Special Steel Carbon Steel Round Bar S20C AISI 1020

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Information

◊ Standards and Chemical Composition:

Carbon Structural Steel Bar 20#(GB) | ||||||

Standards | Model | Chemical Composition (%) | ||||

C | Si | Mn | S(≤) | P(≤) | ||

GB | 20# | 0.17-0.23 | 0.17-0.37 | 0.35-0.65 | 0.035 | 0.035 |

DIN | C22(1.0402) | 0.17-0.24 | 0.40(max) | 0.40-0.70 | 0.045 | 0.045 |

BS | IC22 | 0.17-0.24 | 0.40(max) | 0.30-0.60 | 0.04 | 0.045 |

AISI/ATEM/SAE | 1020 | 0.18-0.23 | 0.15-0.35 | 0.30-0.60 | 0.05 | 0.03 |

JIS | S20C | 0.18-0.23 | 0.15-0.35 | 0.30-0.60 | 0.035 | 0.03 |

◊ Mechanical Property:

Carbon Structural Steel Bar 20#(GB) | |||||

Yield Strength(MPa) | Tensile Strength(MPa) | Elongation(%) | AKV(J) | Reduction in Area(%) | Hardness(HB) |

245 | 410 | 25 | 54 | 55% | 156 |

◊ Application:

We can see that the carbon steel bar has higher plasticity, better toughness and better welding performance. This kind of steel is good material in mading Lever shaft, Transmission shift folk, Heavy machinery trolley, Wheel gear, Mental loop, press forging parts, Rack rod, wear-resistant parts, for mold steel, etc.

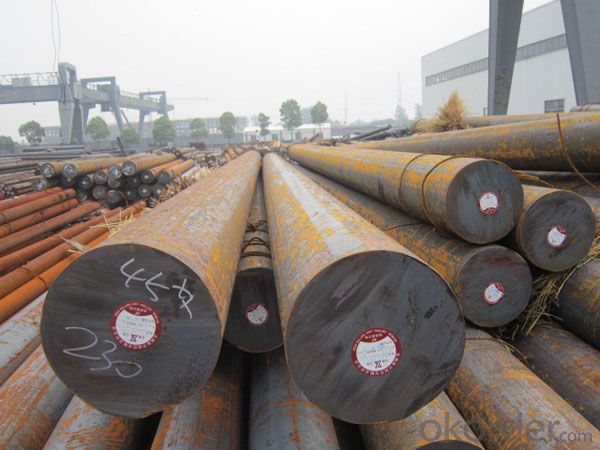

Product Show

Workshop Show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the different methods of improving the creep resistance of special steel?

- There are several methods of improving the creep resistance of special steel, which are designed to enhance its ability to withstand long-term exposure to high temperatures and constant stress. Some of the methods commonly employed include: 1. Alloying: Special steel can be alloyed with specific elements to enhance its creep resistance. The addition of elements such as chromium, molybdenum, tungsten, and vanadium can significantly improve the material's ability to resist creep deformation. These alloying elements form strong carbides or intermetallic compounds, which impede the movement of dislocations and enhance the material's strength and resistance to creep. 2. Heat treatment: Precise heat treatment techniques can be employed to improve the creep resistance of special steel. Processes such as quenching and tempering, annealing, and normalizing can alter the steel's microstructure, leading to the formation of fine-grained and homogeneous structures that offer improved creep resistance. Heat treatment also helps in relieving residual stresses and improving the material's overall strength. 3. Grain refinement: Special steel can be subjected to processes that refine its grain structure, thereby enhancing its creep resistance. Techniques such as grain size reduction through controlled rolling, recrystallization, and severe plastic deformation can lead to the formation of smaller and more uniform grains. This refined microstructure hinders dislocation movement and improves the material's resistance to creep deformation. 4. Precipitation hardening: Special steel can be subjected to precipitation hardening methods, where the material is heated and then rapidly cooled to induce the formation of fine precipitates. These precipitates act as barriers to dislocation movement, improving the material's strength and creep resistance. 5. Surface modification: Special steel can be treated with surface modification techniques to increase its creep resistance. Methods such as shot peening, laser surface melting, and surface coatings can improve the surface integrity, reduce surface roughness, and introduce compressive residual stresses, all of which contribute to enhanced creep resistance. It is important to note that the selection and combination of these methods depend on the specific requirements of the application and the type of special steel being used. The aim is to optimize the material's microstructure, chemical composition, and surface characteristics to achieve the desired creep resistance and ensure long-term performance at elevated temperatures.

- Q: Can special steel be used in the renewable energy industry?

- Yes, special steel can be used in the renewable energy industry. Special steel alloys are often used in the construction of wind turbines, solar panels, and hydroelectric power plants due to their high strength, corrosion resistance, and durability. These properties make special steel an ideal material for various components, such as turbine blades, tower structures, frames, and support systems, ensuring the reliability and longevity of renewable energy infrastructure.

- Q: How does special steel contribute to the aerospace defense industry?

- Special steel contributes to the aerospace defense industry by offering exceptional strength, durability, and corrosion resistance. It is used in the manufacturing of critical components, such as engine parts, landing gears, and structural elements, ensuring the safety and reliability of aircraft and defense systems. The high-performance properties of special steel enable the production of lighter aircraft, improving fuel efficiency and overall performance. Additionally, its ability to withstand extreme conditions and maintain structural integrity makes it crucial for military applications, including missile systems and armored vehicles.

- Q: What are the specific requirements for special steel used in the chemical industry?

- The specific requirements for special steel used in the chemical industry include corrosion resistance, high strength, and the ability to withstand extreme temperatures and pressures. Additionally, it should have excellent weldability and formability, as well as resistance to various chemicals and acids commonly found in chemical processes.

- Q: How is tool steel used in the manufacturing of molds and dies?

- Tool steel is used in the manufacturing of molds and dies due to its exceptional hardness, wear resistance, and toughness. It allows for the creation of precise and durable molds and dies that can withstand the high pressures and temperatures involved in various manufacturing processes. Tool steel also provides excellent dimensional stability, ensuring the accuracy and consistency of the final products.

- Q: What are the requirements for special steel used in agricultural machinery?

- The requirements for special steel used in agricultural machinery include high strength and durability to withstand heavy loads and harsh working conditions, excellent impact resistance to handle rough terrains, good corrosion resistance to protect against rust and moisture, and high wear resistance to prolong the lifespan of components exposed to abrasive materials. Additionally, the steel should have good weldability and machinability to facilitate the manufacturing process of agricultural machinery.

- Q: What is the process of manufacturing special steel?

- The process of manufacturing special steel involves several steps to ensure the production of high-quality and durable steel with specific properties. 1. Raw Materials Selection: The first step is to carefully select the raw materials required for making special steel. This includes iron ore, coal, and other alloying materials such as chromium, nickel, and manganese, depending on the desired properties of the final product. 2. Melting: The selected raw materials are then melted in a large furnace, often through the use of electric arc furnaces or basic oxygen furnaces. These furnaces heat the raw materials to extremely high temperatures, typically around 1,600 to 2,000 degrees Celsius, to transform them into molten metal. 3. Refining: Once the raw materials are melted, the molten metal undergoes a refining process to remove impurities. This is done through techniques like degassing, desulphurization, and deoxidation, ensuring that the steel is free from unwanted elements that may negatively impact its properties. 4. Alloying: After refining, alloying elements are added to the molten metal to achieve the desired properties. These elements can modify the steel's strength, hardness, corrosion resistance, and other characteristics. The specific alloying elements and their proportions depend on the intended application of the special steel. 5. Continuous Casting: The molten steel is then poured into a continuous casting machine, which solidifies it into semi-finished products called billets, blooms, or slabs. This continuous casting process ensures a consistent and uniform structure throughout the steel. 6. Hot Rolling: The semi-finished products are then reheated and passed through a series of hot rolling mills. This process involves reducing the thickness and shaping the steel into various forms such as bars, rods, plates, or sheets, depending on the intended use. 7. Heat Treatment: After hot rolling, the steel may undergo heat treatment processes such as annealing, quenching, tempering, or case hardening. These treatments help to further enhance the mechanical properties of the steel, such as its hardness, toughness, and ductility. 8. Finishing: The final step involves surface finishing and quality control measures. The steel is inspected for any defects or imperfections that may have occurred during the manufacturing process. Surface treatments like pickling or galvanizing can also be applied to enhance the steel's appearance and protect it from corrosion. Overall, the process of manufacturing special steel is a complex and precise operation that requires careful selection of raw materials, melting, refining, alloying, continuous casting, hot rolling, heat treatment, and finishing. This ensures that the resulting steel meets the specific requirements and performance characteristics demanded by various industries.

- Q: How does special steel withstand extreme temperatures?

- Due to its unique composition and production process, special steel possesses the ability to endure extreme temperatures. An essential factor in achieving this is the incorporation of alloying elements such as chromium, molybdenum, and nickel, which enhance the steel's resistance to heat. These elements react to form stable oxides on the steel's surface, forming a protective shield against oxidation and corrosion at high temperatures. Furthermore, special steel undergoes specific heat treatment methods like quenching and tempering, which refine its microstructure and enhance its mechanical properties. This process strengthens the steel, enabling it to maintain its strength and hardness even under harsh temperature conditions. In addition, the manufacturing process of special steel requires precision and control over the cooling rate. This controlled cooling prevents the formation of brittle phases, ensuring that the steel maintains its toughness and ductility at both high and low temperatures. Moreover, the grain size of special steel is meticulously regulated through techniques like grain refinement, resulting in a more uniform and fine-grained microstructure. This fine-grained structure enhances the steel's ability to resist thermal fatigue and creep, enabling it to endure prolonged exposure to extreme temperatures without significant degradation. Overall, the combination of alloying elements, specialized heat treatment processes, controlled cooling, and refined microstructure renders special steel highly capable of withstanding extreme temperatures while preserving its structural integrity and mechanical properties.

- Q: How is alloy steel different from carbon steel?

- Alloy steel differs from carbon steel in that it contains additional elements, such as nickel, chromium, or molybdenum, which enhance its strength, hardness, and corrosion resistance. This makes alloy steel more suitable for applications that require high performance and durability, while carbon steel is typically used for general-purpose applications.

- Q: How does special steel perform in terms of hardness?

- Special steel performs exceptionally well in terms of hardness. Due to its unique alloy composition and precise manufacturing process, it exhibits superior hardness compared to conventional steel. This enhanced hardness allows special steel to withstand high pressures, resist wear and tear, and provide excellent performance in demanding applications across various industries.

Send your message to us

Special Steel Carbon Steel Round Bar S20C AISI 1020

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords