steel square, by no means, is intended or appropriate for verifying the evenness of a countertop. Its main function lies in measuring angles and ensuring perpendicularity, rather than determining the flatness of a surface. For the purpose of examining the evenness of a countertop, it is advisable to utilize a straightedge or a level, as these instruments are explicitly designed for this task.

- Q: Can a steel square be used for checking the alignment of door frames?

- Checking the alignment of door frames can be done using a steel square. A steel square, which is also referred to as a combination square, is a tool with a ruler and an adjustable square head. It is commonly utilized in woodworking and carpentry to measure, mark, and examine angles. To check the alignment of a door frame with a steel square, the first step is to ensure that the square is set at a 90-degree angle. Afterward, the square should be placed against the inner edge of the door frame, ensuring that it is flush with both the top and side of the frame. By visually inspecting the alignment of the square with the frame, it is possible to determine if the frame is perfectly square or if any adjustments are required. Additionally, a steel square can also be employed to check the hinge side of the door frame. By placing the square against the inner edge of the frame and extending it along the frame's length, it is possible to ascertain if it is straight and free from warping. This is crucial for the proper installation and smooth operation of the door. In conclusion, a steel square is a valuable tool for checking the alignment of door frames. Its versatility and precision make it a dependable choice for carpenters, contractors, and homeowners alike.

- Q: How do you use a steel square to find the length of a board?

- To use a steel square to find the length of a board, follow these steps: 1. Begin by placing the steel square against one end of the board, ensuring that it is aligned properly with the edge. 2. Hold the steel square firmly in place, making sure it doesn't move during the measurements. 3. Look at the long side of the steel square, which is often referred to as the blade. It will have measurements marked on it. 4. Locate the inch markings on the blade and find the line that corresponds to the width of the board. For example, if the board is 6 inches wide, find the line labeled "6". 5. Once you have found the correct line, look at the short side of the steel square, called the tongue. It will have measurements marked on it as well. 6. Align the tongue with the edge of the board, ensuring that it is flush against the side. 7. While keeping the steel square and tongue in place against the board, extend the blade along the length of the board. 8. Now, observe the measurement marked on the blade where it aligns with the opposite end of the board. This measurement indicates the length of the board. 9. Take note of the measurement or use a pencil to mark it on the board for future reference. By using a steel square in this manner, you can accurately determine the length of a board, providing you with the necessary information for your woodworking or construction project.

- Q: Can a steel square be used for woodworking joinery?

- Yes, a steel square can certainly be used for woodworking joinery. While traditional woodworking squares are typically made of wood or plastic, a steel square can offer certain advantages. Steel squares are known for their durability and accuracy, making them a reliable tool for accurate measurements and ensuring precise joinery. They have a sturdy construction that maintains its shape over time, ensuring consistent and reliable results. When using a steel square for woodworking joinery, it is important to ensure that the square is properly calibrated and aligned before making any measurements or markings. This can be done by checking it against a known accurate reference or by using a combination square to verify its accuracy. Some woodworkers prefer using a steel square for joinery work because of its resistance to warping or damage that may occur with wooden or plastic squares. The steel square can withstand the pressure and rigors of woodworking tasks, making it a long-lasting and reliable tool in the workshop. However, it is worth noting that steel squares tend to be heavier than their wooden or plastic counterparts, which may affect their ease of use for some woodworkers. Additionally, steel squares may have sharp edges, so caution should be exercised when handling them to avoid injury or damaging the wood. In conclusion, while a steel square may not be the traditional choice for woodworking joinery, it can certainly be used effectively and accurately. Its durability, accuracy, and resistance to warping make it a suitable tool for woodworkers looking for a reliable and long-lasting square.

Send your message to us

square steel carbon steel square bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords