Carbon Additve Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Place of Origin: Ningxia, China (Mainland)

Application: steel making

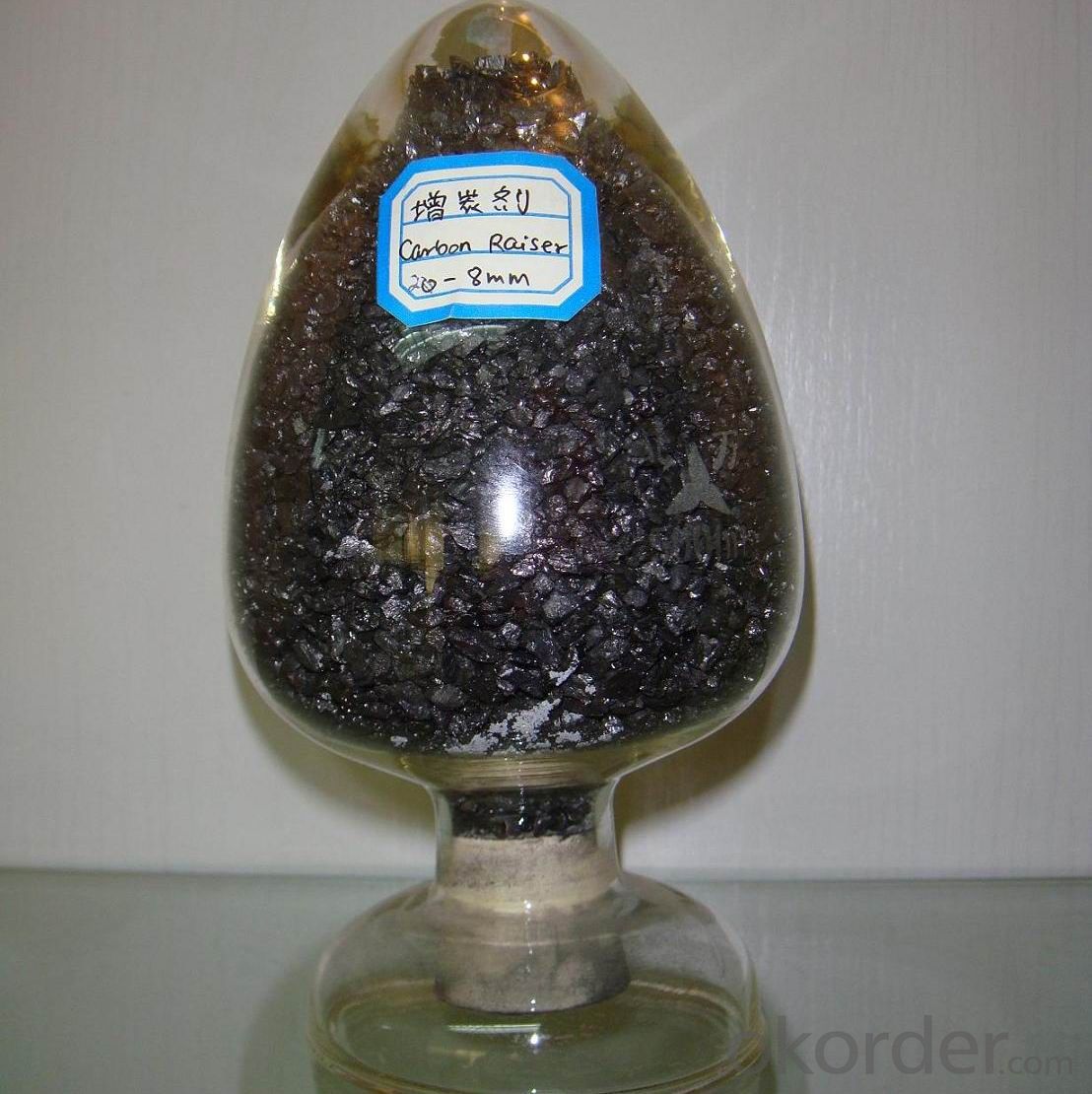

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Packaging & Delivery

| Packaging Details: | In 1MT plastic woven bag. |

|---|---|

| Delivery Detail: | 30-40DAYS |

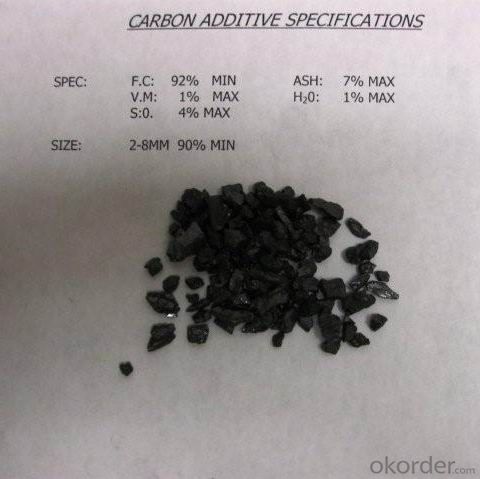

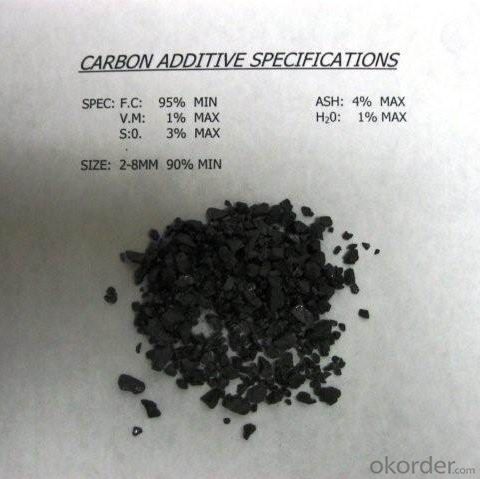

Specifications

Carbon Additve Low Sulphur for Steelmaking

Carbon Additve low Ash,S,P

FC>95% ASH<4% S<0.3%

It is made from TaiXi anthracite.

instead of pertrol coke reduce the cost

Structure

Carbon Additve Low Sulphur for Steelmaking

Shape: granule

Dimensions: FC90-95%

Product Type: Carbon Additive

C Content (%): 90-95% MIN

Working Temperature: -

S Content (%): 0.5%MAX

N Content (%): -

H Content (%): 0.6%MAX

Ash Content (%): 8.5%MAX

Volatile: 2%MAX

ADVANTAGE: low ash & sulfur

COLOR: Black

RAW MATERIAL: TaiXi anthracite

Feature

Carbon Additve Low Sulphur for Steelmaking

Specifications (%): | ||||||

Grade | F.C | Ash | V.M | Moisture | S | Size |

CR-95 | ≥95 | <4 | <1 | <1 | <0.3 | 0-30mm |

CR-94 | ≥94 | <4 | <1 | <1 | <0.3 | |

CR-93 | ≥93 | <6 | <1 | <1 | <0.4 | |

CR-92 | ≥92 | <7 | <1 | <1 | <0.4 | |

CR-91 | ≥91 | <8 | <1 | <1 | <0.4 | |

CR-90 | ≥90 | <8.5 | <1.5 | <2 | <0.4 | |

Image

Carbon Additve Low Sulphur for Steelmaking

FAQ:

Carbon Additve Low Sulphur for Steelmaking

Why we adopt carbon additive?

Carbon Additives used as additive in steel making process. It made from well-selected Tai Xi anthracite which is low in content of ash, sulphur, phosphorus, high heat productivity, high chemically activation.

Mainly industry property of it is: instead of traditional pertroleum coal of Carbon Additives, reduce the cost of steelmaking.

Advantage:

Carbon Additve Low Sulphur for Steelmaking

1.High quality and competitive price.

2.Timely delivery.

3.If any item you like. Please contact us.

Your sincere inquiries are typically answered within 24 hours.

- Q: In Japanese, what's the difference between adding "carbon" and "sauce" after the name?

- Just like Chinese children, when they were young, they said, "Uncle", because they are small and articulate. It is easy to say "ball ball".

- Q: What are the advantages and disadvantages of carbon monoxide and carbon dioxide?

- Using carbon dioxide instead of traditional organic solvents to spray paint can effectively reduce the amount of harmful substances released into the atmosphere during the process of spraying. In the high-tech, carbon dioxide has its use for laser treatment using carbon dioxide instead of helium neon, can reduce the pain of patients, and save the cost for carbon dioxide extraction of egg yolk lecithin, considerable economic benefit. Carbon dioxide can be used to wash clothes, and does not pollute the environment, but also a wide range of sources. These are all benefits. The downside is the increased carbon dioxide caused by the greenhouse effect, resulting in the polar melting glaciers, rising sea levels, threatening the coastal city, the land salinization of coastal areas, increasing the difficulty of development, increasing temperature also makes the melting of snow in some of the top of the hill, the snow melt water resources of river water to reduce or even stop the phenomenon to occur, the affected area production activities. The increase of the atmospheric temperature, resulting in carbon dioxide absorption in some marine algae wantonly breeding, resulting in the death of algae absorb carbon dioxide, indirectly affect the fishery breeding, and the carbon dioxide in the atmosphere increases toward the vicious spiral. Take | enthusiastic users on 2013-11-09 12:52

- Q: What are the effects of carbon emissions on the stability of ice shelves?

- Ice shelves are significantly affected by carbon emissions, which have a major impact on their stability. When carbon dioxide (CO2) and other greenhouse gases are released into the atmosphere, they trap heat and contribute to the phenomenon of global warming. This rise in global temperature leads to the melting of ice shelves and glaciers. One of the main consequences of carbon emissions on ice shelves is the acceleration of their melting rates. Higher atmospheric temperatures cause more ice to melt, resulting in a greater amount of water flowing into the ocean. This influx of freshwater can disturb the delicate equilibrium between the ice shelf and the ocean, potentially resulting in the collapse of the ice shelf. Furthermore, carbon emissions contribute to the thinning of ice shelves. As the atmosphere warms, the air temperature above the ice shelves increases, leading to increased surface melting. This meltwater then enters crevasses and cracks, causing further fracturing and weakening of the ice shelves. Over time, this thinning makes the ice shelves more vulnerable to breaking apart. The melting of ice shelves caused by carbon emissions also has indirect effects on the stability of surrounding ice sheets. Ice shelves act as a support, resisting the flow of ice from glaciers into the ocean. When ice shelves collapse or become thinner, this resistance decreases, allowing glaciers to flow more freely into the ocean. This process results in a rise in sea levels, which has significant implications for coastal regions worldwide. Moreover, the loss of ice shelves can disrupt the ecosystem and biodiversity of the surrounding areas. Ice shelves provide a platform for various species, such as seals and penguins, to breed and feed. When ice shelves disintegrate, these habitats are destroyed, impacting the entire food chain and the dynamics of the ecosystem. In conclusion, carbon emissions from human activities have a profound impact on the stability of ice shelves. The melting, thinning, and collapse of ice shelves contribute to the rise in sea levels, disrupt ecosystems, and have far-reaching consequences for coastal communities. It is crucial to reduce carbon emissions and take proactive measures to safeguard these vulnerable ice shelves and the delicate balance they uphold in our global climate system.

- Q: What are the impacts of carbon emissions on the stability of polar ice caps?

- Carbon emissions have significant impacts on the stability of polar ice caps. The primary cause of these emissions is the burning of fossil fuels, which releases large amounts of carbon dioxide into the atmosphere. As a greenhouse gas, carbon dioxide traps heat and contributes to global warming and climate change. This, in turn, leads to the melting of polar ice caps. The ice caps in the polar regions are highly sensitive to changes in temperature. As the Earth's temperature rises due to increased carbon emissions, the polar ice caps experience accelerated melting. This causes a rise in sea levels, which has consequences for coastal regions worldwide. Rising sea levels can lead to increased flooding, erosion, and the loss of valuable coastal ecosystems. Moreover, the stability of polar ice caps is crucial for maintaining the Earth's climate balance. The ice caps reflect sunlight back into space, acting as a natural cooling mechanism for the planet. As they melt, less sunlight is reflected, and more is absorbed by the Earth's surface, exacerbating the warming effect. This creates a feedback loop, where the melting of ice caps leads to further warming, causing even more ice to melt. The impacts of carbon emissions on polar ice caps are not limited to rising sea levels and climate change. The loss of ice also affects the delicate balance of ecosystems in these regions. Polar ice caps provide habitat and a food source for a diverse range of organisms, including polar bears, seals, and various species of birds. The melting of ice disrupts these ecosystems, leading to declines in wildlife populations and potential extinctions. Moreover, the melting of polar ice caps also affects global ocean currents and weather patterns. The cold, dense water that forms from melting ice sinks to the bottom of the ocean and drives important oceanic circulation patterns. Changes in these patterns can have far-reaching consequences, including altering the distribution of marine species, impacting fisheries, and influencing regional climates. To mitigate the impacts of carbon emissions on polar ice caps, it is crucial to reduce greenhouse gas emissions and transition to cleaner and renewable energy sources. International efforts, such as the Paris Agreement, aim to limit global warming and reduce carbon emissions to prevent further ice cap melting. Additionally, supporting research and monitoring programs in polar regions can help us better understand these complex systems and develop effective strategies for their conservation.

- Q: What is diamond?

- Diamond is a naturally occurring precious gemstone that is composed of carbon atoms arranged in a unique crystal lattice structure, known for its exceptional hardness, brilliance, and durability.

- Q: What are the advantages of carbon-based nanoelectronics?

- Carbon-based nanoelectronics have several advantages. Firstly, carbon is an abundant and versatile element, making it cost-effective and readily available for large-scale production. Secondly, carbon-based materials, such as graphene and carbon nanotubes, possess exceptional electrical, thermal, and mechanical properties, enabling high-performance and efficient devices. Additionally, carbon-based nanoelectronics offer excellent flexibility and transparency, allowing for the development of flexible and wearable electronic devices. Lastly, carbon-based materials exhibit excellent stability and biocompatibility, making them suitable for various applications, including biomedical devices and sensors. Overall, these advantages make carbon-based nanoelectronics a promising platform for future advancements in electronics.

- Q: But their chemical symbols are different, so they are different elements, different substances, but they feel the same thing... Tangled up ~!

- No one is the same. Lead is poisonous, and pencil lead is lead. The structure of carbon is the same as that of diamonds. Generally speaking, they are of structure, density and composition. No one is the same

- Q: How do you stick carbon fabric?

- 3. Apply the base resin(1) the main agent and curing agent base resin according to the provisions of the proportion accurate weighing were put into the container, use a blender to mix uniformly. A harmonic volume should be in use within the time spent more than can be used as the standard, time cannot be used.(2) apply the base coat evenly with a roller brush(3) refers to the drying time, due to different temperatures, generally between 3H to 1D changes(4) after the curing of the base coat, when the surface of the component has a condensation bulge, it should be polished with sandpaper. If the surface of the concrete is exposed after polishing, the bottom coating shall be applied again4, the incomplete repair of the surface of the componentThe surface depressions (honeycomb pits, holes, etc.) using epoxy putty to fill, to repair the surface. (the poor, camber angle etc.) to be filled with epoxy putty, so smooth.

- Q: What are the differences between the three carburizing, nitriding and carbonitriding? What are the different effects on the material?

- Carburizing: carburized workpiece after quenching and low temperature tempering, so that the surface has a high hardness of river abrasion resistance, and the heart still maintain a good plastic River toughness, so as to meet the workpiece outside the hard, internal use of tough requirementsNitriding: after the nitriding of the parts, the surface forms a nitride.

- Q: How can Dungeon Fighter Online's superior furnace rock carbon be obtained?

- Bought in cash. You can go to the mall to have a look.

Send your message to us

Carbon Additve Low Sulphur for Steelmaking

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches