Carbon Additve Low Ash Best Quality for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

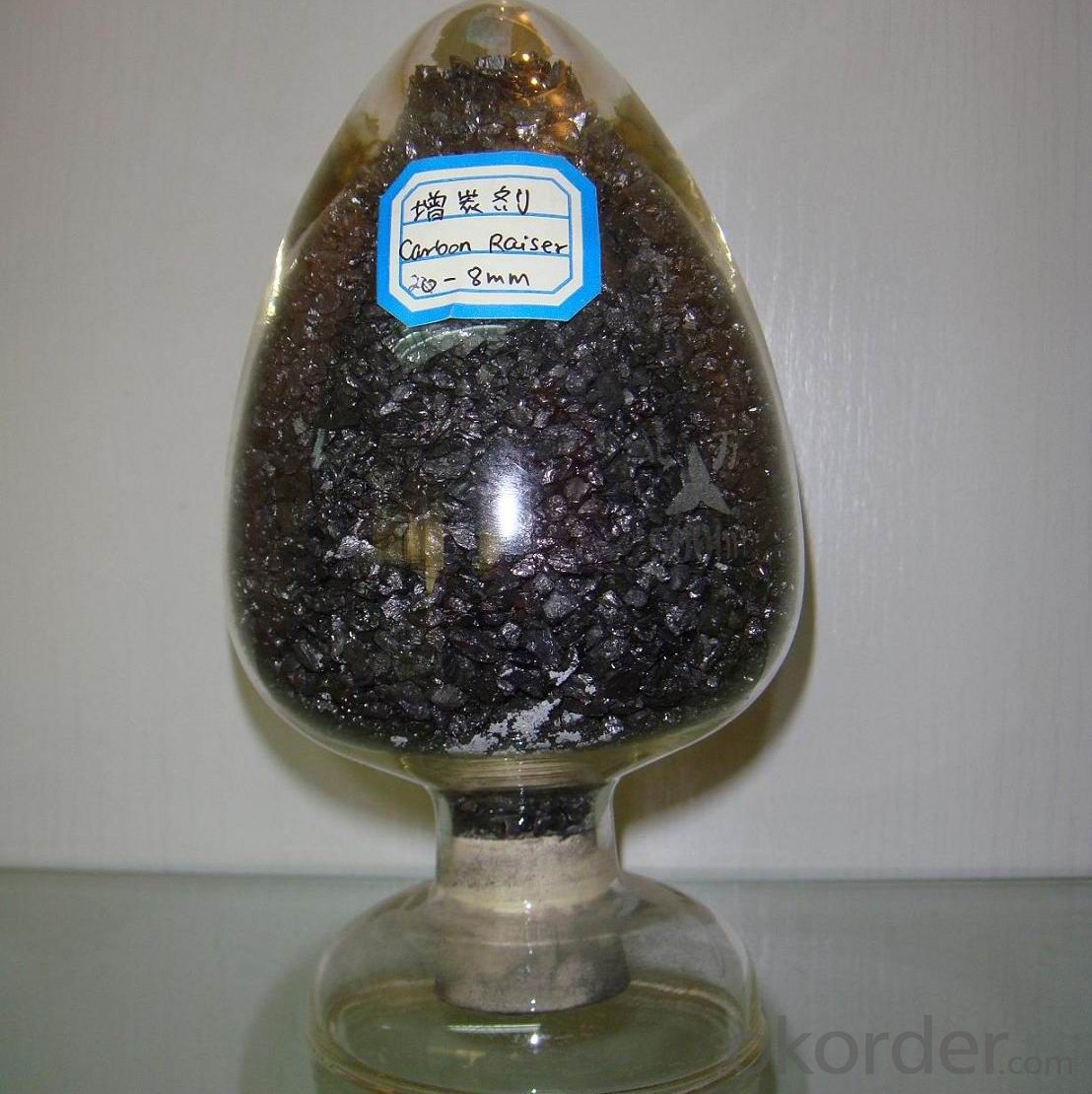

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

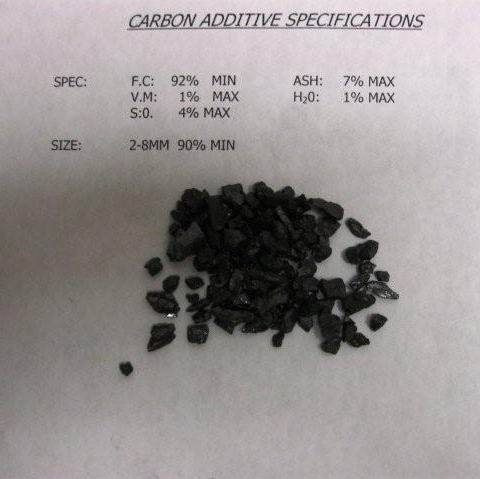

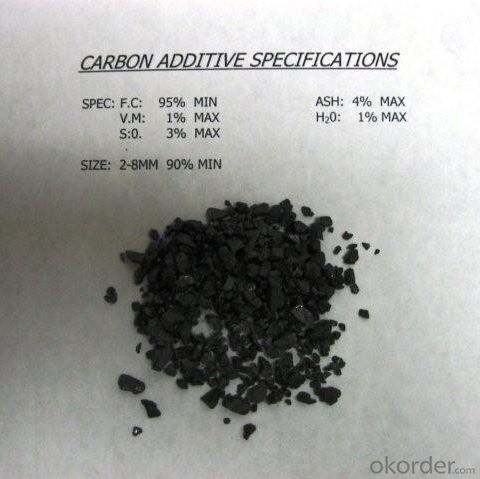

Specifications Carbon Additve Low Ash Best Quality Carbon Additve low Ash,S,P Structure Carbon Additve Low Ash Best Quality Shape: granule Dimensions: FC90-95% Product Type: Carbon Additive C Content (%): 90-95% MIN Working Temperature: - S Content (%): 0.5%MAX N Content (%): - H Content (%): 0.6%MAX Ash Content (%): 8.5%MAX Volatile: 2%MAX ADVANTAGE: low ash & sulfur COLOR: Black RAW MATERIAL: TaiXi anthracite Feature Carbon Additive Low Ash Best Quality Image Carbon Additive Low Ash Best Quality FAQ: Why we adopt carbon additive? Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation. Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking. Advantage: Carbon Additive Low Ash Best Quality 1.High quality and competitive price. 2.Timely delivery. 3.If any item you like. Please contact us. Your sincere inquiries are typically answered within 24 hours.

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost Specifications (%): Grade F.C Ash V.M Moisture S Size CR-95 ≥95 <4 <1 <1 <0.3 0-30mm

As buyer's request.CR-94 ≥94 <4 <1 <1 <0.3 CR-93 ≥93 <6 <1 <1 <0.4 CR-92 ≥92 <7 <1 <1 <0.4 CR-91 ≥91 <8 <1 <1 <0.4 CR-90 ≥90 <8.5 <1.5 <2 <0.4

- Q: What are the health effects of carbon pollution?

- Carbon pollution, specifically in the form of carbon dioxide (CO2) emissions, has a range of health effects on both humans and the environment. The primary health concern associated with carbon pollution is its contribution to climate change. As CO2 is a greenhouse gas, it traps heat in the Earth's atmosphere, leading to global warming and subsequently altering weather patterns. This can result in more frequent and severe heatwaves, hurricanes, and other extreme weather events. These events have direct and indirect health impacts, including heat-related illnesses, injuries, displacement, and the spread of infectious diseases. Furthermore, carbon pollution is closely linked to air pollution, which has significant health consequences. The burning of fossil fuels, such as coal and oil, releases not only CO2 but also a range of toxic air pollutants, including sulfur dioxide, nitrogen oxides, particulate matter, and volatile organic compounds. These pollutants can cause respiratory problems, such as asthma, bronchitis, and other chronic obstructive pulmonary diseases (COPD). Additionally, they can trigger cardiovascular issues and increase the risk of heart attacks and strokes. The health effects of carbon pollution are not limited to the respiratory and cardiovascular systems. Increased temperatures and changes in precipitation patterns can also impact water and food supplies, leading to waterborne diseases, reduced crop yields, malnutrition, and food insecurity. Moreover, the environmental consequences of carbon pollution, such as deforestation and ocean acidification, further exacerbate health risks. Deforestation reduces the availability of clean air and the natural carbon sinks that absorb CO2, while ocean acidification damages marine ecosystems, affecting the availability of fish and other seafood, which are vital sources of nutrition for many communities. To mitigate the health effects of carbon pollution, it is essential to reduce greenhouse gas emissions by transitioning to cleaner and renewable energy sources, implementing energy-efficient practices, and adopting sustainable land-use and agricultural practices. Additionally, investing in healthcare systems and public health infrastructure to address the direct and indirect health impacts of carbon pollution is crucial.

- Q: Appearance, hardness, electrical conductivity, use of carbon 60

- C60 does not normally conduct electricity because C60 is so large that it can put other atoms into it and affect its physical properties, so it cannot be electrically conductiveUsed to strengthen metalImprove the metal material strength by alloying, plastic deformation and heat treatment, one of the ways to strengthen the interaction through geometry, such as coke carbon dispersed in the metal, carbon and metal exchange position in the crystal lattice, can cause plastic deformation of metal, carbon and metal carbide particles that can make the metal enhanced. In the enhancement of metal materials, the effect of C60 ratio of carbon in coke is better, this is because the C60 is higher than the smaller particles, active carbon, particle size of C60 with metal carbide dispersion effect is 0.7nm, and the particle size of carbon and metal carbide dispersion effect the body is 2 m ~ 5 m, has a larger difference in enhancing the role of the metal.Used as a new catalystIn C60, the electronic structure of chemists began to explore the possibility of.C60 catalyst for C60 with olefin, with transition metal (such as platinum and nickel metal) to form a series of complexes. For example C60 and platinum, osmium can be combined into {[(C2H5) 3P]2Pt}C60 and C60OsO4 (four butylpyridine) and other coordination compounds and they are likely to become the efficient catalyst.Japanese researchers Toyohashi University of science and technology of the synthesis of highly catalytic activity of palladium Pt synthesis researchers and C60 compound C60Pd6. China Wuhan University (PPh3) 2C60 (PPh3 three, triphenylphosphine) for hydrosilylation reaction with high catalytic activity.

- Q: How can I see if a battery can be used to recharge it?Can not all carbon batteries charge?

- Final conclusion:Carbon batteries, alkaline batteries are not charged, the voltage is 1.5V, nickel cadmium batteries, nickel hydrogen batteries can charge voltage 1.2VPay special attention to the risk of leakage or explosion if you charge to a carbon battery or alkaline battery

- Q: What are the impacts of carbon emissions on human respiratory diseases?

- Human respiratory diseases are significantly affected by carbon emissions, especially those resulting from the burning of fossil fuels. The release of carbon dioxide and other greenhouse gases into the atmosphere contributes to climate change, which in turn impacts air quality and worsens respiratory conditions. One of the main outcomes of carbon emissions is the rise in air pollution. When fossil fuels are burned, various pollutants such as nitrogen oxides, sulfur dioxide, and particulate matter are released. These pollutants can irritate and harm the respiratory system, triggering and worsening respiratory diseases like asthma, bronchitis, and chronic obstructive pulmonary disease (COPD). They can also lead to the development of respiratory infections and reduce lung function, making individuals more susceptible to respiratory illnesses. Respiratory health is further affected by climate change, which is fueled by carbon emissions. As temperatures rise and weather patterns change, allergens and air pollutants proliferate, causing more frequent and severe allergic reactions and exacerbating respiratory conditions. Climate change can also extend the pollen season and increase the production of mold spores, leading to asthma attacks and other respiratory symptoms. Additionally, carbon emissions contribute to the creation of ground-level ozone, a harmful pollutant. Climate change enhances the chemical reactions that produce ozone due to higher temperatures and increased sunlight. Ground-level ozone can irritate the airways, resulting in coughing, shortness of breath, and chest pain. It can also worsen existing respiratory diseases and impair lung function, particularly in vulnerable populations such as children, the elderly, and individuals with pre-existing respiratory conditions. In conclusion, the impact of carbon emissions on human respiratory diseases is significant. They contribute to air pollution, which worsens respiratory conditions and increases the risk of respiratory infections. Furthermore, climate change, driven by carbon emissions, intensifies the production of allergens and air pollutants, exacerbating respiratory symptoms and reducing lung function. It is crucial to implement effective measures to reduce carbon emissions not only to address climate change but also to protect respiratory health.

- Q: How does carbon impact the pH balance of oceans?

- Carbon dioxide (CO2) dissolved in seawater reacts with water molecules to form carbonic acid, which lowers the ocean's pH. This decrease in pH, known as ocean acidification, has detrimental effects on marine life, especially organisms that rely on calcium carbonate to build their shells or skeletons. It disrupts the delicate balance of the marine ecosystem, affecting the growth, reproduction, and survival of various species, ultimately posing a threat to the biodiversity and health of our oceans.

- Q: What's the difference between blue and red Panasonic batteries (carbon)?

- Blue is leak, proof, general, Purpose, general use battery (leak proof)Red is the long life long life battery (suitable for watches and clocks and other small power appliances)And heavy duty green seems to be good for high power appliances, such as toy cars

- Q: What are the consequences of increased carbon emissions on tourism industry?

- Increased carbon emissions have significant consequences on the tourism industry. One of the most prominent effects is the deterioration of natural landscapes and ecosystems that attract tourists. Carbon emissions contribute to global warming, resulting in rising temperatures, melting glaciers, and increased instances of extreme weather events like hurricanes and droughts. These environmental changes can lead to the destruction of iconic landmarks, such as coral reefs or national parks, which are often the main attractions for tourists. Furthermore, increased carbon emissions contribute to air pollution, which can negatively impact air quality in popular tourist destinations. Poor air quality can lead to respiratory issues and other health problems for both tourists and local populations, making these places less desirable to visit. Additionally, the degradation of natural environments due to carbon emissions can also affect wildlife, leading to a decline in biodiversity. This loss of wildlife can reduce the appeal of ecotourism destinations, which heavily rely on the presence of diverse flora and fauna. Moreover, the tourism industry heavily relies on transportation, which is a significant source of carbon emissions. The use of fossil fuels in planes, ships, and cars contributes to the overall carbon footprint of the industry. As countries strive to reduce their carbon emissions, they may impose stricter regulations or taxes on air travel, making it more expensive and less accessible for travelers. This can impact the number of tourists visiting different destinations and hinder the growth of the tourism industry. Lastly, the consequences of increased carbon emissions extend beyond environmental factors. Climate change and extreme weather events can disrupt travel plans, leading to cancellations and financial losses for both tourists and businesses in the tourism industry. Moreover, destinations that heavily rely on winter tourism, such as ski resorts, may face challenges due to shorter snow seasons or inconsistent snowfall patterns caused by climate change. In conclusion, increased carbon emissions have severe consequences on the tourism industry. From the degradation of natural landscapes and ecosystems to the impact on air quality and wildlife, the effects of carbon emissions can deter tourists from visiting certain destinations. Additionally, the reliance of the tourism industry on transportation contributes to its overall carbon footprint, potentially leading to increased costs and reduced accessibility for travelers. Climate change-related disruptions and financial losses further compound the challenges faced by the tourism industry.

- Q: What are the different methods of measuring carbon dioxide levels in the atmosphere?

- Some of the different methods of measuring carbon dioxide levels in the atmosphere include: 1) Ground-based stations: These are fixed monitoring stations that collect air samples and measure carbon dioxide concentrations using gas analyzers. 2) Aircraft measurements: Scientists use aircraft equipped with sensors to sample air at different altitudes and locations to gather data on carbon dioxide levels. 3) Satellite observations: Satellites equipped with remote sensing instruments measure the concentration of carbon dioxide in the atmosphere from space. 4) Oceanic measurements: Researchers collect water samples from various depths in the ocean to analyze carbon dioxide levels and understand its absorption by the oceans. 5) Ice core analysis: By drilling and analyzing ice cores from glaciers and ice sheets, scientists can reconstruct carbon dioxide levels over thousands of years. These methods provide complementary data to understand the distribution and changes in carbon dioxide levels in the atmosphere.

- Q: What is carbon fiber and how is it used?

- Made from thin strands of carbon atoms bonded together in a specific pattern, carbon fiber is a material that is both lightweight and incredibly strong. Its exceptional strength-to-weight ratio surpasses that of steel, while its weight is significantly lighter. The unique properties of carbon fiber make it widely used across various industries and applications. In the aerospace industry, it is a common choice for constructing aircraft components such as wings, fuselage sections, and engine parts. Its strength and lightness contribute to better fuel efficiency and overall performance. The automotive industry heavily relies on carbon fiber for manufacturing high-performance vehicles. Carbon fiber reinforced composites are utilized in the production of body panels, chassis components, and interior trims. By reducing the overall weight of vehicles, carbon fiber not only enhances structural integrity but also improves handling and fuel efficiency. Sports equipment manufacturers also incorporate carbon fiber into the production of sporting goods like tennis rackets, golf clubs, bicycles, and hockey sticks. The material's strength and stiffness result in improved performance, increased power transfer, and enhanced durability. Additionally, carbon fiber finds applications in the construction industry for reinforcing concrete structures, as well as in the manufacturing of wind turbine blades, boat hulls, and various other industrial components. Overall, carbon fiber is the preferred choice in industries requiring high-performance materials due to its exceptional strength, lightweight nature, and versatility. As advancements in manufacturing techniques and cost reduction efforts continue, its use is expanding to a wider range of applications.

- Q: What is the significance of the determination of total organic carbon in purified water?

- The first tube with 5 drops of nitric acid and silver nitrate solution 1ml second tube plus barium chloride solution 2ml third tube plus ammonium oxalate solution 2ml, are not allowed to turbidity. Take this product 5ml nitrate test tube, in ice bath cooling, adding 10% potassium chloride solution and 0.1% 0.4ml aniline two 0.1ml sulfuric acid solution, then slowly adding sulfuric acid 5ml, shake the tube in 50 DEG C water bath for 15 minutes, the solution with the standard blue nitrate solution [for potassium nitrate 0.163g, dissolved in water and diluted to 100ml, shake, precise amount of water into 1ml, 100ml, then the precise amount of water into 10ml, 100ml, and the (per 1ml equivalent to 1 gNO3]0.3ml), with no nitrate water 4.7ml, compared with the same method after color not more, (0.000006%). Nitrite to take this product 10ml, the Nessler tube, and sulfanilamide dilute hydrochloric acid solution (1, 100) and 1ml hydrochloride Naphthylethylenediamine (0.1 - 100) 1ml solution, the pink, and the standard solution of sodium nitrite and nitrite [0.750g (calculated on dry goods), dissolved in water, dilute to 100ml, shake, precise amount of water into 1ml, 100ml, and then precise amount of water into 1ml, 50ml, and the (equivalent to 1 gNO2 per 1ml) 0.2ml), plus nitrite free water 9.8ml, compared with the same method after color, shall not be deeper (.000002%). Take this product 50ml ammonia, alkaline potassium tetraiodomercurate solution 2ml, placed 15 minutes; such as color, with ammonium chloride solution (from ammonium chloride 31.5mg, and no amount of ammonia dissolved and diluted into 1000ml 1.5ml), compared with alkaline solution and free ammonia 48ml iodine potassium iodide solution made from 2ml, not deeper (0.00003%).

Send your message to us

Carbon Additve Low Ash Best Quality for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches