Carbon Steel S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

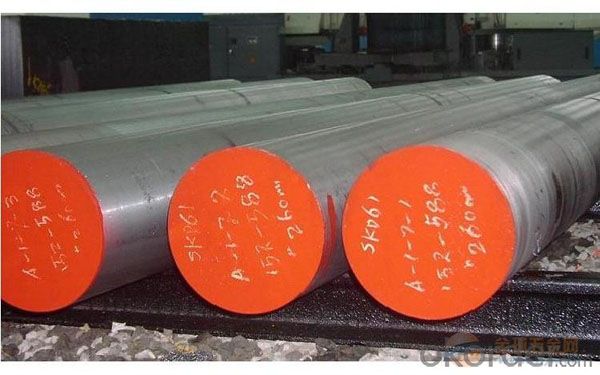

Carbon Steel S20C-B/S45C-B Steel Round Bar

Product Information:

S20C-B/S45C-B steel round bar

Dia 18-60mm

Grade 20,45#

Standard GB,JIS,ASTM,DIN,AISI,BS

LF & VD forge;ISO&TUV approved

S20C-B/S45C-B steel round bar

Round bar steel diameter 18-60mm,material 20#,45#,55#,40CrUP,40CrUC,40Mn2,20CrMnTi,42CrMo

Rolling tube blank diameter 50-130mm.material 20#,45#,10#,35#,37Mn5,Q345,20Mn2/30Mn2,45Mn2,27SiMn

Casting round tube blank diameter160-230mm,material 20#,45#,25Mn,Q345B,20Mn2/30Mn2,45Mn2,27SiMn,33Mn2V/36Mn2V,

Bearing steel diameter18-60mm,material GCr15,Flat spring steel material 60Si2Mn,55CrMnA,50CrVA

Product Overviews:

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 | GB/SAE/JIS/DIN |

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

| Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Product Show:

Our Advantages:

· Industry experience over 20 years.

· Shipment of goods -More than 70 countries worldwide.

· The most convenient transport and prompt delivery.

· Competitive price with best service.

· High technical production line with top quality products.

· High reputation based on best quality products.

With our experienced, enthusiastic and dynamic staffs, we assure to bring you the products with best quality, reasonable prices and good after-sales services under the motto: Friends First, Business After.

Communication, Experience, Expertise and Best efforts are our Promises to you.

- Q: How does special steel contribute to reducing product costs while maintaining quality?

- Special steel contributes to reducing product costs while maintaining quality through several ways. Firstly, special steel is known for its excellent strength and durability, which allows manufacturers to design products with thinner and lighter components. This reduction in material usage directly leads to cost savings without compromising on quality. Additionally, special steel possesses unique properties such as corrosion resistance, heat resistance, and wear resistance. By using special steel, manufacturers can create products that have a longer lifespan and require less maintenance or replacement. This not only reduces the overall cost of ownership for customers but also enhances the reputation of the brand for delivering reliable and high-quality products. Furthermore, special steel often allows for improved manufacturing processes, such as easier machinability or better weldability, which can result in increased efficiency and reduced production time. These time and cost savings can be passed on to the customers, making the final product more affordable without sacrificing quality. In summary, special steel's strength, durability, unique properties, and improved manufacturing processes contribute to cost reduction while maintaining or even enhancing product quality.

- Q: How does special steel perform under high-temperature conditions?

- Special steel is designed to perform exceptionally well under high-temperature conditions. It demonstrates excellent strength, toughness, and resistance to oxidation and corrosion at elevated temperatures. Additionally, special steel maintains its mechanical properties and dimensional stability even when exposed to extreme heat. Its unique composition and manufacturing techniques allow it to withstand high temperatures without significant degradation, making it ideal for applications in industries such as aerospace, power generation, and automotive.

- Q: What are the different types of free-cutting steel?

- The different types of free-cutting steel include leaded free-cutting steel, sulfurized free-cutting steel, and resulfurized and rephosphorized free-cutting steel.

- Q: Can special steel be used in the textile industry?

- Yes, special steel can be used in the textile industry. Special steel, such as stainless steel, can be utilized in various textile machinery components like needles, pins, and cutting tools due to its durability, corrosion resistance, and high strength. Additionally, special steel wire can be used in weaving, knitting, and braiding processes to enhance the strength and performance of textile products.

- Q: How does special steel perform in marine environments?

- Special steel performs exceptionally well in marine environments due to its high corrosion resistance. It is specifically designed to withstand the harsh conditions of saltwater, preventing corrosion and ensuring long-term durability. Additionally, special steel has excellent strength and toughness properties, making it suitable for various marine applications, such as shipbuilding, offshore structures, and underwater equipment.

- Q: How is special steel used in the production of automotive springs?

- Special steel is used in the production of automotive springs due to its unique properties that make it ideal for this application. Automotive springs, such as suspension springs and valve springs, need to be able to withstand heavy loads, repetitive stress, and high temperatures. Special steel, also known as alloy steel, is specifically designed to have enhanced mechanical properties compared to regular steel. It is typically made by adding additional alloying elements such as chromium, nickel, or molybdenum to improve its strength, hardness, and resistance to wear and fatigue. In the production of automotive springs, special steel is used to create springs that can handle the demanding conditions of the vehicle's suspension system. These springs must be able to absorb and distribute the weight of the vehicle, while also providing a smooth and comfortable ride. The high strength of special steel allows automotive springs to withstand heavy loads without deforming or breaking. This is crucial to ensure the stability and safety of the vehicle, especially during rough road conditions or when carrying heavy loads. Moreover, special steel's resistance to fatigue is essential in the production of automotive springs. These springs undergo millions of cycles of compression and expansion during the vehicle's lifetime. The fatigue resistance of special steel ensures that the springs can maintain their performance and reliability over an extended period. Additionally, special steel's resistance to wear and corrosion is beneficial in automotive applications. Springs are exposed to various environmental elements, such as moisture, dirt, and chemicals, which can lead to corrosion and degradation. Special steel's corrosion resistance helps to prolong the lifespan of automotive springs and maintain their functionality. In summary, the use of special steel in the production of automotive springs ensures that these critical components can withstand heavy loads, repetitive stress, and high temperatures. Its enhanced mechanical properties, including strength, fatigue resistance, and corrosion resistance, make it an ideal material choice for automotive springs, contributing to the overall performance and durability of vehicles.

- Q: What are the emerging trends in special steel production?

- Some of the emerging trends in special steel production include the use of advanced technologies, such as additive manufacturing and automation, to enhance efficiency and precision in the production process. Additionally, there is a growing demand for eco-friendly and sustainable production methods, leading to the development of greener steelmaking processes. Furthermore, there is a focus on creating specialty steels with improved properties, such as higher strength, corrosion resistance, and heat resistance, to meet the evolving needs of various industries.

- Q: What are the different methods of surface laser cladding for special steel?

- Special steel can undergo surface laser cladding using various methods. Powder-based laser cladding is one such method, involving the injection of powder material into the laser beam. This material then melts and fuses with the special steel surface, offering desired properties like enhanced hardness or corrosion resistance. With this method, precise control over the cladding layer's thickness and composition is achievable. Wire-based laser cladding is another method. Here, a wire material is fed into the laser beam, which then melts and fuses with the special steel surface. Wire-based laser cladding is predominantly used for larger areas or when a thicker cladding layer is needed. It is also commonly employed to repair or salvage worn or damaged parts. A third technique is direct energy deposition (DED) laser cladding. This method utilizes a laser beam to melt a powder or wire material while depositing it onto the special steel surface. DED laser cladding facilitates the rapid buildup of multiple layers and is often utilized in additive manufacturing or for repairing high-value components. The choice of method for surface laser cladding depends on various factors, including the desired cladding thickness, material properties, and specific application requirements. Each method has its own advantages and limitations.

- Q: Can special steel be used in the production of musical instruments?

- Yes, special steel can be used in the production of musical instruments. Special steel, also known as tool steel or high-performance steel, is a type of steel that has been specifically designed to possess certain properties that make it suitable for specific applications. These properties include high strength, durability, and resistance to wear and corrosion. In the case of musical instruments, special steel can be used in various components, such as strings, springs, keys, valves, and reeds. For example, piano strings are typically made from high-carbon steel, which provides the necessary strength and elasticity for producing the desired sound. Brass instruments like trumpets or saxophones have valves made from special steel alloys that have excellent corrosion resistance and can withstand the repetitive movements required for playing the instrument. In addition, special steel can also be used in the manufacturing of instrument parts like guitar frets. Frets are metal strips embedded along the fingerboard of a guitar, and they need to be made from a material that is durable, wear-resistant, and able to hold its shape over time. Special steel alloys, such as stainless steel or nickel-silver, are commonly used for this purpose. Overall, special steel offers a range of properties that can enhance the performance and longevity of musical instruments. By using this type of steel, manufacturers can create instruments that produce high-quality sound, are more resistant to wear and tear, and have a longer lifespan.

- Q: How does special steel contribute to the automotive industry?

- Special steel plays a crucial role in the automotive industry by providing high-strength and durable materials for various components like engine parts, chassis, and suspension systems. These steels offer superior mechanical properties, such as increased tensile strength, toughness, and wear resistance, enabling the production of lighter, safer, and more fuel-efficient vehicles. The use of special steel also enhances the performance and longevity of automotive parts, ensuring better reliability and reduced maintenance costs for the end-users.

Send your message to us

Carbon Steel S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords