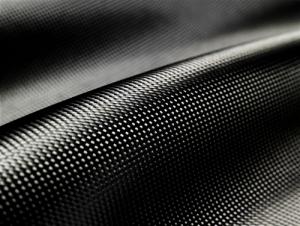

Carbon Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Carbon Fiber Fabric

Smooth and equally Carbon fiber fabric / ClotSize:1K,3K,6K,12K

Weight:100g/sqm~640g/sqm Weave:plain/twill/satin

General Data of Carbon Fiber Fabric

|

Tow Size |

Tow Count/CM |

Weave Style |

WidthRange (mm) |

Std. Width (mm) |

Thickness (mm) |

FAW (g/sq.m) |

FAW (oz/sq.yd) |

|

3K |

4 x 4 |

Plain |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

4 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.16 |

160 |

4.72 |

|

3K |

5 x 4 |

Plain |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 4 |

2x2 Twill |

10~1500 |

1000 |

0.18 |

180 |

5.31 |

|

3K |

5 x 5 |

Plain |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 5 |

2x2 Twill |

10~1500 |

1000 |

0.2 |

200 |

5.90 |

|

3K |

5 x 6 |

Plain |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

5 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.22 |

220 |

6.49 |

|

3K |

6 x 6 |

Plain |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

6 x 6 |

2x2 Twill |

10~1500 |

1000 |

0.24 |

240 |

7.08 |

|

3K |

8 x 8 |

Plain |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

2x2 Twill |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

|

3K |

8 x 8 |

8H Satin |

10~1500 |

1000 |

0.32 |

320 |

9.44 |

Storage of Carbon Fiber Fabric

It is recommended that the carbon fiber fabric are stored in a cool and dry environment. Recommended temperature range of storage is between 10 ~ 30 degree and relative humidity between 50 ~ 75%.The carbon fiber fabric should remain in the packaging until just prior to use.

Packaging & Delivery of Carbon Fiber Fabric

Product is manufactured in form of a roll wound on a paper tube and then packed in a plastic film and placed within a cardboard carton. Rolls can be loaded into a container directly or on pallets.

Packaging Detail: carton

Delivery Detail: within 20 days

- Q: What are the effects of ocean acidification on marine life?

- Ocean acidification is a significant issue that poses numerous detrimental effects on marine life. The primary cause of this phenomenon is the increase in carbon dioxide (CO2) emissions, which are absorbed by the oceans, leading to a decrease in pH levels. As the ocean becomes more acidic, it has profound consequences for various marine organisms and ecosystems. One of the most vulnerable groups impacted by ocean acidification is shell-forming organisms, such as corals, mollusks, and some types of plankton. The increasing acidity reduces the availability of carbonate ions, a vital component for these organisms to build and maintain their shells or skeletons. As a result, their growth and development are hindered, making them more susceptible to predation and extinction. This not only affects these individual species but also disrupts the entire food web, as they serve as a crucial food source for many other marine organisms. Furthermore, ocean acidification has adverse effects on various marine organisms' physiology and behavior. Studies have shown that it can impair the ability of fish to detect predators, find food, and navigate, which can lead to reduced survival rates and altered migratory patterns. Additionally, acidification can disrupt reproductive processes, such as the growth and survival of fish larvae, leading to population declines and reduced biodiversity. Coral reefs, often referred to as the "rainforests of the sea," are particularly vulnerable to ocean acidification. The increased acidity inhibits the calcification process essential for coral growth, making them more susceptible to bleaching and death. As coral reefs provide crucial habitats for numerous marine species, their decline would have cascading effects on the entire ecosystem. Lastly, ocean acidification also impacts the balance of marine ecosystems by altering the composition and abundance of various species. Some organisms, such as certain types of algae, may actually benefit from increased CO2 levels and thrive, leading to an imbalance in the ecosystem. This can result in the dominance of certain species, negatively impacting the overall biodiversity and stability of the marine environment. In conclusion, ocean acidification poses significant threats to marine life. It disrupts the growth and development of shell-forming organisms, impairs the physiology and behavior of various marine species, damages coral reefs, and alters the composition of marine ecosystems. Addressing this issue is crucial to protect marine biodiversity, sustain fisheries, and maintain the overall health of our oceans.

- Q: What kinds of barbecue carbon do you have?

- Common carbon on the market are: flammable carbon, charcoal, carbon three mechanisms. Flammable carbon available in outdoor stores, there are two kinds of square and pie. The surface of flammable carbon has a flammable layer, which is easier to ignite than ordinary charcoal.

- Q: What are the advantages of carbon-based batteries?

- Carbon-based batteries, such as alkaline batteries, have become a popular choice in various applications due to their numerous advantages. Firstly, their longer shelf life sets them apart from other battery types. They have the ability to retain their charge for extended periods, making them particularly suitable for devices that are infrequently used or for emergency situations. In addition, carbon-based batteries offer a higher energy density, enabling them to store more energy in a compact package. This makes them lightweight and convenient for portable electronic devices like smartphones, laptops, and cameras. Moreover, these batteries have a lower self-discharge rate, meaning they lose less charge over time when not in use. As a result, they can maintain their power for longer periods without the need for frequent recharging or replacement. Furthermore, carbon-based batteries possess a higher discharge rate, allowing them to deliver power quickly when required. This is especially advantageous for devices that demand a sudden burst of energy or for high-drain applications like digital cameras or power tools. Another notable advantage of carbon-based batteries is their cost-effectiveness. They are readily available, inexpensive to produce, and can be easily recycled, thereby reducing their environmental impact. In conclusion, carbon-based batteries offer a range of benefits, including a longer shelf life, higher energy density, lower self-discharge rate, higher discharge rate, cost-effectiveness, and environmental friendliness. These features make them a reliable and efficient choice for a wide array of electronic devices and applications.

- Q: What are the impacts of carbon emissions on human health in developing countries?

- The impacts of carbon emissions on human health in developing countries can be significant. Exposure to high levels of carbon emissions, particularly from sources such as vehicle exhaust, industrial pollution, and inefficient cooking fuels, can lead to various health problems. These include respiratory issues like asthma, bronchitis, and lung cancer, as well as cardiovascular diseases, allergies, and compromised immune systems. Additionally, carbon emissions contribute to the formation of smog and air pollution, which further worsen these health conditions. Developing countries often lack the resources and infrastructure to effectively mitigate these emissions, making their populations more vulnerable to the adverse health effects of carbon emissions.

- Q: How does carbon impact biodiversity?

- Carbon impacts biodiversity in several ways. Firstly, carbon dioxide is a greenhouse gas that contributes to climate change, leading to shifts in temperature and precipitation patterns. These changes can disrupt ecosystems and alter habitats, affecting the distribution and survival of various species. Additionally, excess carbon in the atmosphere can lead to ocean acidification, which negatively affects marine biodiversity by harming coral reefs and other organisms reliant on calcium carbonate structures. Finally, deforestation and land-use changes associated with carbon emissions result in habitat loss, further reducing biodiversity. Overall, carbon emissions have significant and detrimental impacts on the delicate balance of ecosystems and the diversity of life on Earth.

- Q: How is carbon used in the production of adhesives?

- Carbon is used in the production of adhesives in several ways. One common method involves the use of carbon black, which is a fine powder made from the incomplete combustion of hydrocarbon fuels. Carbon black is added to adhesives to improve their strength, durability, and resistance to UV radiation. It acts as a reinforcing agent, increasing the adhesion and cohesion properties of the adhesive. Additionally, carbon fibers are sometimes incorporated into adhesives to further enhance their strength and mechanical properties. These fibers are made by heating and stretching synthetic fibers or natural materials like rayon or petroleum pitch. When added to adhesives, carbon fibers provide increased tensile strength and stiffness, making them ideal for applications that require high-performance adhesives. Moreover, carbon-based polymers, such as epoxies and polyesters, are widely used in adhesive formulations. These polymers are created through chemical reactions involving carbon-based monomers. They offer excellent bonding properties, high resistance to heat and chemicals, and can be tailored to specific application requirements. Furthermore, carbon-based resins can be modified with other additives and fillers to achieve specific characteristics, such as flexibility, impact resistance, or flame retardancy. In summary, carbon is utilized in the production of adhesives through the incorporation of carbon black, carbon fibers, and carbon-based polymers. These materials significantly enhance the strength, durability, and other properties of adhesives, making them suitable for a wide range of applications in industries such as automotive, construction, electronics, and aerospace.

- Q: Buy carbon carving, how to identify him is true or false, and the quality of good or bad?

- General consumers believe that bamboo charcoal, powder, charcoal and purple carbon carving are "carbon" to do, and the former is very cheap, why not buy them, in fact, otherwise, because not the same kind of products. Bamboo charcoal and powdered activated carbon have little effect on the purification of indoor air. Their function is not different from that of a pack of quicklime - adsorption of water vapor. But consumers are not aware of this, they also propaganda have the function of purifying air and we mixed together to sell, finally, once consumers buy found not what role, will also lose confidence in carving, which makes us very sad.Let's talk about bamboo charcoal first. Charcoal is not a purple carbon carving, this is a common sense. If bamboo charcoal can also absorb toxic and harmful gases, then the main material of gas masks do not need to use more expensive activated carbon, but not sublimation of purple carbon carving, and the price of bamboo charcoal is not economical? Because the bamboo charcoal and charcoal are natural burning carbon, not activated by directional adsorption, namely, pickling, washing, activation process, the adsorption of activated carbon 1/10 is insufficient, they can have is to adjust the indoor temperature, not only this, as they advertised "bamboo charcoal is activated carbon is purple carbon carving".Say, powdered activated carbon.

- Q: What's the difference between blue and red Panasonic batteries (carbon)?

- Blue is leak, proof, general, Purpose, general use battery (leak proof)Red is the long life long life battery (suitable for watches and clocks and other small power appliances)And heavy duty green seems to be good for high power appliances, such as toy cars

- Q: How does carbon affect the fertility of soil?

- Carbon is an essential element for soil fertility as it influences various soil properties and processes. When carbon is added to the soil, it helps improve its structure and water holding capacity. Organic matter, which is rich in carbon, serves as a food source for microorganisms, which in turn promote nutrient cycling and soil aggregation. These microorganisms break down organic matter into simpler compounds, releasing essential nutrients that are readily available for plants. Additionally, carbon also acts as a sponge, holding onto nutrients like nitrogen and preventing their leaching, thus enhancing nutrient availability for plants. Moreover, carbon-rich soils tend to have a higher cation exchange capacity, which means they can retain and release nutrients more effectively. By maintaining and increasing soil carbon levels, we can enhance soil fertility, promote plant growth, and support sustainable agriculture practices.

- Q: What are the properties of carbon-based rubber?

- Carbon-based rubber, also known as carbon black-filled rubber, possesses several important properties that make it highly desirable for various applications. Firstly, carbon-based rubber exhibits excellent elasticity and flexibility, allowing it to withstand repeated stretching and compression without permanent deformation. This property makes it ideal for use in manufacturing products such as tires, gaskets, and seals. Secondly, carbon-based rubber displays outstanding resistance to abrasion and wear, ensuring that it can endure harsh conditions and prolonged use without deteriorating. This property is particularly beneficial in applications where the rubber material is subjected to friction or constant contact with rough surfaces. Additionally, carbon-based rubber demonstrates remarkable resistance to various environmental factors. It has excellent resistance to ozone, sunlight, and weathering, making it suitable for outdoor applications where it will be exposed to UV radiation and extreme temperatures. Its resistance to chemicals and oils further enhances its versatility, allowing it to be used in industries such as automotive, aerospace, and manufacturing. Another noteworthy property of carbon-based rubber is its electrical conductivity. This characteristic makes it an ideal material for applications that require static dissipation or protection against electrostatic discharge, such as in electronic devices, conveyor belts, and industrial flooring. Furthermore, carbon-based rubber exhibits good adhesion to various substrates, enabling it to form strong bonds when used in adhesive applications or as a lining material. Overall, the properties of carbon-based rubber make it a highly sought-after material due to its exceptional elasticity, abrasion resistance, environmental resistance, electrical conductivity, and adhesion capabilities.

1. Manufacturer Overview

| Location | Jiangsu,China |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | Europe, America, Africa, Oceania and Japan, Korea, southeast Asia |

| Company Certifications | ISO9000 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Fiber Fabric

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 2 Ton kg

- Supply Capability:

- 500Ton Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords