S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications

1. 2080

1. cold work mould/die steel

2. High carbon high chromium type ledeburite

3. High hardness wear resistance

Product description

1. Cr12 steel is a widely used cold work die steel, a type of high carbon high chromium ledeburite . The steel has good hardenability and good abrasion resistance

2. Mainly used to with stand the impact load is smaller, and require high abrasion resistance Die and punch, cold-cut scissors, drill sets, gauges, drawing die, pressure die thread rolling board, drawing die thread rolling die.

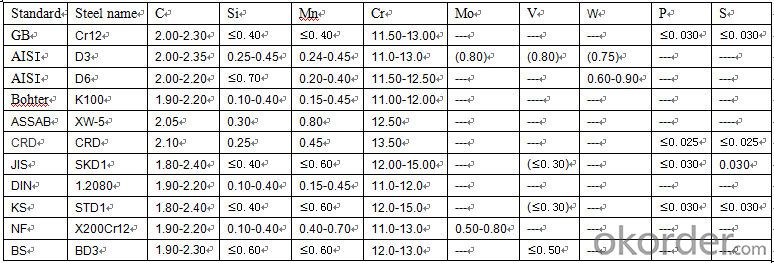

Chemical composition(for reference only)

Delivery of hardness and quenching hardness

Steel name | Delivery status | Quenched specimens | |||

Hardness HBW | Impressiondiameter (mm) | Quenching temperature/°C | Cooling medium | hardness ≥HRC | |

Cr12 | 269~217 | 3.7~4.1 | 950~1000 | oil | 60 |

Physical properties

Cr12 critical temperature

Critical point | Ac1 | Acm | Ar1 | Arcm | Ms |

temperature(approximation)/°C | 810 | 835 | 755 | 770 | 180 |

Cr12 Hot Working Technology

Item | Heating temperature/°C | start forging temperature/°C | final forging temperature/°C | type of cooling |

Steel ingot | 1140~1160 | 1100~1120 | 900~920 | Slow cooling |

Steel billet | 1120~1140 | 1080~1100 | 880~920 | Slow cooling |

Cr12 heat treatment

between the quenching temperature and the hardness of the relationship

quenching temperature/°C | 875 | 900 | 925 | 950 | 975 | 1000 | 1050 | 1100 |

Hardness HRC | 54.5 | 57 | 60 | 62.5 | 65 | 66 | 64 | 59.5 |

Delivery status: steel delivered in the annealed condition

We are professional manufacture of tool steel. We can provide various kinds of tool steel and mould steel. If you have any question regarding our products ,please feel free to let us know. We assure you will receive our best attention to your enquiry.

Products

- Q: Are steel round bars suitable for electrical conductivity?

- No, steel round bars are not suitable for electrical conductivity.

- Q: Can steel round bars be used for making propeller shafts?

- Yes, steel round bars can be used for making propeller shafts. Steel is a commonly used material for propeller shafts due to its strength, durability, and resistance to corrosion. Round bars, in particular, are often chosen for their shape, which provides optimal strength and load-bearing capabilities. The selection of steel grade and specific properties will depend on the requirements of the propeller shaft, such as the desired length, diameter, and torque capacity. Additionally, other factors like cost, weight, and manufacturability may also influence the choice of steel round bars for propeller shafts.

- Q: How do you measure the diameter tolerance of a steel round bar?

- To measure the diameter tolerance of a steel round bar, you can follow the steps below: 1. Obtain a caliper or micrometer: These measuring tools are commonly used to measure the diameter of objects accurately. 2. Set the measuring tool: If you are using a caliper, adjust the jaws to the appropriate size range. For a micrometer, ensure it is zeroed correctly. 3. Position the round bar: Place the steel round bar on a flat and stable surface, ensuring that it is not rolling or moving. 4. Take the measurement: Use the measuring tool to capture the diameter of the round bar. For accurate results, make sure the tool is perpendicular to the bar and apply gentle pressure to get an accurate reading. 5. Repeat the measurement: To ensure accuracy, take multiple measurements at different points along the length of the round bar. This will account for any variations or deviations in the bar's diameter. 6. Calculate the average diameter: Add up all the measurements and divide by the number of measurements taken. This will give you the average diameter of the round bar. 7. Compare with the tolerance range: Consult the specifications or standards provided for the steel round bar to determine the allowable tolerance range. This range will indicate the acceptable variation in diameter for the bar. 8. Analyze the results: Compare the average diameter obtained from your measurements with the specified tolerance range. If the average diameter falls within the tolerance range, the round bar meets the required specifications. However, if it falls outside the range, the bar may not meet the required tolerance and might need further inspection or adjustment. By following these steps, you can effectively measure the diameter tolerance of a steel round bar and ensure it meets the necessary specifications for your intended application.

- Q: What is the difference between a solid round bar and a hollow round bar?

- The main difference between a solid round bar and a hollow round bar is their construction. A solid round bar is uniform in shape and made of one solid piece of material, whereas a hollow round bar has a hollow center, which means it has a cylindrical shape with an empty space in the middle. This difference in construction affects their weight, strength, and application. Solid round bars are generally more robust and heavier, making them suitable for applications that require high strength and durability. On the other hand, hollow round bars are lighter in weight and often used in applications where weight reduction is crucial, such as in construction, manufacturing, and engineering industries.

- Q: Are steel round bars susceptible to corrosion?

- Steel round bars are generally susceptible to corrosion, especially when they are exposed to moisture, oxygen, and certain chemicals. Corrosion occurs when a metal reacts with its environment, leading to the degradation of the material. Steel, being an alloy primarily made of iron, can undergo various types of corrosion, such as general corrosion, pitting corrosion, and stress corrosion cracking. In the presence of oxygen and moisture, steel round bars can undergo general corrosion, which is the gradual deterioration of the material by forming an oxide layer on its surface. This can result in the loss of material and a decrease in strength over time. Pitting corrosion is another type of corrosion that steel round bars may experience. It occurs when localized areas on the surface of the metal become damaged, leading to the formation of small pits. These pits can deepen and expand, leading to structural issues and reduced integrity. Stress corrosion cracking is a specific type of corrosion that can affect steel round bars under tensile stress and in the presence of specific corrosive agents. This phenomenon can lead to the sudden failure of the material, even at stress levels below its yield strength. To mitigate the susceptibility to corrosion, steel round bars are often coated with protective layers or treated with corrosion inhibitors. Common methods include galvanization, where a layer of zinc is applied to the surface, or the use of coatings such as epoxy or paint. Additionally, regular maintenance and proper storage can help prevent excessive exposure to corrosive elements. It is important to note that the susceptibility to corrosion can vary depending on the specific grade and composition of the steel used in the round bars. Certain types of stainless steel, for example, are more resistant to corrosion due to the presence of chromium and other alloying elements. Overall, while steel round bars are susceptible to corrosion, appropriate preventive measures can be taken to minimize the risk and extend their lifespan.

- Q: How do steel round bars compare to rubber round bars?

- Steel round bars and rubber round bars are distinct materials with contrasting properties and applications. Steel round bars, which are crafted from hardened carbon steel, are renowned for their robustness and resilience. With their high tensile strength, they can endure substantial loads and stress without distorting or fracturing. Construction, engineering, and manufacturing industries frequently employ steel round bars for structural support, reinforcement, and diverse mechanical purposes. Additionally, their exceptional resistance to heat and corrosion makes them suitable for extreme conditions. In contrast, rubber round bars, composed of synthetic or natural rubber compounds, possess exceptional advantages such as flexibility, elasticity, and vibration absorption properties. These attributes make them ideal for applications necessitating shock absorption, noise reduction, or effective sealing. Automotive industries, machinery mounts, conveyor systems, and various other industrial fields extensively employ rubber round bars to leverage their distinctive properties. While steel round bars excel in strength and rigidity, rubber round bars offer impressive flexibility and vibration dampening capabilities. The choice between steel and rubber round bars primarily hinges on the specific requisites of the application. When high strength and durability are necessary, steel round bars emerge as the optimal selection. Conversely, if flexibility, elasticity, or vibration absorption are prerequisites, rubber round bars prove more suitable. To summarize, steel round bars and rubber round bars exhibit contrasting properties and applications. Steel round bars grant strength and durability, whereas rubber round bars provide flexibility and vibration absorption properties. Opting for one over the other relies on the specific requirements of the application.

- Q: The diameter of 20 solid round steel bend into a circle, what machine bending?

- Worm and worm type steel bar benderStructure: worm and worm type steel bending machine, mainly each family, motor, transmission system, work mechanism (work disk, insert seat, gripper, shaft, etc.) and control system. A walking wheel is arranged under the frame for easy movement.Working principle: the power of the motor is rotated by the V belt pulley, the two straight gear and the worm gear rod, and then drives the working disk to rotate. The working disk usually has 9 shafts, the center hole is used to insert the central shaft, and the 8 hole seats around each have 6 holes, which are used to insert the retaining shaft. In order to move the reinforcing steel bar, two times of each work table is also provided with a feeding roller. When working, according to the bending shape of the steel bar, the square of the reinforcing steel bar is arranged between the central axis of the work disc and the corresponding forming shaft, and the inner side of the iron block is blocked. When the working disc is rotated, one end of the reinforcing bar is prevented from rotating by the iron blocking shaft, the central shaft position is fixed, and the forming shaft is rotated in an arc direction around the central shaft, and the reinforcing bar is bent.As a result of the specification, the bending diameter of the steel bar shall be no less than 2.5 times of the diameter of the steel bar when it is taken as a 180 degree bending hook. Therefore, the center shaft is also made into 16~100mm in 9 different specifications to meet the requirements of bending different diameter steel bars.

- Q: Can steel round bars be used for making body panels?

- No, steel round bars are not typically used for making body panels. Body panels are usually made from sheet metal or aluminum, as they offer better flexibility, ease of shaping, and weight reduction compared to steel round bars.

- Q: Can steel round bars be used for making valves or fittings?

- Indeed, valves or fittings can be crafted using steel round bars. The utilization of steel is widespread in the production of valves and fittings owing to its commendable strength, resilience, and corrosion resistance. To cater to the specific criteria and demands, steel round bars can undergo machining or forging to attain the desired form for valves or fittings. Furthermore, heat treatment can be applied to steel round bars to bolster their mechanical attributes, rendering them suitable for applications involving elevated pressure or temperature. In conclusion, steel round bars present a versatile and dependable choice of material when it comes to manufacturing valves or fittings.

Send your message to us

S20C-B/S45C-B Steel Round Bar

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords